Page 25

SSB*H4 SERIES

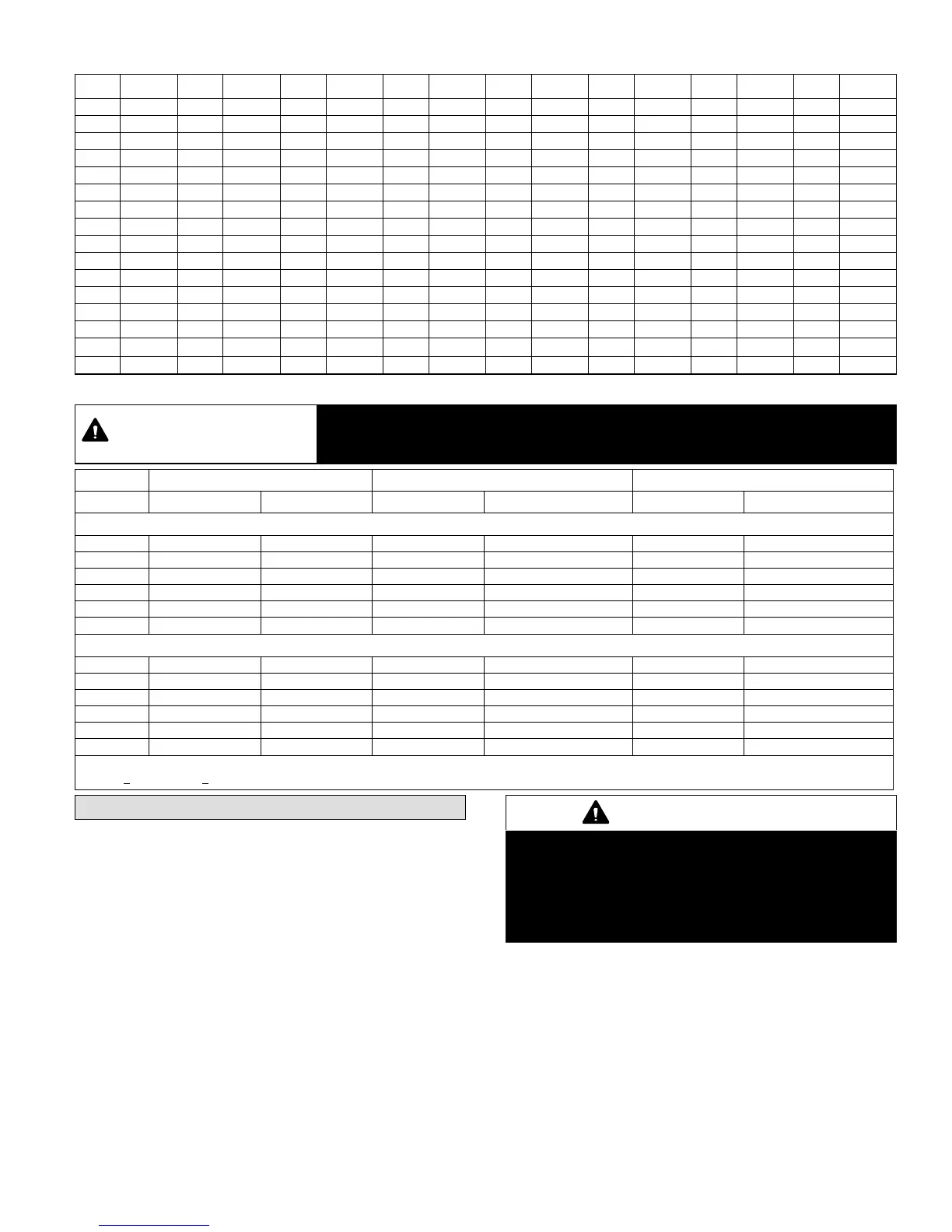

Table 3. HFC-410A Temperature (°F) - Pressure (Psig)

