6/2013 507163-01

*2P62013* *P507163-01*

Page 1

2013 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

IMPORTANT

This unit must be matched with an indoor coil as speci

fied in Lennox SSB*H4 Product Specification bulletin.

Coils previously charged with HCFC-22 must be

flushed.

NOTICE TO INSTALLER

UNIT PLACEMENT

It is critical for proper unit operation to place outdoor unit on an

elevated surface as described in Unit Placement section on page 7.

BRAZING LINE SET TO SERVICE VALVES

It is imperative to follow the brazing technique illustrated starting on

page 12 to avoid damaging the service valve's internal seals.

INSTALLATION

INSTRUCTIONS

S-CLASS SSB*H4 Units

AIR CONDITIONER UNITS

507163-01

6/2013

Supersedes 506641-01

TABLE OF CONTENTS

Shipping and Packing List 1......................

General 1......................................

Unit Dimensions 2...............................

Model Number Identification 2....................

Unit Parts Arrangement 3........................

Operating Gauge Set and Service Valves 4.........

Recovering Refrigerant from Existing System 6.....

New Unit Placement 7...........................

Removing and Installing Panels 9.................

New or Replacement Line Set 10...................

Brazing Connections 12...........................

Flushing Line Set and Indoor Coil 15................

Installing Indoor Metering Device 16................

Leak Test Line Set and Indoor Coil 17...............

Evacuating Line Set and Indoor Coil 18.............

Electrical 19.....................................

Servicing Units Delivered Void of Charge 21.........

Unit Start-Up 21.................................

System Refrigerant 22............................

System Operation 25.............................

Maintenance 26..................................

Checklists 27....................................

Shipping and Packing List

Check the unit for shipping damage and listed times below

are intact. If damaged, or if parts are missing, immediately

contact the last shipping carrier.

1 - Assembled outdoor unit.

General

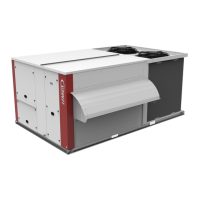

Two-stage S-Class SSB*H4 outdoor units use

HFC-410A refrigerant. This unit must be installed with a

matching indoor coil and line set as outlined in the Product

Specification bulletin. S-Class SSB*H4 outdoor units

are designed for use in expansion valve systems (TXV)

only. They are not designed to be used with other

refrigerant flow control devices. The Product Specification

bulletin lists a TXV kit that must be ordered separately.

Litho U.S.A.

Loading...

Loading...