Page 39

F- Proper Gas Flow (Approximate)

Furnace should operate at least 5 minutes before check-

ing gas ow. Determine time in seconds for two revolu-

tions of gas through the meter. (Two revolutions assures

a more accurate time.) Divide by two and compare to time

in TABLE 18 below. If manifold pressure matches TABLE

20 and rate is incorrect, check gas orices for proper size

and restriction.

NOTE- To obtain accurate reading, shut o all other gas

appliances connected to meter.

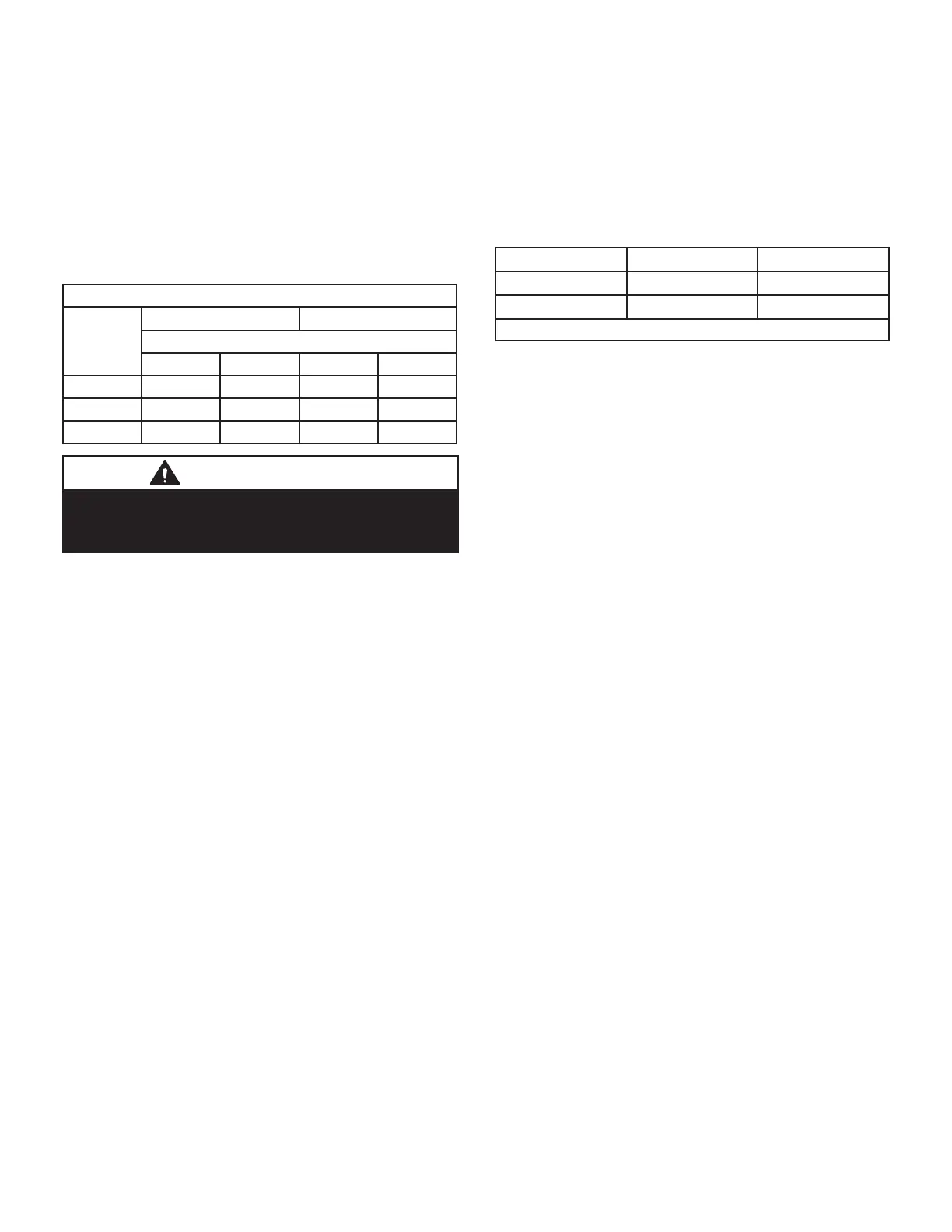

TABLE 18

GAS METERING CLOCKING CHART

SL280

Unit

Natural 1000 btu/cu ft LP 2500 btu cu/cu ft

Seconds For One Revolution

1 cu ft dial 2 cu fr dial 1 cu ft Dial 2 cu ft Dial

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

IMPORTANT

.For safety, shut unit o and remove manometer as soon

as an accurate reading has been obtained. Take care to

replace pressure tap plug.

G- Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking com-

bustion.

See sections E- and F-. Take combustion sample beyond

the ue outlet and compare to the table below. The max-

imum carbon monoxide reading should not exceed 100

ppm.

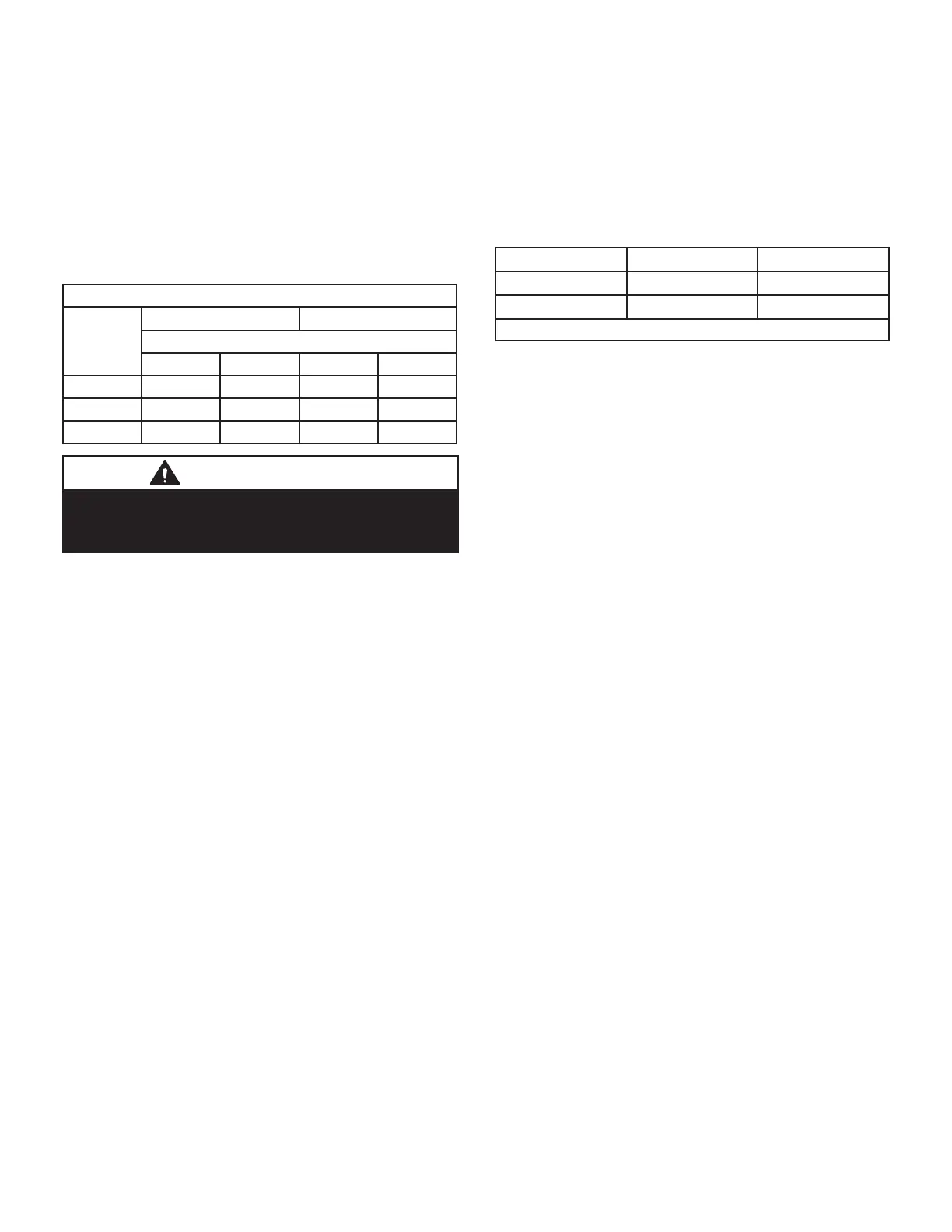

TABLE 19

Firing Rate CO2% For Nat CO2% For L.P.

High Fire 6.0 - 7.4 6.9 - 8.4

Low Fire 4.8 - 6.0 5.7 - 7.0

The carbon monoxide reading should not exceed 100 ppm.

H-High Altitude

The manifold pressure, gas orice and pressure switch

may require adjustment or replacement to ensure proper

operation at higher altitudes. See TABLE 20 for manifold

pressures, TABLE 21 for pressure switch kits and TABLE

22 or TABLE 23 for gas conversion kits.

Loading...

Loading...