Electrical installation

Wiring

Design of the cables

4

42

EDK94ZPM113 DE/EN/FR/ES/IT 1.0

4.3.2 Design of the cables

ƒ The cables used must comply with the approvals required for the location

(e.g. UL).

ƒ It is imperative to comply with the regulations concerning minimum

cross-sections of PE conductors. The cross-section of the PE conductor

must be at least as large as the cross-section of the power connections.

ƒ The effectiveness of a shielded cable is reached by:

– Providing a good shield connection through large-surface s hield

contact.

– Using only braided shields with low shield resistance made of tin-plated

or nickel-plated copper b raid.

– Using braided shields with an overlap rate > 70 % and an overlap angle

of 90 °.

– Keeping unshielded cable ends as short as possible.

Use system cables or shielded cables for these connections:

ƒ Motor

ƒ Motor holding brake (connected to optional motor brake control)

ƒ Motor temperature monitoring

The f ollowing connections need not be shielded:

ƒ DC bus

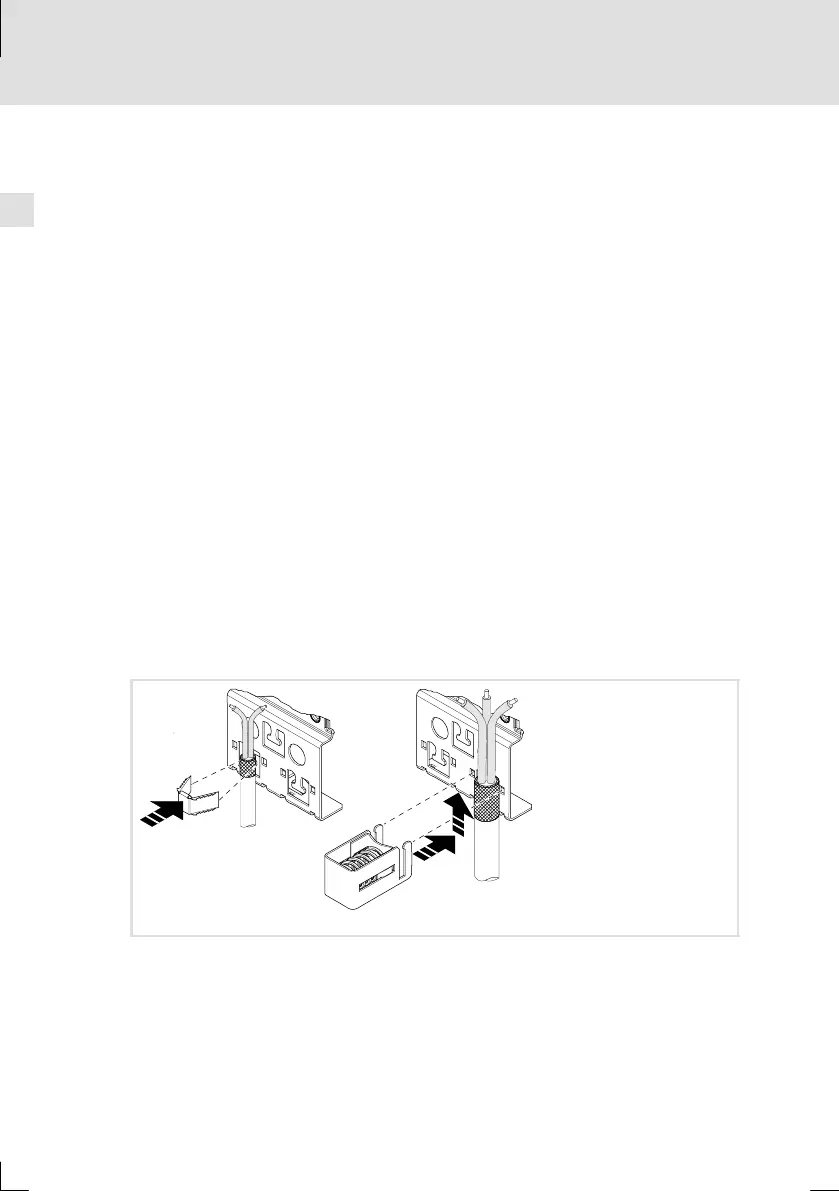

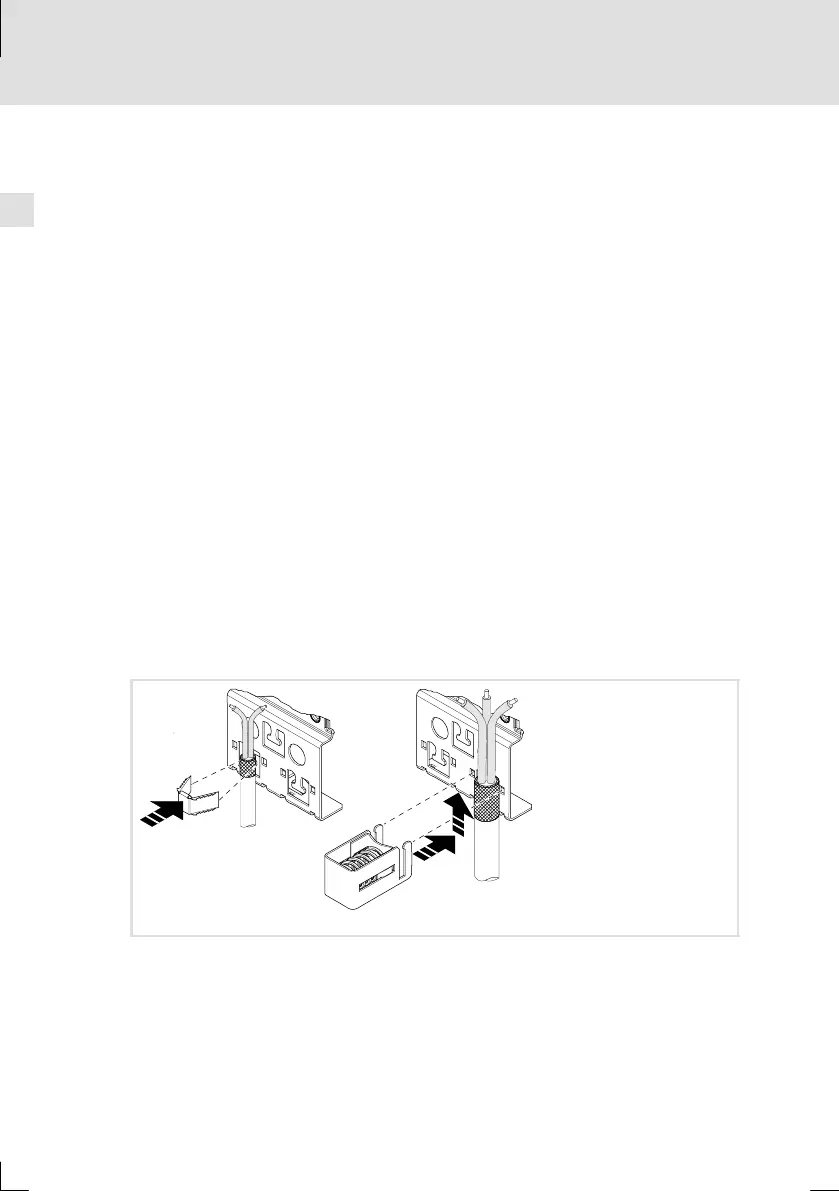

4.3.3 How to connect the shield

E94AZPS004

Fig.7-3 Connect the shield to the shield sheet (graphics on the right: motor cable for device sizes

II and III)

Loading...

Loading...