Page 59

G- Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking com-

bustion. Take combustion sample beyond the ue outlet

and compare to the tables below.

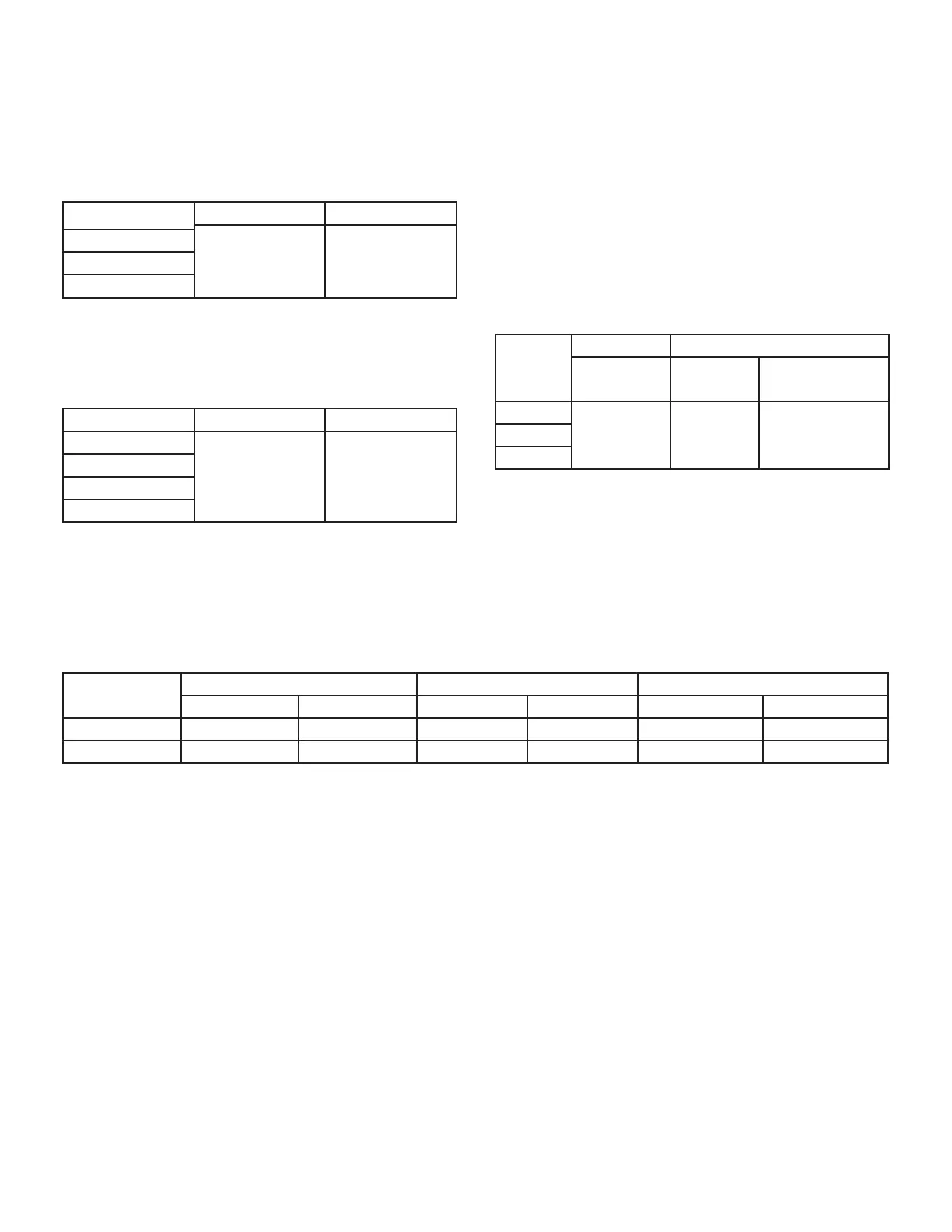

TABLE 30

High Fire

SLP99DFV Unit

CO

2

% Nat CO

2

L.P.

6.5 - 9.0 7.7 - 10.2

070

090

110

The maximum carbon monoxide reading should not ex-

ceed 100 ppm.

TABLE 31

Low Fire

CO

2

% Nat CO

2

% LP

SLP99DFV Unit

4.7 - 7.2 5.7 - 8.2

070

090

110

The maximum carbon monoxide reading should not ex-

ceed 100 ppm.

H- High Altitude

NOTE - In Canada, certication for installations at eleva-

tions over 4500 feet (1372 m) is the jurisdiction of local

authorities.

Units require no manifold pressure adjustment nor a gas

orice change for operation at altitudes up to 10,000 feet

(3048m) above sea level. Units installed at altitude of

7,501 to 10,000 feet (2287 to 3048m) require a pressure

switch change per TABLE 32. TABLE 32 also lists gas

conversion kit requirements at all altitudes.

