• 22 •

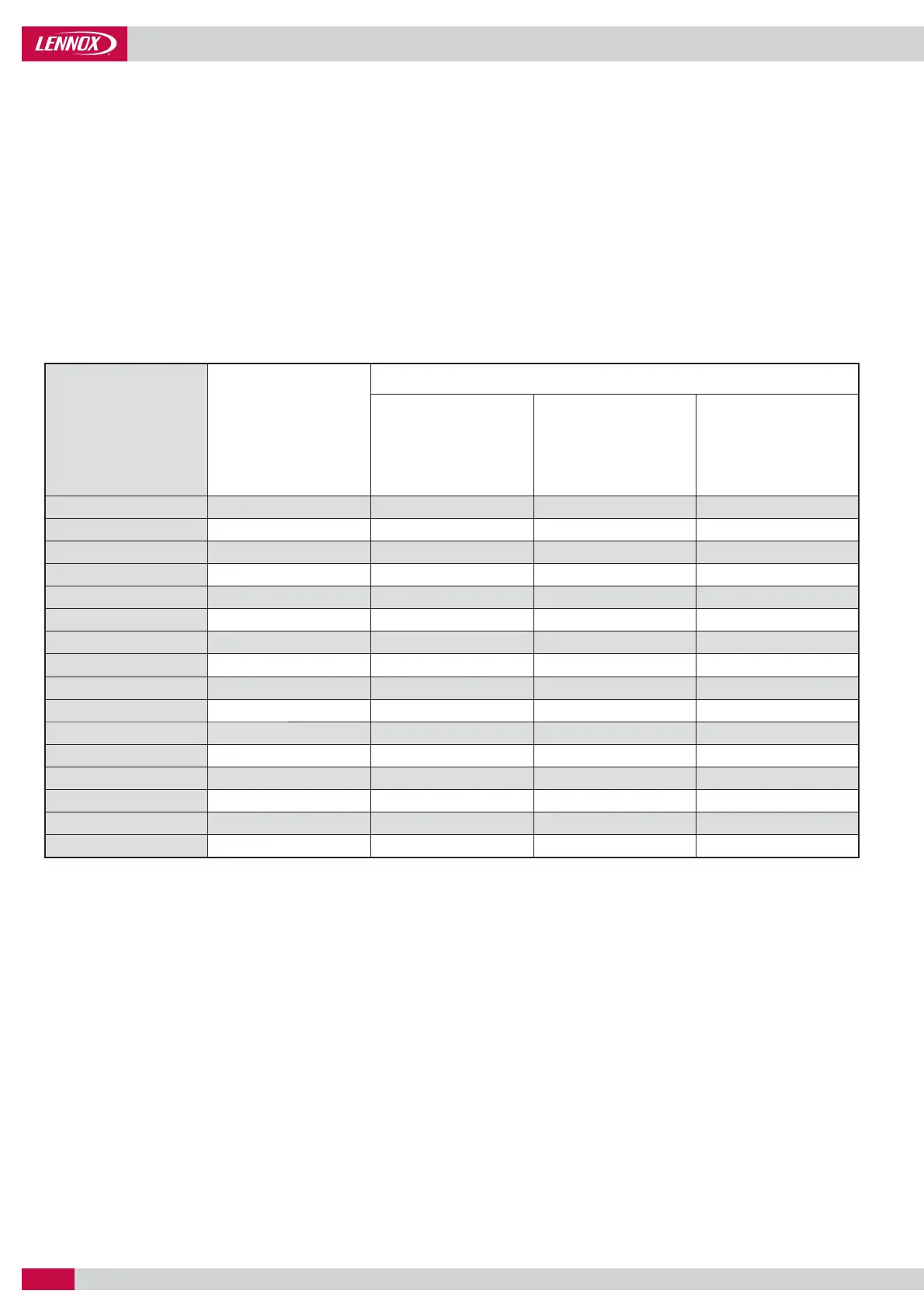

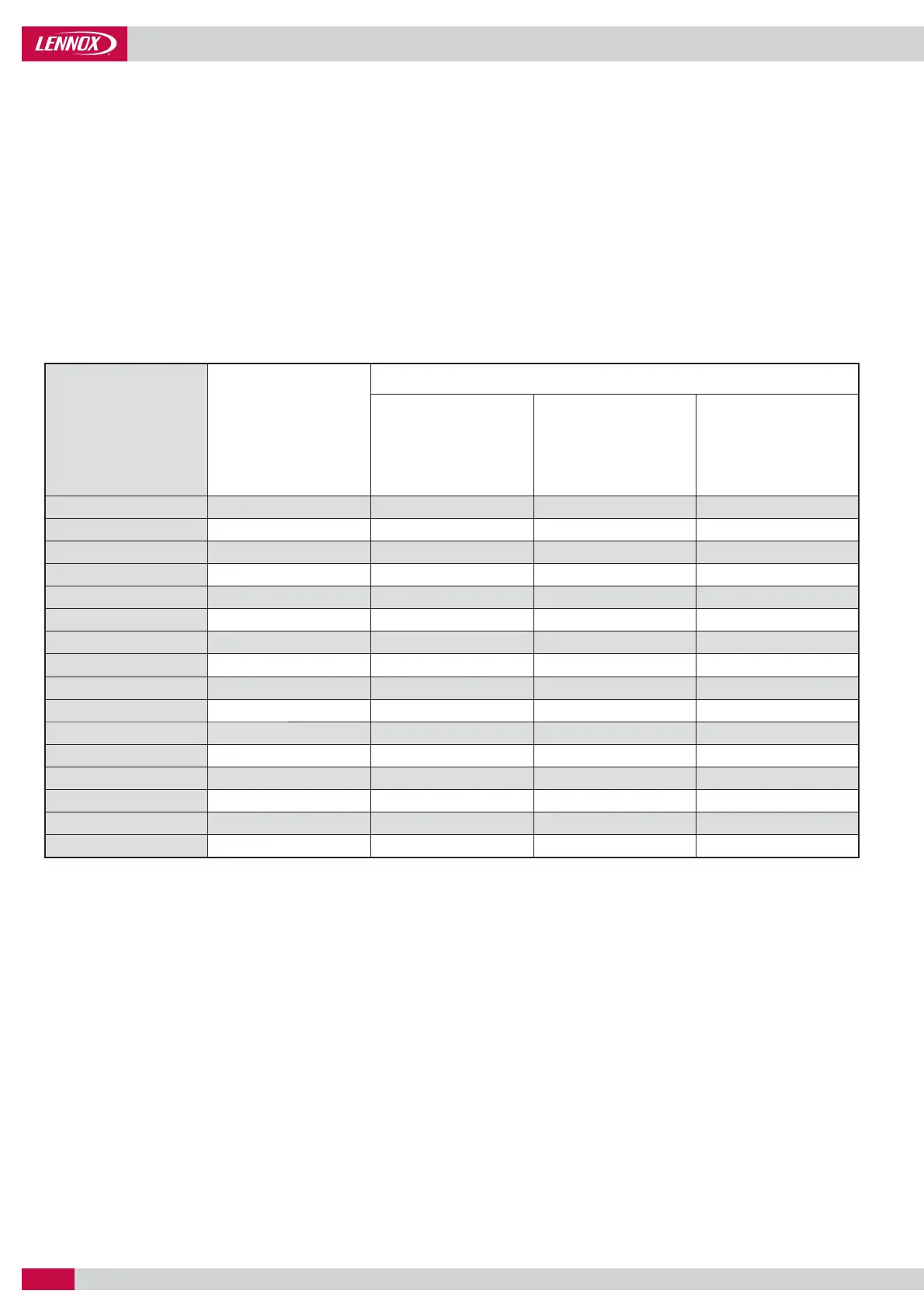

200

208 21,5 35,8 57,9

230

236 24,4 40,6 57,9

270

273 28,1 46,9 57,9

300

308 31,7 52,9 126,4

340

351 36,2 60,4 126,4

380

387 40,0 66,6 126,4

420

430 44,3 73,9 126,4

480

490 50,6 84,3 126,4

540

531 54,8 91,3 126,4

600

605 62,5 104,1 126,4

640

627 64,7 107,9 126,4

680

702 72,6 121,0 252,9

760

774 80,1 133,4 252,9

840

860 88,8 148,0 252,9

960

980 101,3 168,8 252,9

1080

1062 109,7 182,9 252,9

Application Guide / NEOSYS-AGU-1801-E

HYDRAULIC DATA

MINIMUM WATER FLOW THROUGH THE EVAPORATOR

In case of installation with fi xed speed pump, to prevent from freezing risk, the fl ow rate through the evaporator must be higher than

the minimum fl ow given in the table below.

In case of variable primary fl ow, the pump speed must be controlled through the CLIMATIC control. Additionally, the hydraulic system

must be properly designed and balanced to ensure a right water fl ow distribution through the chiller evaporator and the terminal units.

This is especially important when the system is designed with fan coils equipped with two-way valves. When the two-way valves are

closing in response to building load change, it is important that the system is designed to ensure a minimum evaporator fl ow that is

always minimum 60% of the chiller’s design fl ow rate. This can be done with a bypass from chilled water supply to chilled water return

opened via a signal from a fl ow meter.

Additionnaly, some terminals can be fi tted with three way control valves in order to ensure the fl ow will not drop below the minimum

value at any load condition as indicated in the table below.

Models Capacity (kW)

Water fl ow rate (m³/h)

Minimum

(with fi xed and eDrive™

variable speed pump)

Nominal Maximum

Important note : The water fl ow must not vary by more than 10% per minute. If the fl ow rate changes more rapidly, the system should

contain a minimum of 6,5 litres of water per kW instead of 3 l/kW.

Loading...

Loading...