12

6- Servicing your thruster

7- Specifications

At the annual boat service:

Remove any debris from tunnel, propeller and hub.

If the propeller is damaged or heavily contaminated,

replace it, best to be safe.

Apply grease to exposed thruster seal and shaft.

If hub is removed the tunnel gasket must be

replaced.

Inspect motor, ensure all leads are still tight.

Check all bolts and nuts are to correct torque.

Check the motor assembly is dry and that the

compartment is water tight.

Check and clean out thruster compartment.

Electric:

Inspect electric motor, ensure all leads are still

tight.

Brush out carbon dust from top of electric motor

especially on aluminium boats. Recommend

qualified electrician.

Propeller: Single 5 blade

Suitable fuse holder:

Standard - 589006 or T2- 589013

Thrusters are more likely to attract ‘debris’, so it is necessary to regularly check the tunnel.

6.1 Service schedule

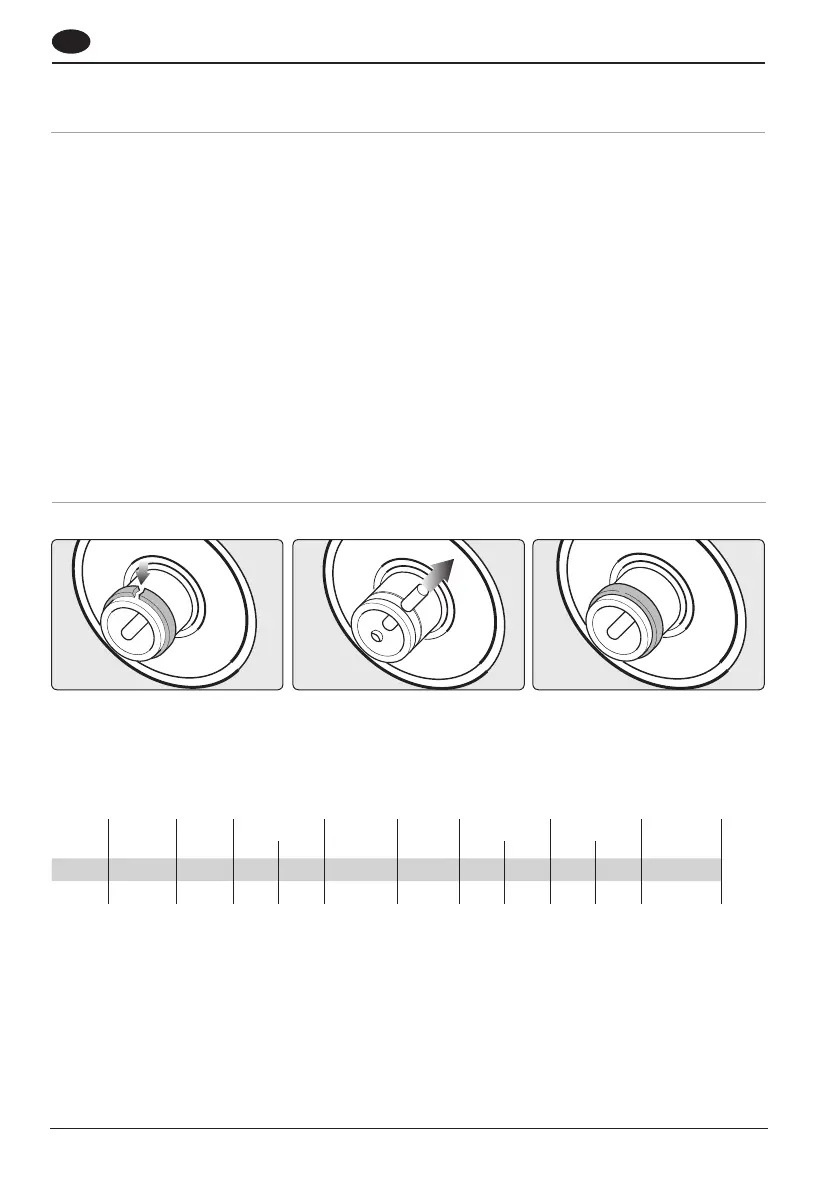

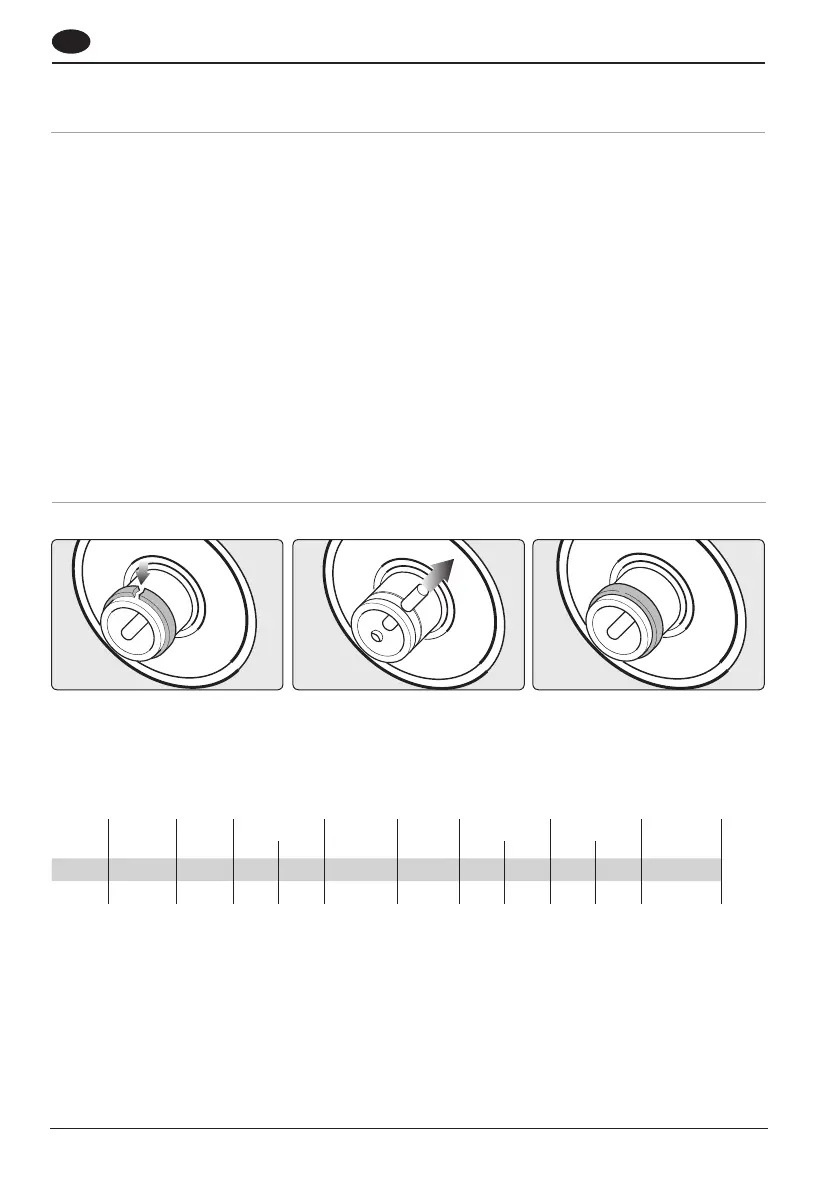

6.2 Changing drive pin

Cut cable tie on sha (if fitted) Tap in new pin and secure with new

plastic cable tie

Punch out pin parts

PART NO MODEL VOLTAGE POWER

GEARBOX

MATERIAL

TUNNEL THRUST WEIGHT FUSE

V kW hp (mm) kgf lbs Kg lbs

591101 110TT1.5 12 1.5 2.0 Composite 110 28 62 10 22 200A- 589012

591482 140TT2.0 12 2.0 2.7 Composite 140 37 81 13 29 200A- 589012

Fig 6.2.1 Fig 6.2.2 Fig 6.2.3

GB

Loading...

Loading...