The combustion air pressure switch is factory-set and re-

quires no adjustment.

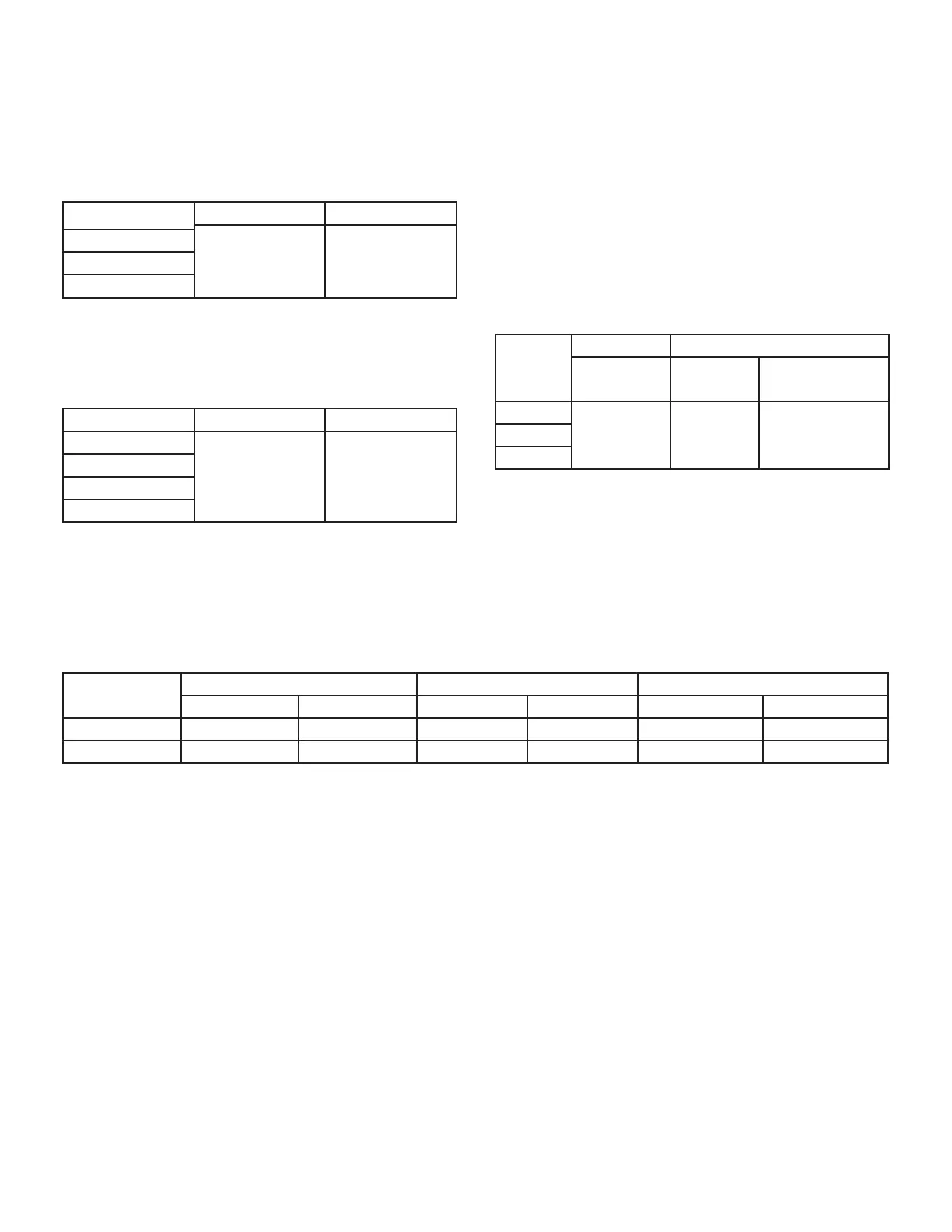

TABLE 32

Conversion Kit Requirements

Model

Input Size

LP/Propane High Altitude Pressure Switch

0 - 10,000 ft

(0 - 3048m)

0 - 7500 ft

(0 - 2286m)

7501 ft - 10,000 ft

(287 - 3048m)

070

65W77

Not

Required

14T67090

110

TABLE 33

Manifold and Operating Signal Pressures in inches 0 - 7500 ft (0 - 2286 m)

SLP99 Firing

Rate

Manifold Pressure Natural Gas Manifold Pressure LP/Propane Operating Pressure Signal (Delta P)

Min Max Min Max Min Max

Low 0.4 0.95 1.2 2.8 0.20 0.40

High 3.0 3.8 9.1 10.5 0.95 1.25

NOTE - A natural to LP/propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit instal-

lation instruction for the conversion procedure.

NOTE - The values given in table are measurements only. The gas valve should NOT be adjusted.

Loading...

Loading...