GA 02.200/8.02 - 10/02

24

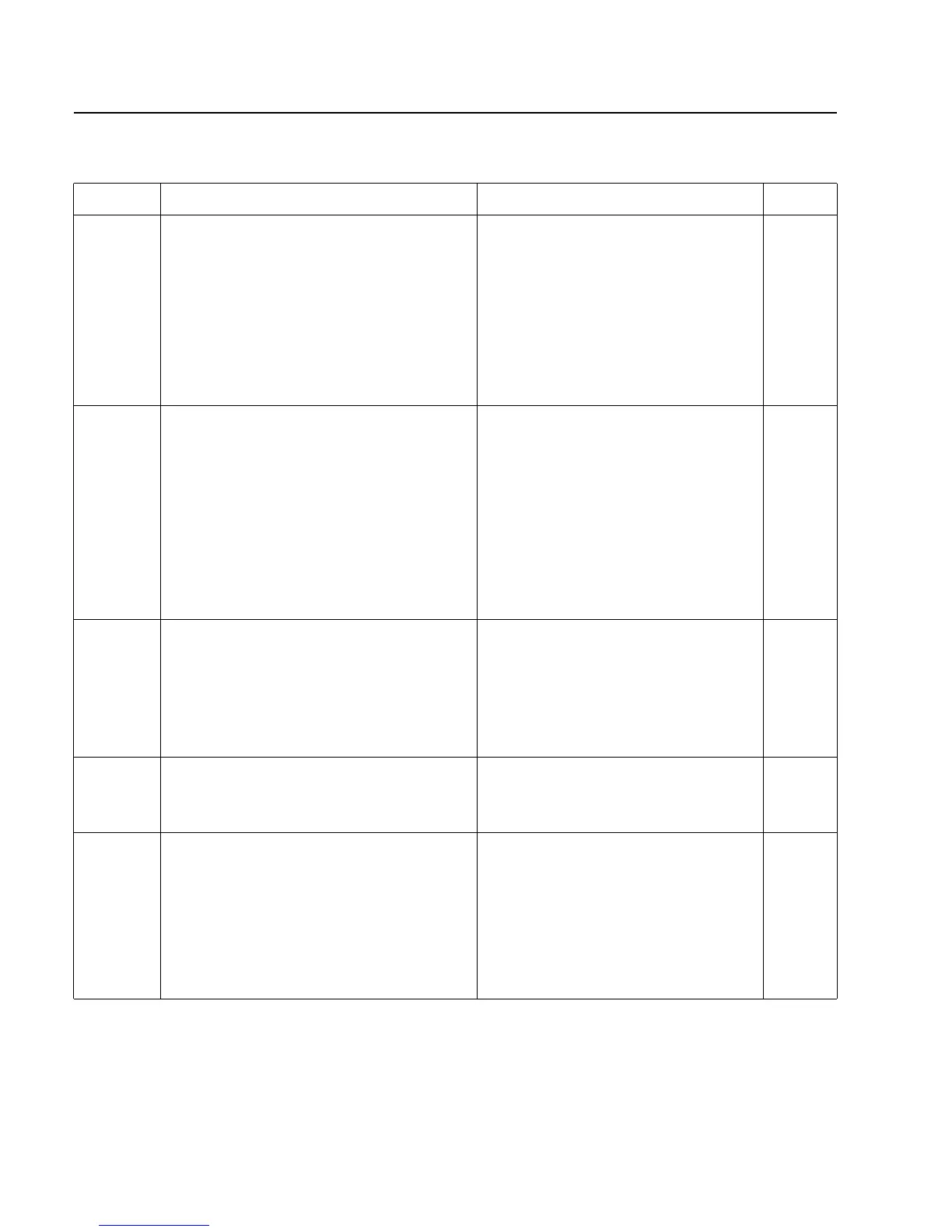

Troubleshooting

Fault Possible cause Remedy

Repair note

4 Troubleshooting

Pump does not

start.

Motor is connected incorrectly.

Reverse lock prevents start-up.

Blocked exhaust line.

Operating voltage does not match motor rating.

Motor protection switch is set incorrectly.

Motor is malfunctioning.

Oil temperature below 12 °C.

Oil is too thick.

Installed exhaust filter or exhaust line is clogged.

Too much oil has entered motor from gear housing.

Gear or bearings are obstructed or malfunctioning.

(See fault "Pump is seized up").

Connect the motor correctly (wiring diagram in junction box).

Interchange two of the input leads at motor junction box or

install the reverse lock correctly.

Remove the blockage.

Replace the motor.

Set the motor protection switch correctly.

Replace the motor.

Heat the pump and pump oil

or use different oil.

Change the oil.

Replace the filter, clean the exhaust line.

Repair the shaft seal on the motor, fill correct

oil quantity into gear housing.

Repair the pump.

Repair the pump.

Pump does not

reach ultimate

pressure.

Pumping speed

of the pump is

too low.

After switching

off the pump

under vacuum,

pressure in

system rises too

fast.

System has a leak.

SECUVAC valve is not installed or is obstructed.

Check the system.

Install a SECUVAC valve or repair it.

Silencer nozzle is clogged due to

- too much oil in the valve chamber

- contamination

Parts are worn:.

(shaft bushing, cam, ring gear, pinion lammellae and piston).

Cam or ring gear not properly mounted.

Motor bearing faulty.

Motor fan scrapes along the fan cowl.

Foot of the pump is loose.

Valve disc faulty.

Grooves in the shaft and the cam are worn out.

Connecting screw for the oil filter facility has a leak.

Wrong balancing (faulty ring gear).

Drain oil.

Clean nozzle.

Repair the pump.

