2 4 . 0

V

+

-

24VDC POWER SUPPLY

DIGITA

L MULTIMETER

100 SERIES SENSORS

Note: Use caution when sealing the cable at the top of the tank. There is a

ventilation/reference tube located within the cable. The purpose of this tube is

provide a comparison between atmospheric pressure and the pressure that is being

exerted on the sensing diaphragm within the tank. The reference tube must be open

and free to allow air to flow back to the pressure diaphragm. Avoid blocking or

bending the ventilation tube by compressing the cable. Always keep the cable

termination clean, dry and free of moisture and prevent liquid from entering the vent

tube. The LP100 Installation Junction Box comes with a Gortex breather to allow for

air to pass but not moisture. It also has the cable grip located at the bottom to

secure the sensor.

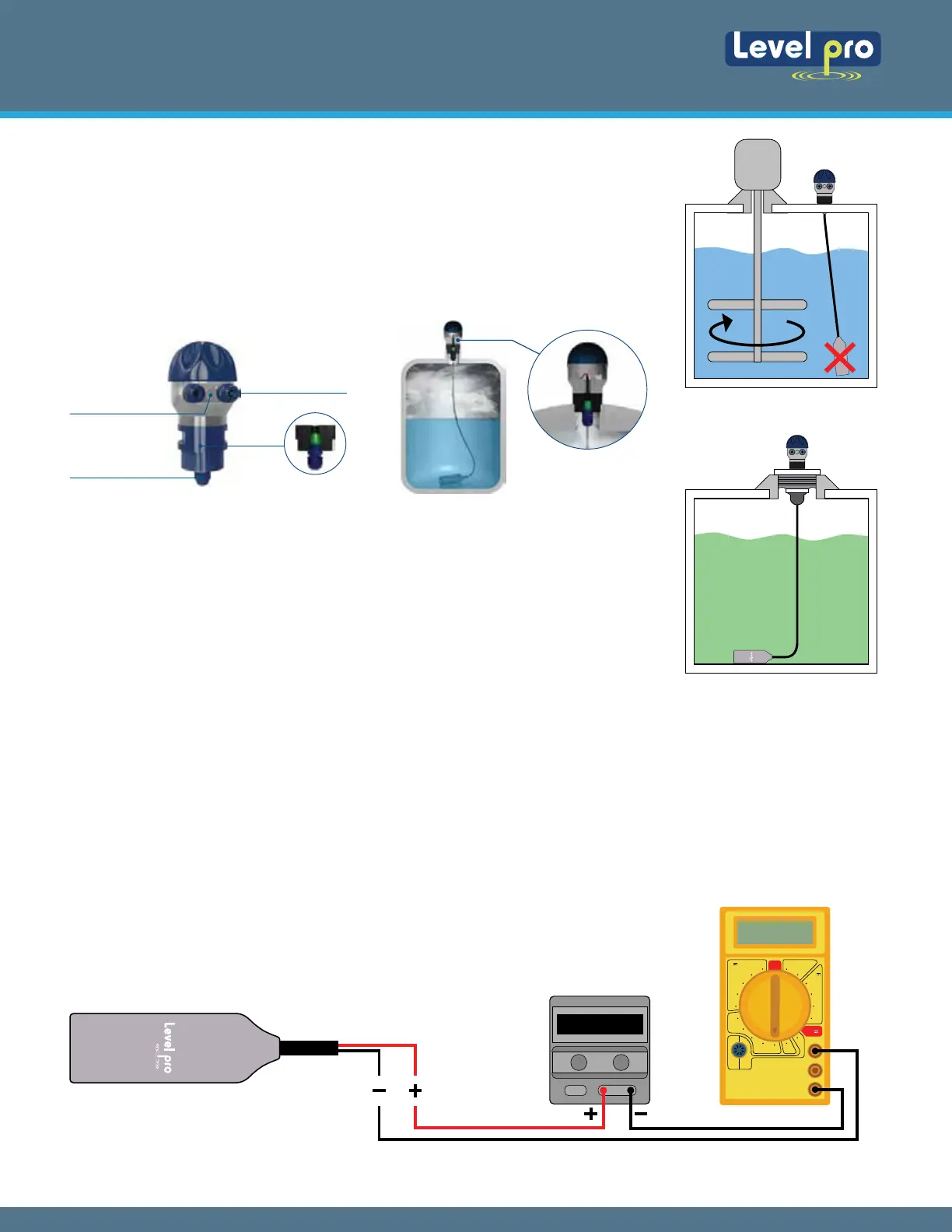

Avoid installations where other tank requirements will cause the transmitter to move or swing.

Example: A mixer blade could cause the level transmitter to whip around within the tank. An

alternative would be to move the transmitter to a more stable section of the tank or to install the

Transmitter inside a still well/drop tube. This will minimize the effects created by the mixer.

Termination: The cable for the transmitter is typically terminated at a junction box located on top of

the tank. Since the vent tube is contained within the cable, the pressure within the junction box

must always be the same as the reference (typically atmospheric) pressure for the liquid. The

inside of the function box must be clean, dry and free of moisture. (A descant can be provided)

Add the optional fitting LP 100 to complete the package. The LP 100 features a 2" NPT thread for

mounting and a liquid tight connector to seal the cable interface, and a Gortex breather that allows

for the transfer of air, but not moisture.

