Page 38

Burner runs continuously cont.

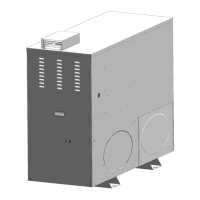

Source Procedure Causes Correction

Too much combustion air Reduce combustion air.

Air leaks into heat exchanger

around inspection door, etc.

Correct cause of air leak.

ow

2

ess

than 10%.

Excessive draft

Adjust barometric draft con

trol for correct draft.

Incorrect burner head adjust

ment

Correct burner head setting.

Dirty or plugged heat exchanger

Clean heat exchanger.

r

y or p

ugge

ea

exc

anger

Readjust burner.

High smoke

readin

more

Insufficient draft Increase draft.

Combustion

ec

urner

combustion for

CO2, stack tem

than a trace. Incorrect burner head adjust

ment

Correct burner setting.

perature, and

Too little combustion air Increase combustion air.

smo

e

Too little blower air

Increase blower speed to

maintain proper temp. rise.

Hi

h stack tem

Blower belt too loose (if

equipped)

Tighten blower belt.

perature is

Dirty or plugged heat exchanger Clean heat exchanger.

more t

an

550

F Net.

Dirty blower wheel Clean blower wheel.

Dirty furnace air filters Clean or replace filter.

Restricted or closed registers or

dampers

Readjust registers or damp

ers.

Inspect fire and check

Partially plugged or defective

nozzle

Replace nozzle.

ressure

oil pressure.

Oil pressure is too low: less

than 100 psi.

Increase oil pressure top

100psi.

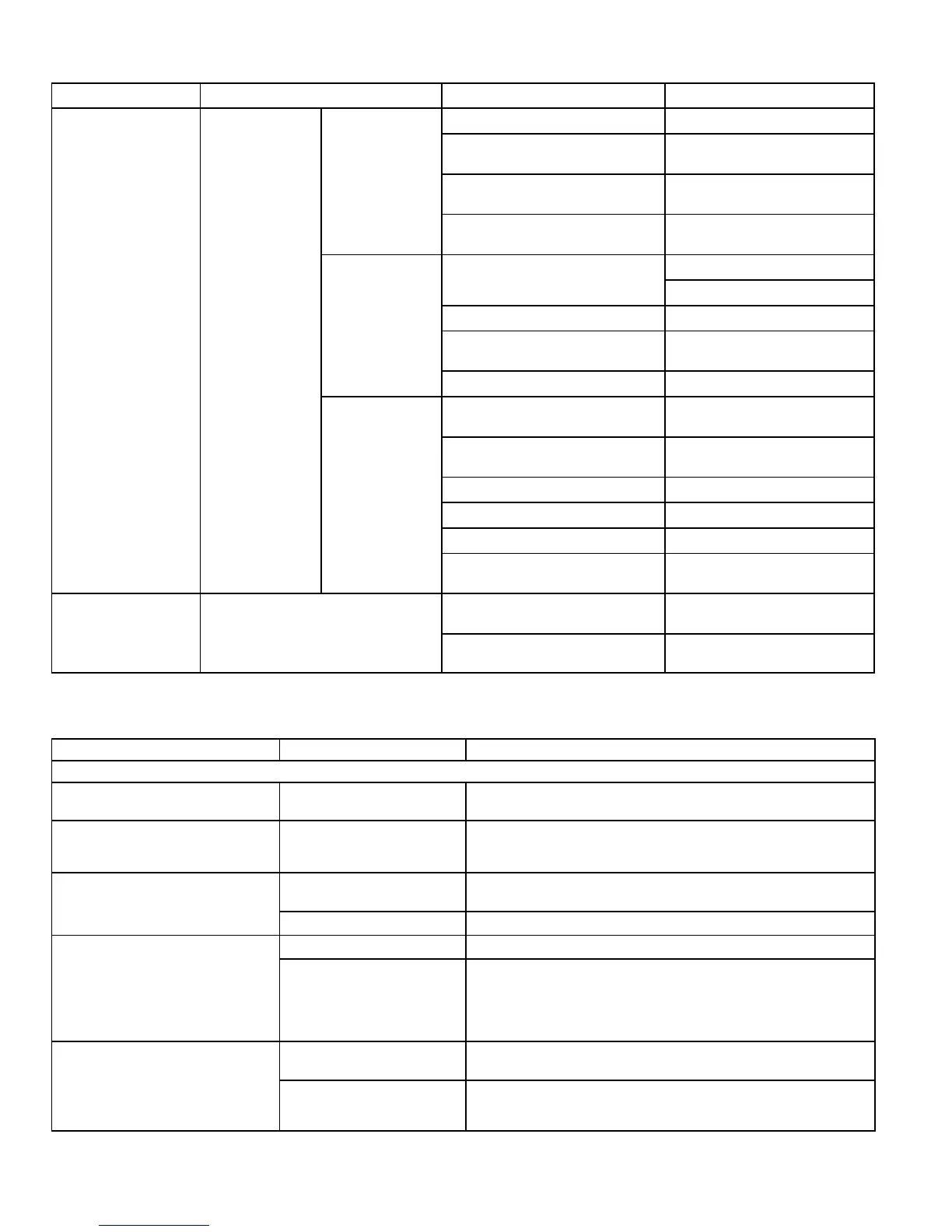

Troubelshooting O23 / OHR23 / OF23 −5 Units

Procedure Status Correction

CONDITION 1: BURNER DOES NOT ENERGIZE WITH A CALL FOR HEAT.

1.1 Check limit switch contacts are

closed and clean.

Clean contacts. Replace limit switch if necessary.

1.2 Check for line votage at oil pri

mary control. Voltage should be

120V

Check primary voltage source. Take appropiate measures to cor

rect if necessary.

1.3 Check LED light with burner off,

no call for heat (no flame)

LED is on

Cad cell or control is bad. Control sees external light or connections

are shorted. See step 1.4.

no ca

or

eat

no

ame

LED is off See step 1.5.

LED is off Eliminate exteranl light or shield light from cad cell

1.4 Sheild cad cell from external

light

LED stays on

Replace cad cell and recheck.

If LED stays on remove cad cell lead wires from burner control

and recheck.

If LED turns off, replace cad cell bracket assembly.

If LED stays on replace buner control

1.5 On warm air systems, Remove

one thermostat lead and jumper

Burner energizes

Trouble in thermostat or limit circuit. Check thermostat or limit wir

ing connections.

one t

ermostat

ea

an

umper

thermostat (T to T) terminals on

burner control.

Burner does not energize

Disconnect line voltage power and open line switch

Check all wiring and tighten any loose connections. Recheck

If burner does not energize replace burner control

Loading...

Loading...