Commissioning

5-6

SHB9300CRV EN 2.0

5.5.2 Adapt controller to the motor

To achieve an optimum speed-torque characteristic for the drive, it is necessary to enter the

nameplate data of the connected motor.

With Lenze motors:

Field Command Function

3 Click ”motor type (A)”. Select connected motor.

4 Click ”encoder (B)”. Selected feedback system used.

5 Click ”master value”. Setting of the master-value incremental encoder

For motors with a resolver, use the eight-digit designation of the motor nameplate ”encoder” (as an

option).

l

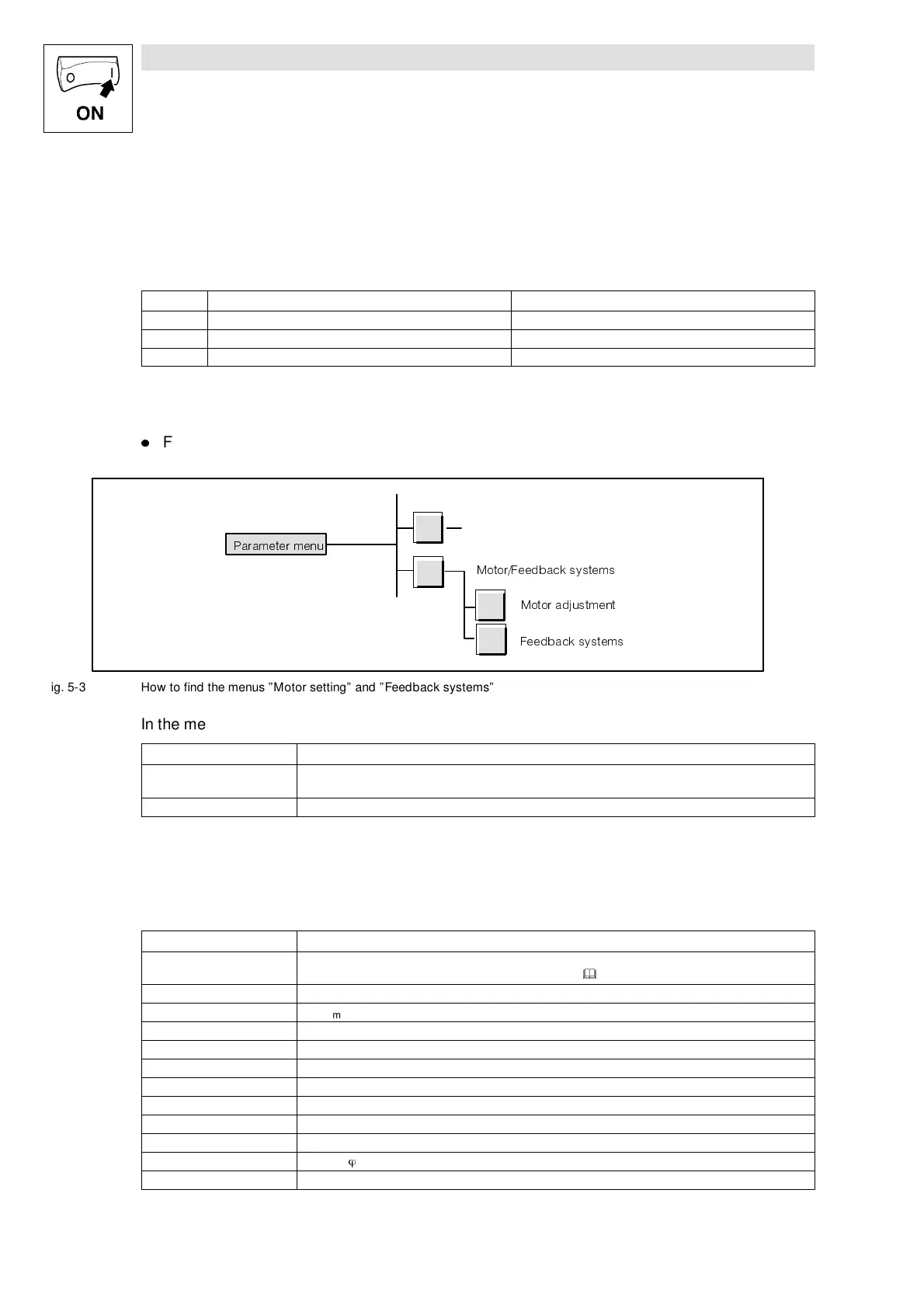

For this change to the parameter menu (see button Fig. 5-3) and select the menu

”Motor/feedback system”.

3DUDPHWHU PHQX

0RWRU)HHGEDFN V\VWHPV

0RWRU DGMXVWPHQW

)HHGEDFN V\VWHPV

Fig. 5-3 How to find the menus ”Motor setting” and ”Feedback systems”

In the menu ”Feedback systems”:

Command Function

Select C0416 Resolver fa ult

Enter value from the motor nameplate

Select C0003 Save data (C0003 = 1).

If you use a motor other than from Lenze:

Change to the menu ”Motor setting” (see Fig. 5-3).

In the menu ”motor setting”:

Command Function

Select C0086 Select a motor which best matches the motor used.

A list of available motors can be obtained from chapter 7.11

(

&

7-327)

.

Select C0006 Operating mode of the motor control

Select C0022 Apapt I

max

to the maximum motor current.

Select C0081 Rated motor power

Select C0084 Stator resistance of the motor (only for very high demands on the control characteristics).

Select C0085 Leakage inductance of the motor (only for very high demands on the control characteristics).

Select C0087 Rated motor speed

Select C0088 Rated motor current

Select C0089 Rated motor frequency

Select C0090 Rated motor voltage

Select C0091 Motor cos

j

.

Select C0003 Save data (C0003 = 1).

Loading...

Loading...