Troubleshooting and fault elimination

Error messages

1

l

EDKVF9333 EN 1.0

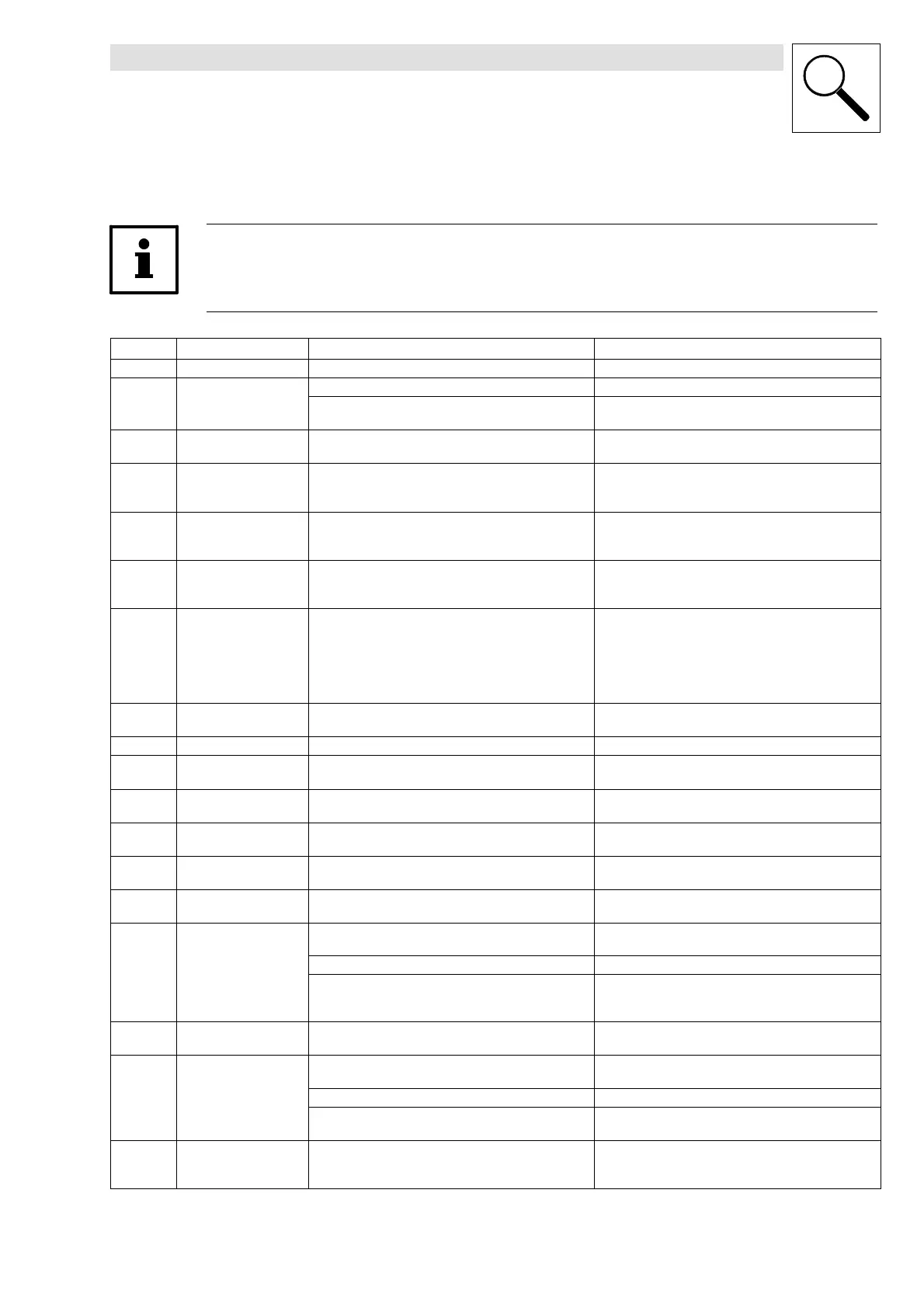

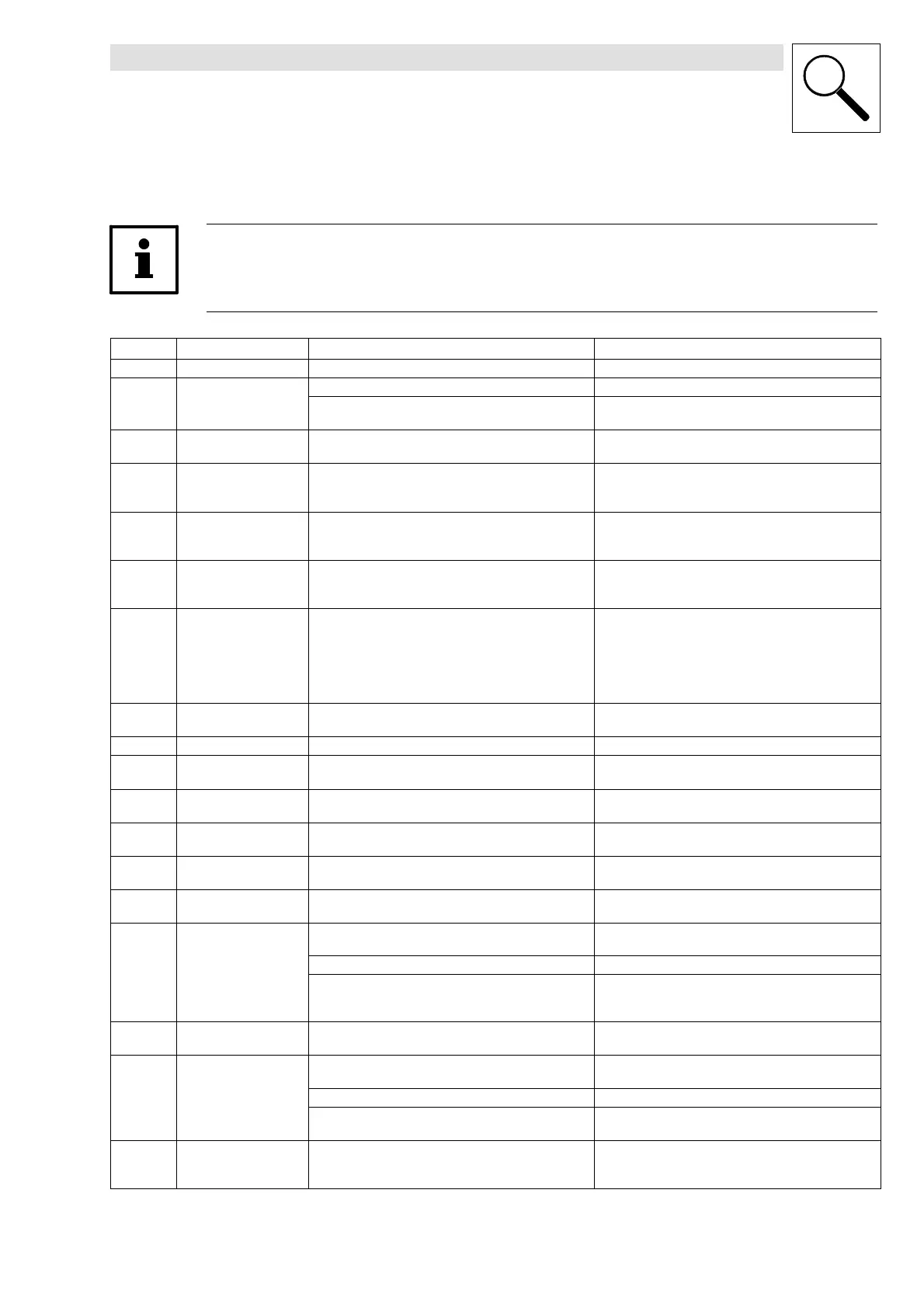

3.3 Error messages

Tip!

If you use GDC or a fieldbus module to find out about a n error (C0168/x), the error message will be

represented by an error number.

Display Error Cause Remedy

--- No error - -

CCr System fault Strong interferences on control cables Screen the control cables

Ground or earth loops in the wiring Ensure PE wiring complies with EMC requirements (

LEERER MERKER )

CE0 Communication error Error during the transfer of control c ommands via the

automation interface X1

Plug in the automation module firmly and, if necessary, bolt

it down

CE1 Communication error at

the process data input

object CAN_IN_1

CAN_IN_1 object receives faulty data, or communication is

interrupted

Check cable at X4

Check transmitter

Increase monitoring time under C0357/1 if necessary

CE2 Communication error at

the process data input

object CAN_IN_2

CAN_IN_2 object receives faulty data, or communication is

interrupted

Check cable at X4

Check transmitter

Increase monitoring time under C0357/2 if necessary

CE3 Communication error at

the process data input

object CAN_IN_3

CAN_IN_3 object receives faulty data, or communication is

interrupted

Check cable at X4

Check transmitter

Increase monitoring time under C0357/3 if necessary

CE4 BUS-OFF state Controller has received too many incorrect telegrams via

system bus X4 and has disconnected from the bus

Check wiring

Check bus termination (if any)

Check screen contact of the cables

Check PE c onnection

Check bus load:

Reduce baud rate (observe cable length)

EEr External fault (TRIP-Set) A digital input assigned to the TRIP set function has been