Repair the pump.

Exchange the motor.

Exchange the fan cowl or repair.

Fix the foot of the pump.

Exchange the valve.

Exchange the faulty components.

Seal the connecting screw (O-ring).

Repair the pump.

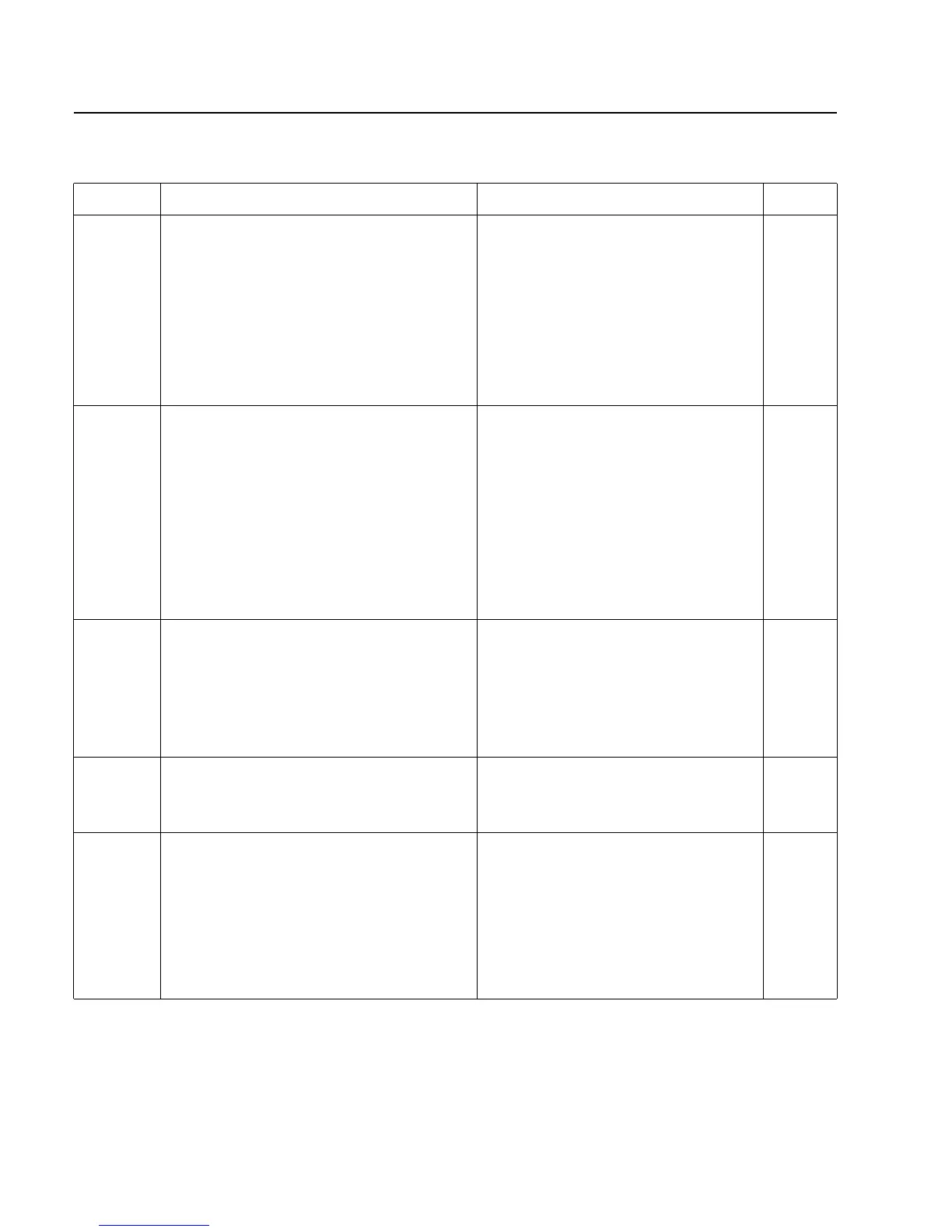

Pump is

unusually noisy.

Pump is to small.

Measuring technique or gauge is unsuitable.

External leak 1).

Installed SECUVAC valve closes.

Exhaust valve is malfunctioning.

Oil is unsuitable.

Gas ballast lines in valve chamber have a leak.

Gaskets at oil-drain plug (9/14) are faulty.

Inadequate lubrication of pumping chamber

due to clogged oil lines.

L-ring shaft seal and/or radial shaft seal is faulty.

Inadequate lubrication of pump due to

- insufficient oil

- clogged optional oil filter.

Internal pump parts are excessively worn.

Oil reservoir has not been mounted correctly.

Improperly fitted pistons and vanes after a repair.

Check process data, possibly change the pump.

Use correct method of measurement and instruments.

Repair pump.

Repair valve.

Repair valve.

Change the oil (possibly degas).

Repair gas ballast lines.

Replace gaskets.

Clean the pump.

Repair the pump.

Top up oil.

Clean the filter.

Repair the pump, replace worn parts.

Install the oil reservoir correctly.

Repair the pump.

Clean the dirt trap;

Precaution: install a dust filter in intake line.

Clean the filter.

Replace the filter elements.

Use adequately wide and short connecting lines. The diame-

ter of the connecting line should be the same as for the

connections at the pump.

Let the pump run warm with open gas ballast valve.

Repair the pump; replace the worn parts.

Leak detection and removal of the leak.

Dirt trap in the inlet port is clogged.

Installed dust filter is clogged.

Installed exhaust filter is clogged.

Connecting lines are too narrow or long (throttling).

Pump is too cold.

Internal pump parts are excessively worn.

Leak in the intake line.

Loading...

Loading...