6

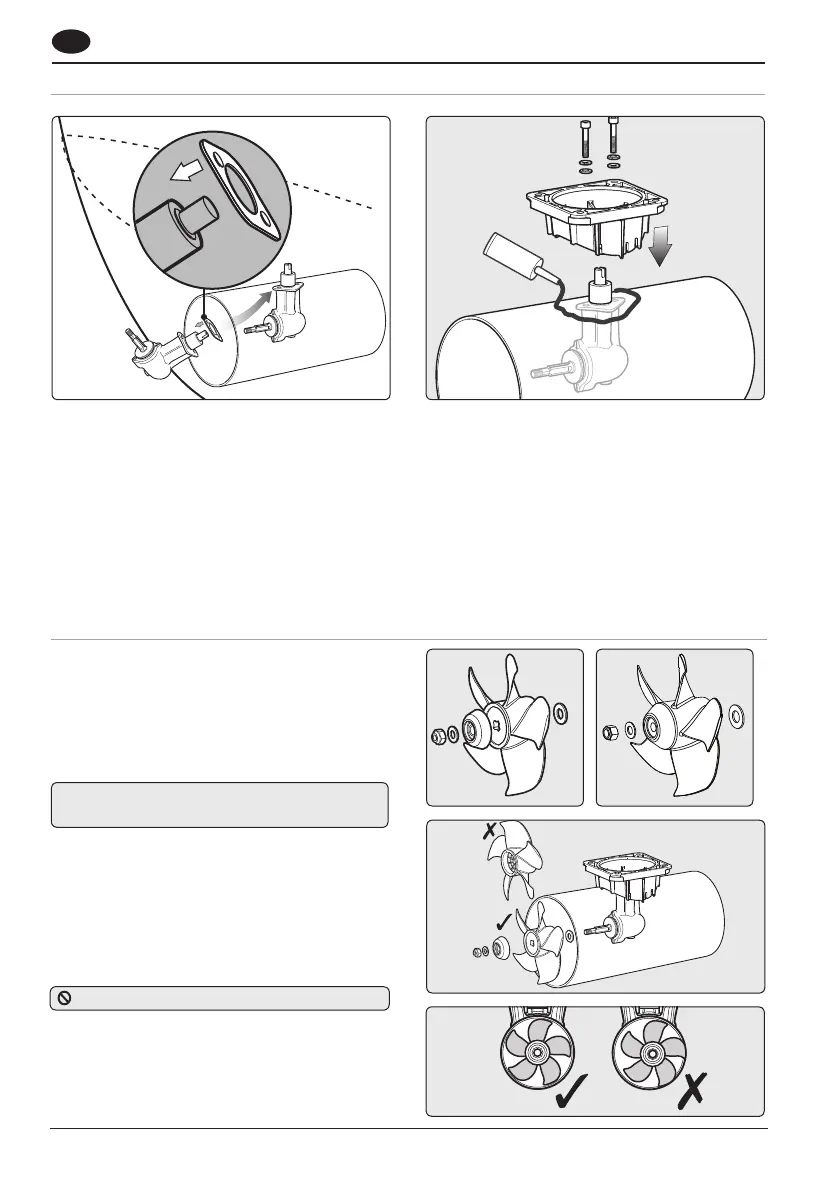

3.5 Propeller assembly

GB

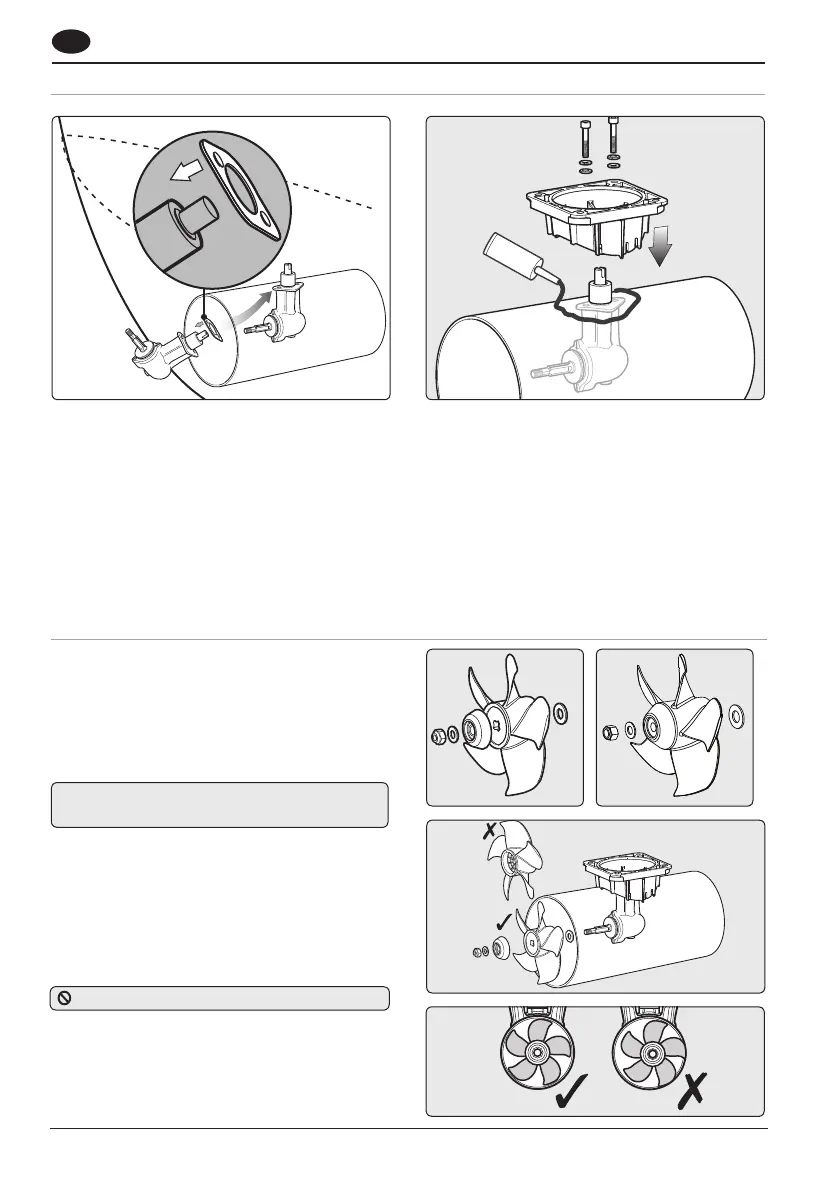

NOTE: Illustrations based on 140TT saddle.

To suit the wiring configuration supplied fit the

thruster propeller on the port side.

Place gasket on hub and locate through centre

hole. Sealant can be applied to gasket and flange

to aid sealing.

NOTE: To achieve the correct position of the propeller

in the tunnel the gasket must be inplace.

Check the hub gasket is in place.

Fig 3.5.1 - Assemble propeller as shown: nyloc nut

onto propeller shaft.

Note: Tighten each bolt alternately a number of

times to full torque.

NOTE: Poor exterior tunnel surface could cause

leakage and noise. Apply sealant to this area as

required (Fig. 3.4.2).

Apply zinc chromate paste or marine grease to

location bore and assemble saddle onto hub

(SikaFlex® or similar maybe used to seal saddle in

place). Apply Blue Loctite® 243 to bolts and hand

tighten along with supplied washers (Fig. 3.4.2).

NOTE: Tighten to full torque within 10 minutes.

3.4 Installing hub unit and saddle

Check the propeller has been assembled in the

correct order.

Fig 3.5.2 - Tighten hub/saddle bolts to

5 Nm (3.7 lbs.) for 110

9 Nm (6.6 lbs.ft) for 140

Check that propeller is centred and free turning

(within 10 minutes of applying Blue Loctite® 243).

Antifoul propeller if desired.

DO NOT allow propeller to touch tunnel.

110TT140TT

Fig 3.4.1 Fig 3.4.2

Fig 3.5.2

Fig 3.5.1

Fig 3.5.3

Loading...

Loading...