°F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig

32 100.8 48 137.1 63 178.5 79 231.6 94 290.8 110 365.0 125 445.9 141 545.6

33 102.9 49 139.6 64 181.6 80 235.3 95 295.1 111 370.0 126 451.8 142 552.3

34 105.0 50 142.2 65 184.3 81 239.0 96 299.4 112 375.1 127 457.6 143 559.1

35 107.1 51 144.8 66 187.7 82 242.7 97 303.8 113 380.2 128 463.5 144 565.9

36 109.2 52 147.4 67 190.9 83 246.5 98 308.2 114 385.4 129 469.5 145 572.8

37 111.4 53 150.1 68 194.1 84 250.3 99 312.7 115 390.7 130 475.6 146 579.8

38 113.6 54 152.8 69 197.3 85 254.1 100 317.2 116 396.0 131 481.6 147 586.8

39 115.8 55 155.5 70 200.6 86 258.0 101 321.8 117 401.3 132 487.8 148 593.8

40 118.0 56 158.2 71 203.9 87 262.0 102 326.4 118 406.7 133 494.0 149 601.0

41 120.3 57 161.0 72 207.2 88 266.0 103 331.0 119 412.2 134 500.2 150 608.1

42 122.6 58 163.9 73 210.6 89 270.0 104 335.7 120 417.7 135 506.5 151 615.4

43 125.0 59 166.7 74 214.0 90 274.1 105 340.5 121 423.2 136 512.9 152 622.7

44 127.3 60 169.6 75 217.4 91 278.2 106 345.3 122 428.8 137 519.3 153 630.1

45 129.7 61 172.6 76 220.9 92 282.3 107 350.1 123 434.5 138 525.8 154 637.5

46 132.2 62 175.4 77 224.4 93 286.5 108 355.0 124 440.2 139 532.4 155 645.0

47 134.6 78 228.0 109 360.0 140 539.0

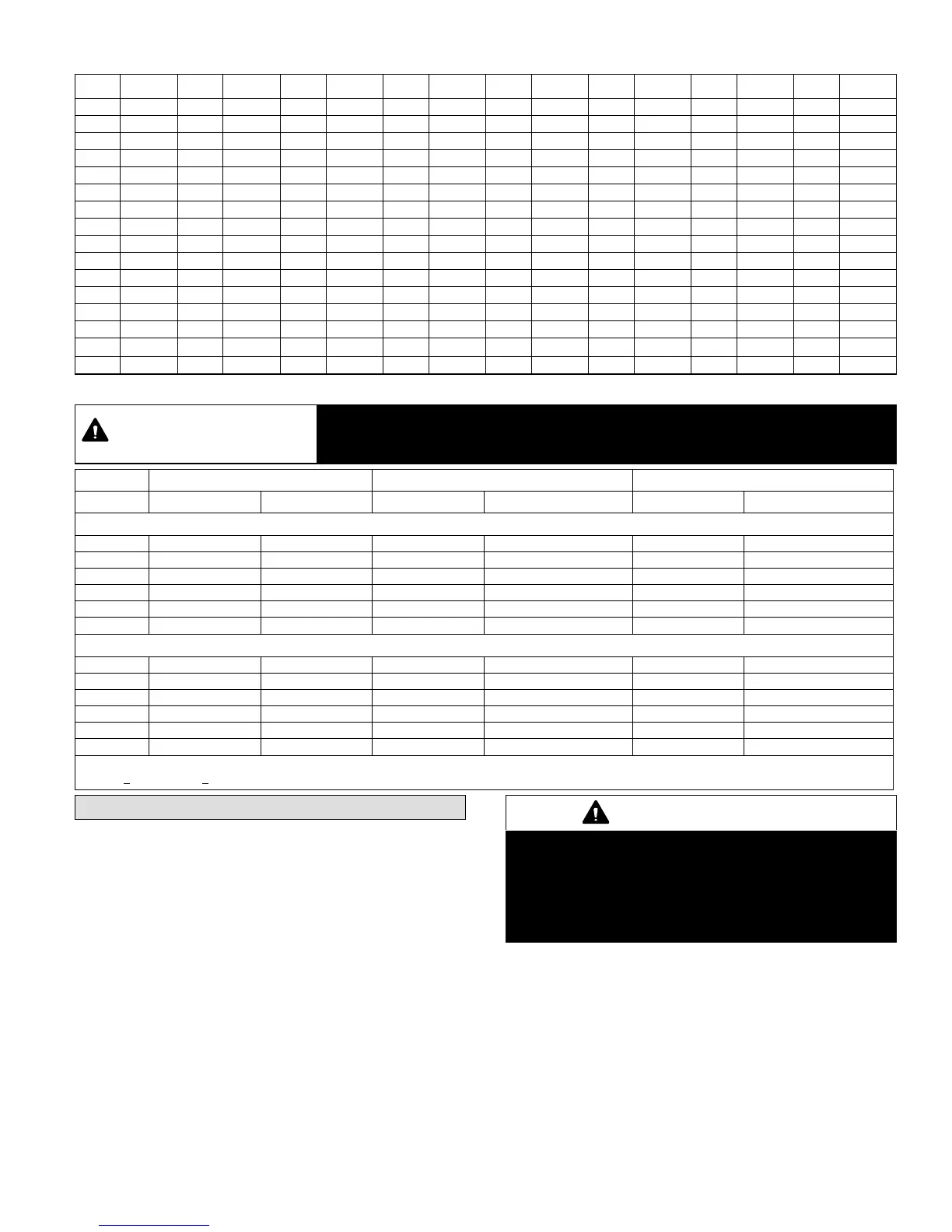

Table 4. Normal Operating Pressures (Liquid +10 and Suction +5 psig)

IMPORTANT

Use this table to perform maintenance checks; it is not a procedure for charging the system. Minor variations

in these pressures may be due to differences in installations. Significant deviations could mean that the

system is not properly charged or that a problem exists with some component in the system.

Model SSB036H4S4 SSB048H4S4 SSB060H4S4

