Maintenance

3.6.6 Cleaning the Parts and Checking for

Wear

Inspect all surfaces for scratches, marks, running-in

tracks or other damage. If possible, carefully smooth the

surfaces with emery paper.

If the parts are considerably damaged,

especially sealing surfaces or keyways,

replace them. In the case of seals and O-

rings always use new parts.

Using suitable wires, ensure that all oil channels are

clear of dirt. Blow compressed air through the channels

and clean all parts with a suitable solvent and then dry

them thoroughly with compressed air.

Check that all keys are clean and fit snug in their

keyways and that the cams and the ring gear can be pus-

hed without difficulty onto the shaft with its keys.If neces-

sary, rub the parts with emery paper and then clean

them again.

Unscrew and clean the gas ballast valve. All parts, inclu-

ding gaskets and O-rings needed for assembly, should

be moistened with pump oil.

3.6.7 Reassembling the Pump

Reassemble the pump in the reverse sequence.

Observe the following:

Inserting the intermediate plate

When pulling the intermediate plate (12/2) back in (spe-

cial tool 8), ensure that the O-ring (12/3) is not damaged.

Counterbalancing

When installing the ring gear and cams, make sure that

the cams and ring-gear counterbalance are fitted alter-

nately at the top and bottom so that the pump remains

counterbalanced (see Fig. 3).

Inserting the radial shaft seal

Using a suitable tool, force in the radial shaft seal from

the interior side of the front end plate (for position of radi-

al shaft seal, see Fig. 12).

Selecting the shims

One or more shims (9/23) have to be inserted between

the ball bearing (9/24) and the outer race (9/20). To

determine the correct thickness, proceed as follows:

As a trial, mount one or more 1 mm thick shims.

Attach the outer race, but tighten the screws only by

hand.

Using a thickness gauge, measure the gap between the

front end plate and outer race.

The correct thickness of the shims is obtained as follows:

1.00 mm minus gap measured plus 0.10 mm

Remove the 1 mm thick shims mounted for trial purposes

and insert shims of the thickness calculated.

Example: Gap measured is 0.70 mm

Thickness of shim(s) required:

