GA 02.200/8.02 - 10/02

25

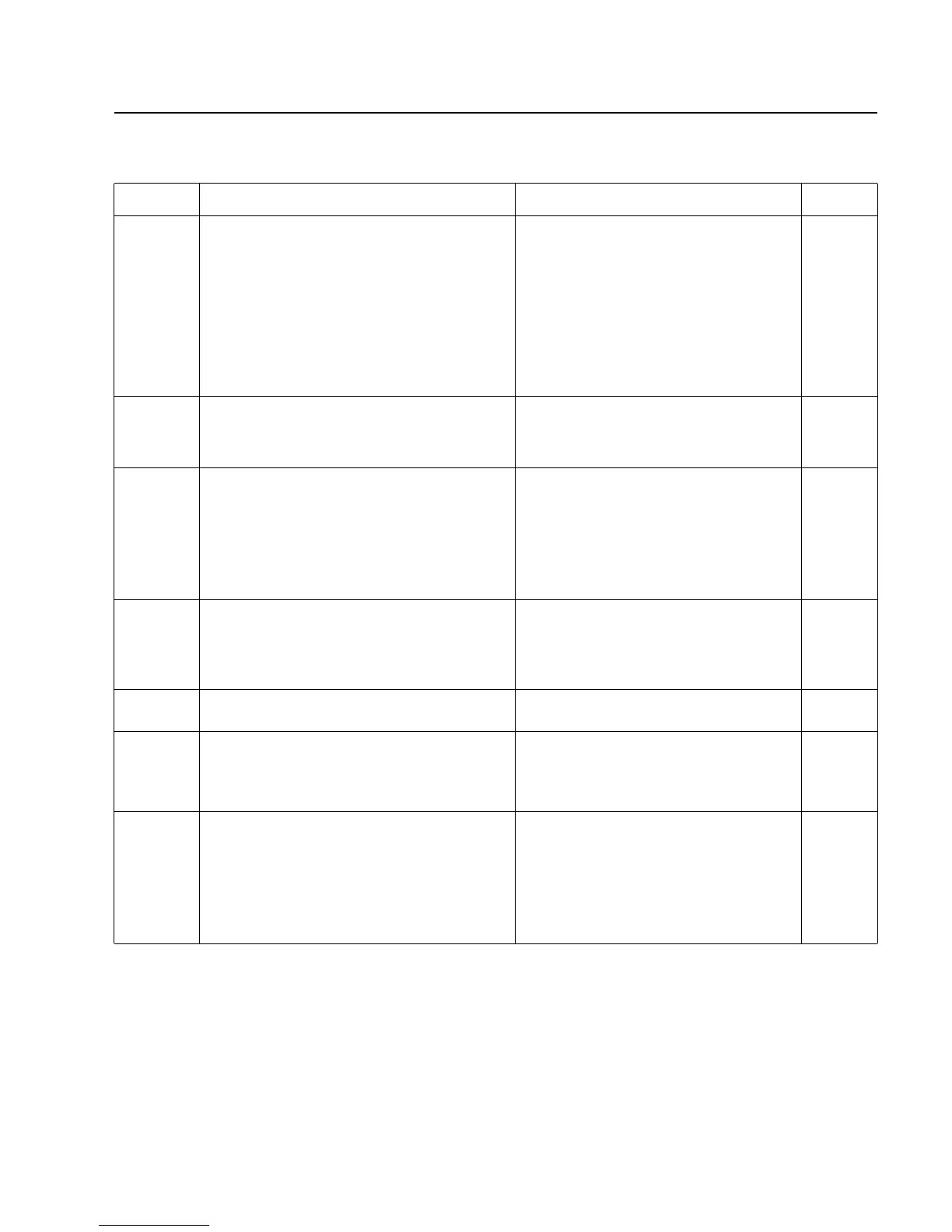

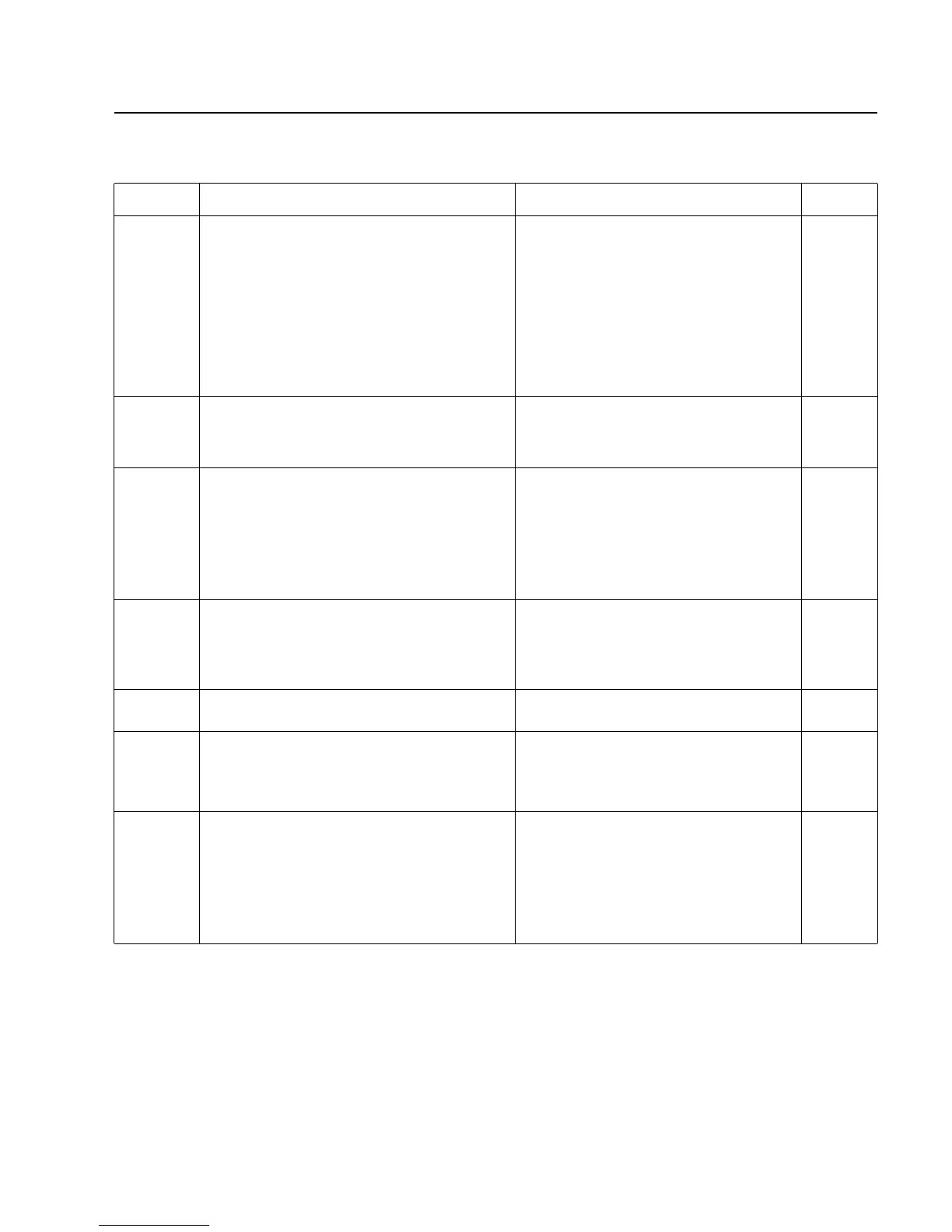

Troubleshooting

Pump gets hotter

than previously

observed.

Fault Possible cause Remedy

Pump is seized

up.

Oil has broken down due to oil not being changed often enough

or to pump overheating.

Corrosion of metal surfaces due to condensation

in pump.

Oil has become resinified.

Inadequate lubrication of pumping chamber due to clogged oil

channels.

Foreign particles in the pump.

Repair the pump; precaution: change the oil more often or

do not let the pump get so hot (see fault "Pump gets hotter

than previously observed.").

Repair the pump; precaution: run the pump with gas ballast

or install a condensate trap.

Repair the pump; precaution: install an oil filter or use diffe-

rent oil.

Repair the pump.

Use an intake filter.

Pump looses oil. Radial shaft seal is faulty.

Too much oil in gear housing.

Oil-drain plugs are not tight.

Gaskets are damaged.

Impact panel in the exhaust box is faulty

Repair the pump.

Drain the oil, fill in correct oil quantity.

Replace the gaskets of oil-drain plugs or

the oil-drain plugs.

Replace the gaskets.

Repair the impact panel.

*) This column refers to the section in the Operating Instructions that contains the applicable repair information.

1) Bubble test. Let the pump run at operating temperature with degassed oil, without gas ballast and with closed inlet port.

Immerse the exhaust line in a vessel with water. If a steady flow of bubbles appears, the pump has an external leak.

Repair-

note

Air intake or discharge surfaces of the cooler

are obstructed or dirty.

Ambient or intake temperatures are too high.

Oil cycle is not working.

Oil has broken down or is contaminated.

Incorrect oil level, not enough oil in the pump.

Installed exhaust filter or exhaust line is obstructed.

Exhaust valve is malfunctioning.

Continuous intake pressure > 200 mbar.

Gas ballast lines have a leak.

Excessive internal friction due to faulty parts.

Continuous intake pressure > 500 mbar (absolute).

