Page 38

Charge Verification − Approach Method − AHRI Testing

1− Using the same thermometer, compare liquid tempera-

ture to outdoor ambient temperature.

Approach Temperature = Liquid temperature (at con-

denser outlet) minus ambient temperature.

2− Approach temperature should match values in table

11. An approach temperature greater than value

shown indicates an undercharge. An approach tem-

perature less than value shown indicates an over-

charge.

3− The approach method is not valid for grossly over or

undercharged systems. Use tables 5 through 10 as a

guide for typical operating pressures.

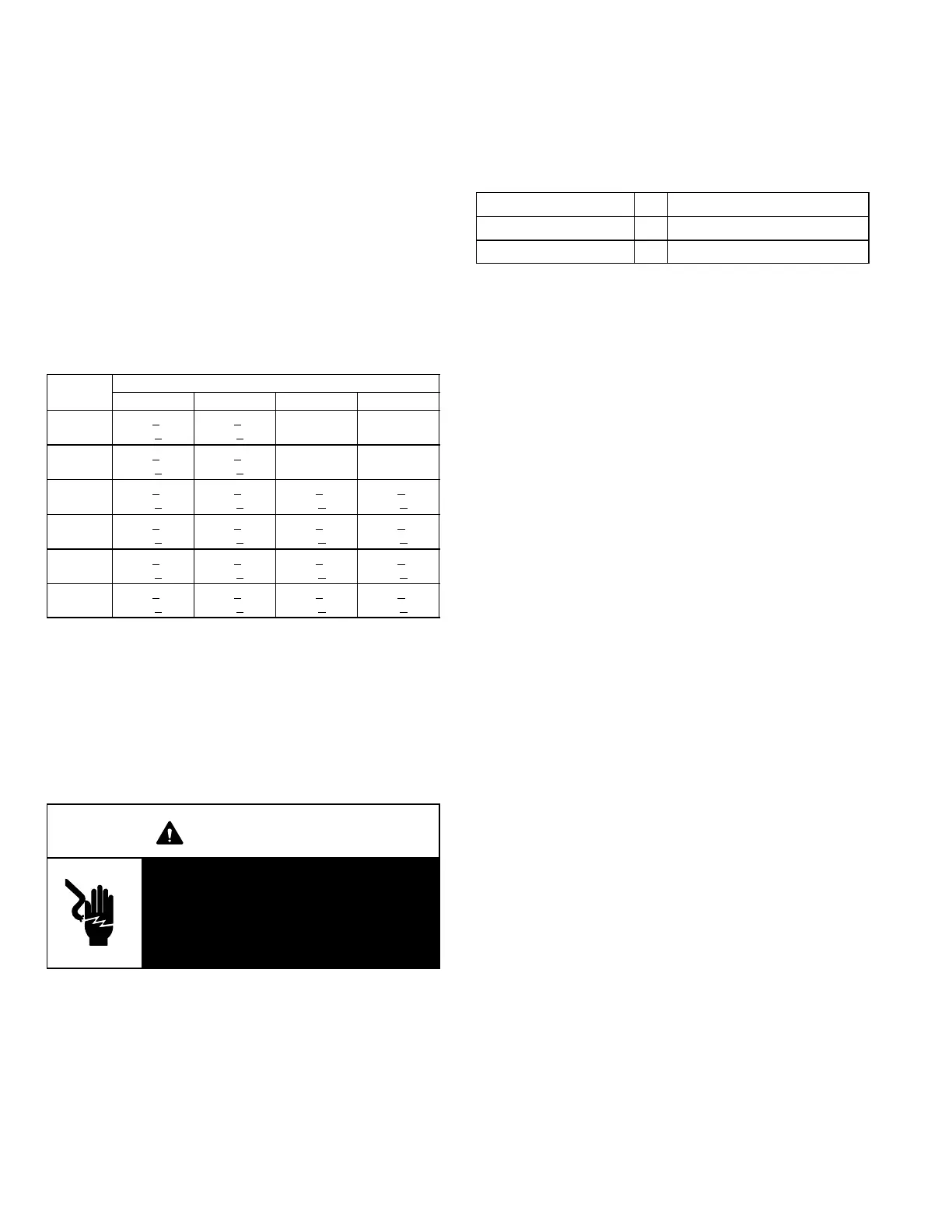

TABLE 11

APPROACH TEMPERATURES

L Series

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage 3rd Stage 4th Stage

120 CAV

8°F + 1

(4.4°C + 0.5)

6°F + 1

(3.3°C + 0.5)

NA NA

120

MSAVt

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

NA NA

240 CAV

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

240

MSAV

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

288 CAV

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

288

MSAV

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

6°F + 1

(3.3°C + 0.5)

IV− SYSTEMS SERVICE CHECKS

A−Cooling System Service Checks

SCA/SCB units are factory charged and require no further ad-

justment; however, charge should be checked periodically us-

ing the approach method. The approach method compares

actual liquid temperature with the outdoor ambient tempera-

ture. See section III−CHARGING.

V−MAINTENANCE

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon-

nect switch(es). Unit may have multiple

power supplies.

A−Filters

Units are equipped with filters as shown in table 12. Units

will accept 4" filters. Filters should be checked monthly and

replaced when necessary with filters of like kind and size.

Take note of air flow direction marking on filter frame when

reinstalling filters.

TABLE 12

SG/SC Unit

Qty Filter Size − inches (mm)

120 6 16 X 25 X 2 (406 X 635 X 51)

240/288 12 20 X 20 X 2 (508 X 508 X 51)

NOTE−Filters must be U.L.C. certified or equivalent for

use in Canada.

B−Lubrication

All motors and blower wheels used in SCA/SCB units

are prelubricated; no further lubrication is required.

C−Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove

access panel or to clean blower wheel.

D−Evaporator Coil

Inspect and clean coil at beginning of each season. Clean

using mild detergent or commercial coil cleanser. Check

condensate drain pan and line, if necessary. Flush coil and

condensate drain with water taking care not to get insula-

tion, filters and return air ducts wet. Check connecting

lines and coil for evidence of oil and refrigerant leaks.

E−Condenser Coil

Clean condenser coil annually with detergent or com-

mercial coil cleaner and inspect monthly during the cool-

ing season. Check connecting lines and coil for evidence

of oil and refrigerant leaks.

NOTE−If owner complains of insufficient cooling, the

units’ charge should be checked. Refer to Charging

sections in this manual.

F−Electrical

1− Check all wiring for loose connections.

2− Check for correct voltage at unit (unit operating).

3− Check amp−draw on both condenser fan motor and

blower motor.

Fan Motor Rating Plate ____ Actual ________

Indoor Blower Motor Rating Plate____ Actual____

Loading...

Loading...