1.00 mm - 0.70 mm + 0.10 mm = 0.40 mm

22

GA 02.200/8.02 - 10/02

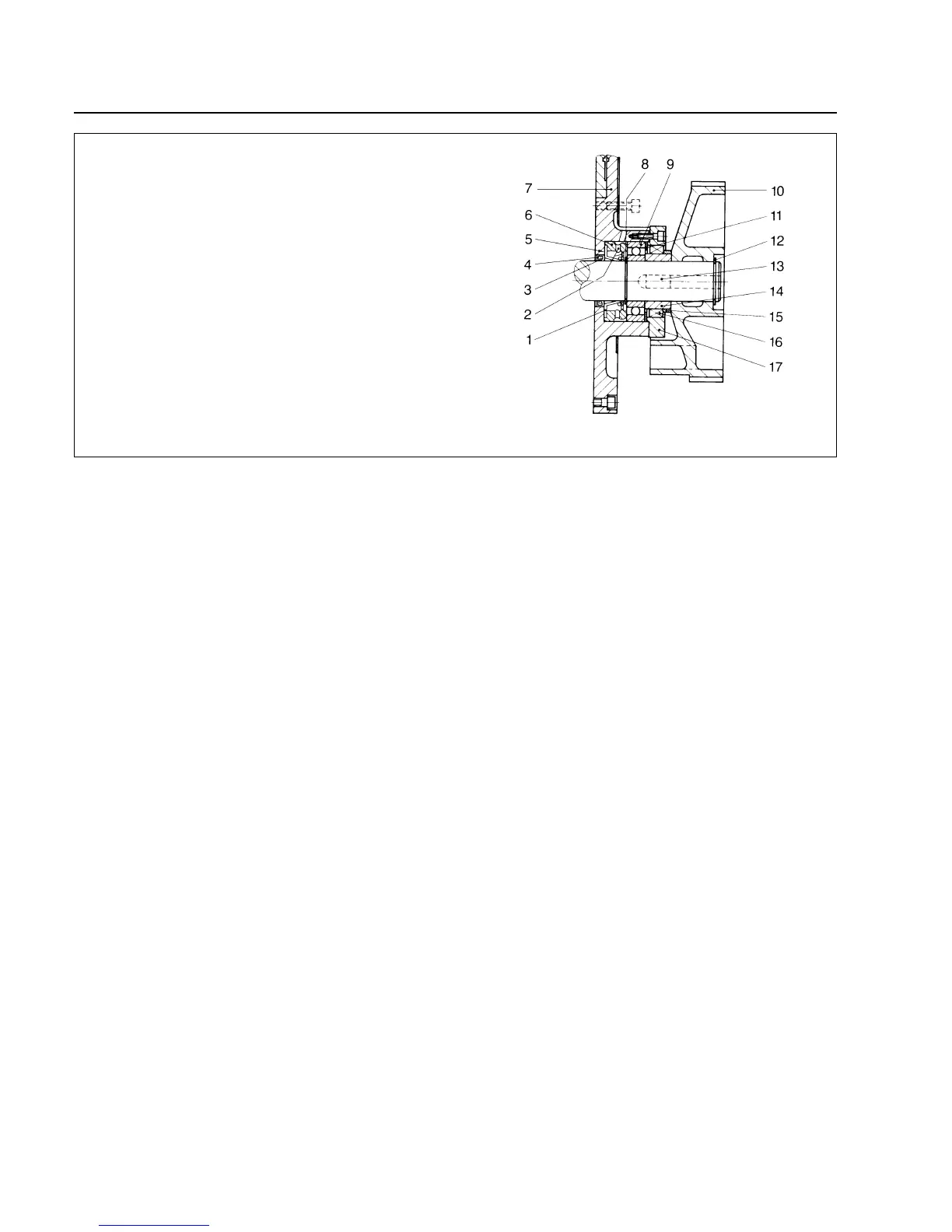

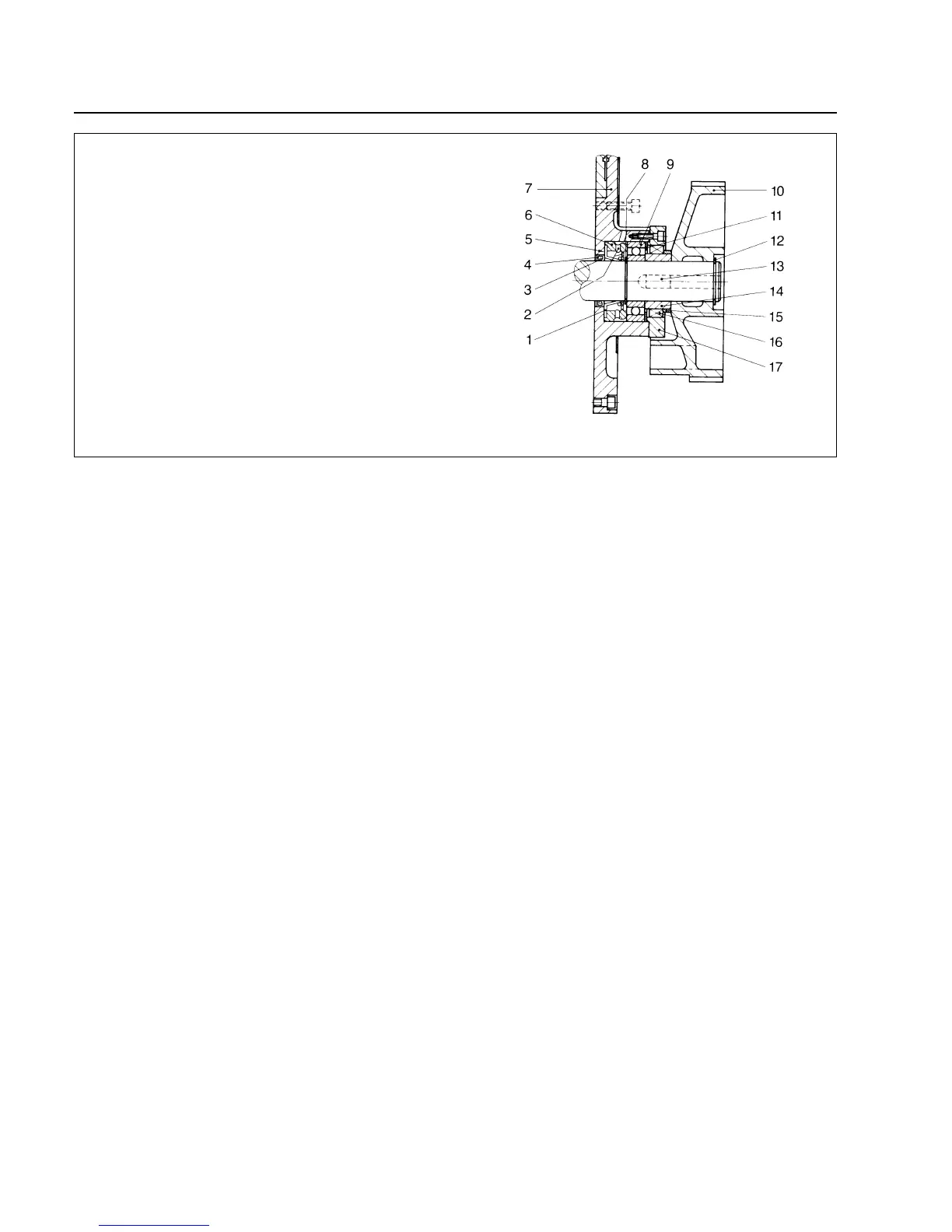

Key to Fig. 12

1 L-ring shaft seal (8/27)

2 Oil flow holes

3 Circular spring on ID of radial shaft seal

4 Radial shaft seal (8/7)

5 Bottom surface of bearing well

6 Spacer (8/26)

7 Front end plate (8/8)

8 Retainer ring (8/25)

9 Bearing (8/24)

10 Ring gear (8/18)

11 Shims (8/23)

12 Retainer ring (8/17)

13 Key

14 Inner race (8/22)

15 Spacer (8/19)

16 Reverse lock (8/21)

17 Outer race (8/20)

Fig. 12 Cross-section of the bearing in the motor lid (see also Fig. 9)

Caution

Loading...

Loading...