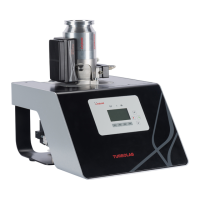

What to do if LEYBOLD TURBOVAC i(X) Water Pump is overloaded and cannot keep up its speed?

- MMichael YuAug 5, 2025

If your LEYBOLD Water Pump is overloaded and cannot maintain its speed, consider these potential causes and solutions: 1. High forevacuum pressure: Inspect the ultimate pressure of the backing pump. If needed, install a larger backing pump. 2. Excessive gas flow: Check for any leaks and inspect the process. 3. Defective fan: Replace the fan. 4. Water cooling is off: Turn on the water cooling system.