5F (5C)*

Liquid Suction Liquid Suction Liquid Suction

First Stage (Low Capacity)

65 (18) 217 141 229 140 229 134

75 (24) 251 143 263 143 264 138

85 (29) 292 146 304 146 305 140

95 (35) 337 147 350 148 349 142

105 (41) 387 150 400 150 402 147

115 (46) 440 154 453 155 455 149

Second Stage (High Capacity)

65 (18) 230 137 234 135 244 129

75 (24) 265 140 269 137 282 131

85 (29) 307 141 312 140 324 133

95 (35) 354 144 359 141 371 136

105 (41) 405 146 409 143 422 139

115 (46) 460 149 465 146 474 143

*Temperature of air entering outdoor coil.

**(Liquid +10 psig; Vapor +5 psig) Typical pressures; indoor unit match up, indoor air quality equipment, and indoor load will cause the pressures to vary.

System Operation

SECOND-STAGE OPERATION

If the demand defrost control (A108) receives a call for

second-stage compressor operation Y2 in heating or

cooling mode and the first‐stage compressor output is

active, the second‐stage compressor solenoid output will

be energized.

If first‐stage compressor output is active in heating mode

and the outdoor ambient temperature is below the selected

compressor lock-in temperature, the second‐stage

compressor solenoid output will be energized without the

Y2 input. If the jumper is not connected to one of the

temperature selection pins on P3 (40, 45, 50, 55°F), the

default lock-in temperature of 40°F (4.5°C) will be used.

IMPORTANT

Some scroll compressor have internal vacuum protector

that will unload scrolls when suction pressure goes

below 20 psig. A hissing sound will be heard when the

compressor is running unloaded. Protector will reset

when low pressure in system is raised above 40 psig. DO

NOT REPLACE COMPRESSOR.

Loading...

Loading...