Parameter setting with the XT EMZ9371BC keypad

Vector control

8

Commissioning

8.5

8.5.2

L

8.5-4

EDS82EV903-1.0-11/2002

Switch-on sequence Note

15. Activate the motor te mperat ure monitoring (C0119), if a PTC or

thermal contact is connected to the terminal X2.2

Lenze setting: switched-off

Setting possibilities: (¶ 8.6-5)

16. Setpoint selection e. g. via potentiometer at the

terminals7,8,9

17. Enable the controller.

20

28

X3

misc002

Terminal X3/28 = HIGH

18. The drive should be running now CW rotation: X3/E4 = LOW

CCW rotation: X3/E4 = HIGH

If the drive does not start, press U

)

))

) Note!

In the menu ”Diagnostic” the most important drive parameters

canbemonitored

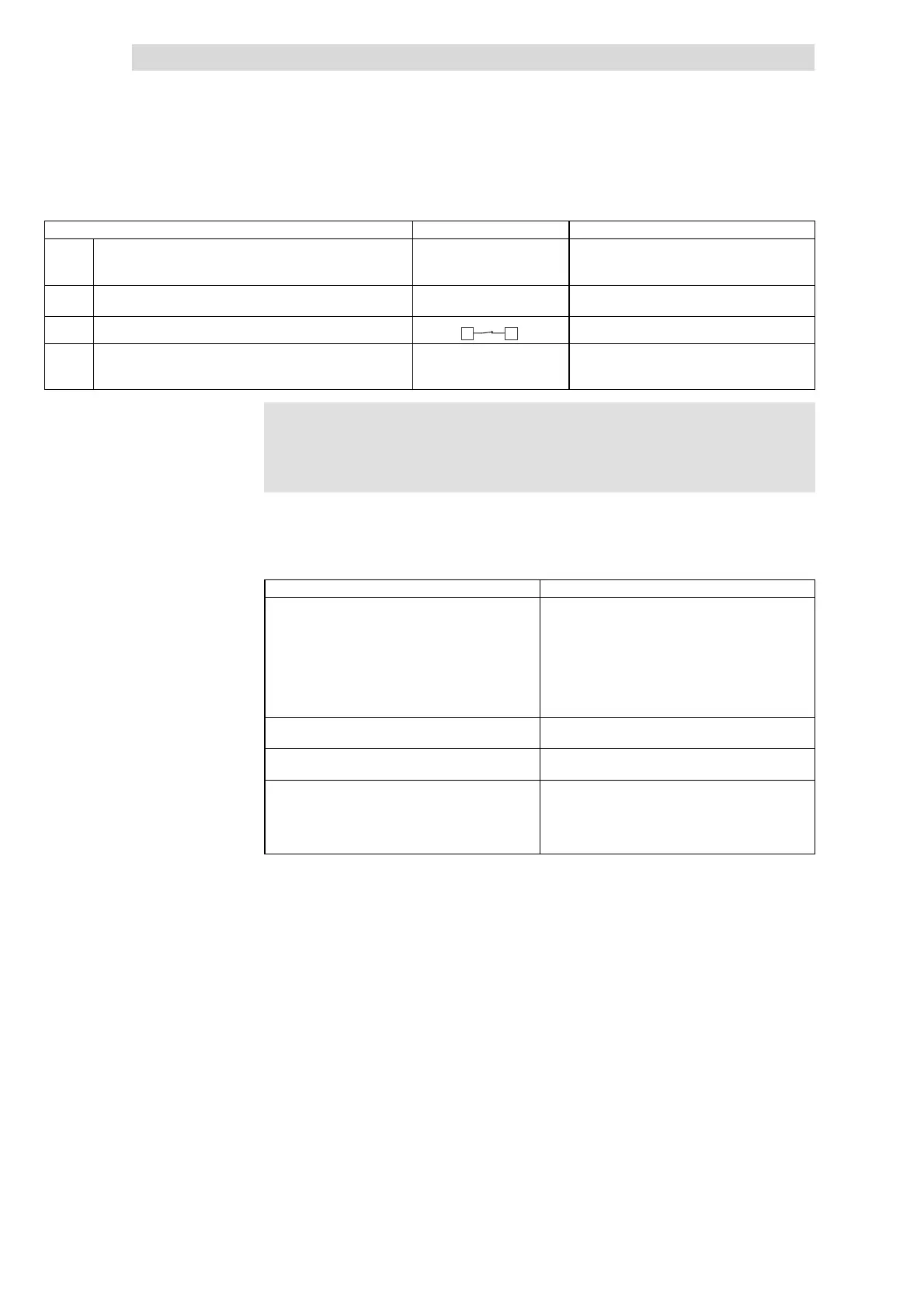

In general, the vector control is ready for operation after the motor parameters

have been identified. Vector control must only be optimised for the following drive

performance: 33

Drive performance Remedy

Rough motor run and motor current (C0054) > 60 %

rated motor current in idle running (stationary operation)

1. Reduction of motor inductance (C0092) by 10 %

2. Check of motor current under C0054

3. If the motor current (C0054) > 50 % of the rated

motor current:

– C0092 must be reduced until the mot or current

amounts to 50 % of the rated motor current

– Reduce C0092 by max. 20 %!

– Note: If you reduce C0092 the t o rque will decrease!

Torque too low for frequencies f < 5 Hz (starting torque) Increase of motor resistance (C0084) or increase of

motor inductance (C0092)

Poor constant speed at high loads (setpoint and motor

speed are not proportional).

Increase o f slip compensa t i on (C0021)

Overcompensation results in drive instability!

Error messages OC1, OC3, OC4 or OC5 during

acceleration times (C0012) < 1 s (drive controller is no

longer able to follow the dynamic processes)

Change readjustment time of the I

max

controller (C0078):

• Reduction o f C0078 = I

max

controller becomes quicker

(more dynamic)

• Increase of C0078 = I

max

controller becomes slower

(”smoother”)

Optimising the vector control

Loading...

Loading...