activated

Check external encoder

H05 Internal error Contact Lenze

H07 Incorrect power stage During initialization of the controller, an incorrect power

stage was detected

Contact Lenze

H10 Sensor fault: heat sink

temperature

Sensor of the heat sink temperature detection indica tes

undefined values

Contact Lenze

H11 Sensor fault indoor

temperature

Sensor of indoor temperature detection indic ates undefined

values

Contact Lenze

ID1 Fault during motor

identification

Measuring of the characteristic failed

Motor too small (P

motor

% P

controller

)

Check motor cable

Select bigger motor

ID2 Fault during motor

identification

No identification of the motor parameters Enter data of the nameplate of the connected motor

LP1 Motor phase failure

A current-carrying motor phase has failed Check motor;

Check supply module

The current limit is set too low Set a higher current limit under C0599

This monitoring is not suitable for:

•

Synchronous servo motors

•

for rotating-field frequencies > 480 Hz

Deactivate monitoring with C0597= 3

LU Undervoltage DC bus voltage is smaller than the value fixed under C0173 Check mains voltage

Check supply cable

r

MAX

Max. plant speed

exceeded (C0596)

Active load too high (e.g. for hoists) Check drive dimensioni ng

Drive is not speed-controlled, torque excessively limited Increase torque limit

The current speed has been detected incorrectly. Check encoder selection (C0025)

Check motor da ta

OC1 Short-circuit Short-circuit

Excessive capacitive charging current in the motor cable

Find out cause of short-circuit; check cable

Use motor cable which is shorter or has a lower

capacitance

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - e.mail: info@ctiautomation.net

Loading...

Loading...