After final installation of the Levelpro transmitter and its companion receiver (TruVu), no routine maintenance is required. A

periodic check

of

system calibration is suggested. Be sure to include a brief description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before shipping.

Maintenance s

hould consist of inspection to see that the transmitter is free from debris and not coated with any substance, which would

prevent liquid from freely entering and leaving the transmitter. If this occurs, the transmitter should be cleaned.

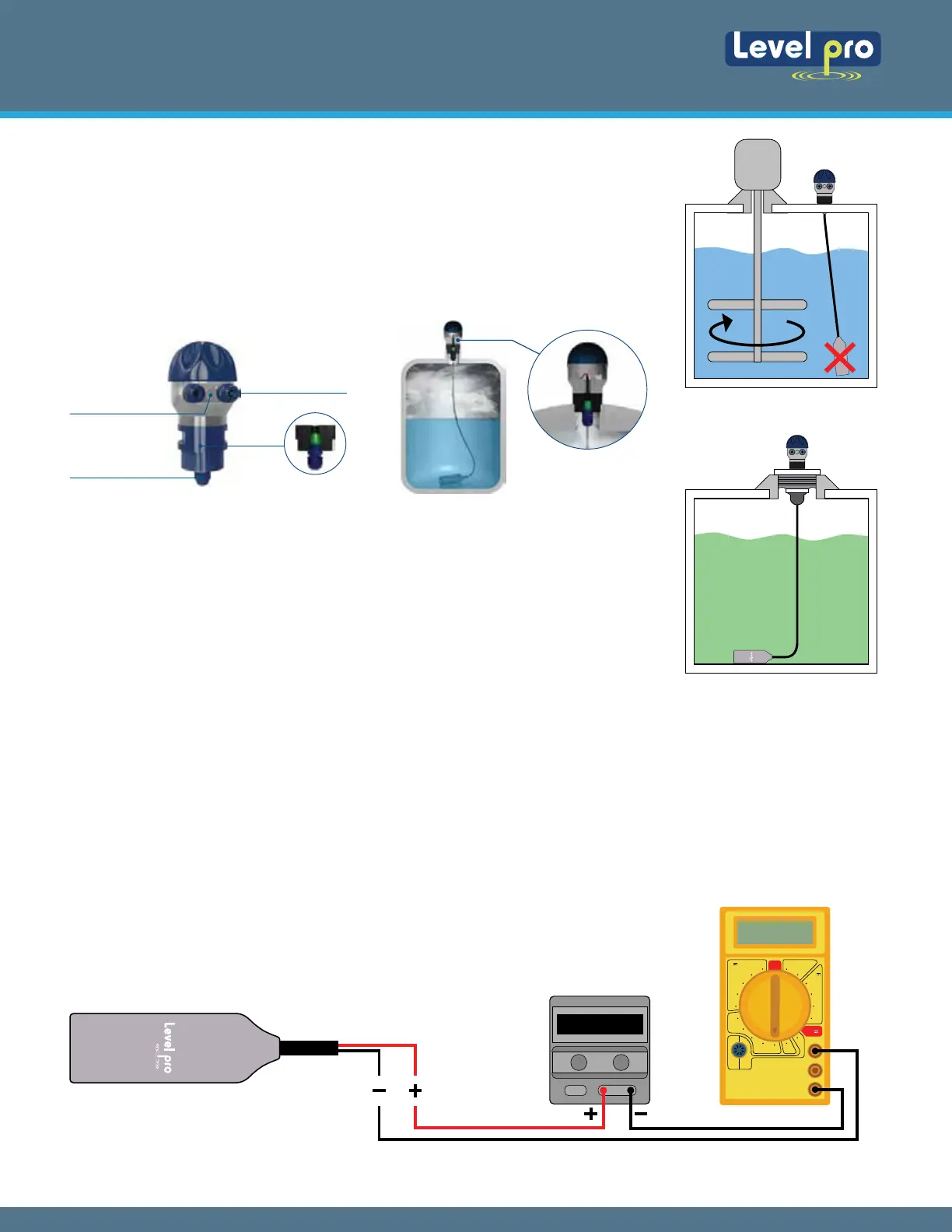

If transmitter is not functioning properly, isolate the transmitter from

the system and wire as shown below. Be sure to remove the sensor

from the classified area when preforming this test. Multi - Meter

should read 4mA with the transmitter out of liquid.

1. First, verify that the sensor is wired correctly.

2. Next, check if the power supply is providing the required power.

3. Finally confirm that the loop resistance is not exceeding the sensor's specification.

10. MAINTENANCE

Testing the Transmitter:

200

2000k

200k

E

B

C

C

B

E

E

NPN

PNP

E

20k

2000

200

hFE

2000

20

200

200

750

200

2000

20

200

1000

m

m

V

V

~

10A

OFF

4.0

24V

4mA

4-20mA Output

Cable Grip

Gortex Breather

Continuous Submersible Level Transmitter

Levelpro-Sensors Manual

09

Vaporbloc

®

Com

mA

Loading...

Loading...