- Insufficient lubrication.

Set up the pump correctly or clean the cooler.

40 °C max. are permissible.

Clean or repair the oil lines and channels.

Change the oil.

Top up oil, note correct oil level.

Replace the exhaust filter or clean the exhaust line.

Repair the valve.

Change the operating conditions, continuous intake

pressure < 200 mbar.

Repair the lines.

Repair the pump.

Change the operating conditions, continuous intake pressu-

re < 500 mbar.

Replace the exhaust filter.

Drain the excess oil.

Alter the operating conditions.

Find the leak and seal it.

Replace the valve.

Installed exhaust filter is clogged or damaged.

Too much oil.

Intake pressure is too high.

Vacuum system or lines have a leak.

Exhaust valve is faulty.

Oil consumption

is too high, oil

mist in the

exhaust.

Oil comes from vacuum system.

SECUVAC valve is not installed or is obstructed.

Sealing surfaces of SECUVAC valve are damaged or dirty.

Motor turns in the wrong direction.

Too much oil.

Vapour pressure of oil is too high.

Excessive pressure in exhaust line.

Oil-drain plug or its O-ring is faulty.

Oil in the intake

line or vacuum

vessel.

Check the system.

Install a SECUVAC valve or repair it.

Clean or repair the valve.

Interchange two of the input leads at motor junction box;

replace the reverse lock.

Drain the excess oil.

Change the oil.

Clear the exhaust line or clean the installed exhaust filter.

Replace the oil-drain plug or O-ring.

Degas the oil or change the oil and clean the pump;

precaution: open gas ballast valve or insert a separator.

Check the operating conditions ahead and after the pump

Install the exhaust line with a downward slope or install a

condensate trap. Check operating conditions (vapour

tolerance).

Condensation in the pump due to

- too much vapour

- pump too cold.

Exhaust line is not installed correctly.

Oil is turbid.

Change the oil.

Change the oil (see fault "Pump gets hotter than previously

observed."). Check operating conditions.

Oil has broken down.

Oil is too hot.

Oil is unusually

dark.

Loading...

Loading...