Maintenance

57300855170_002_C8 - 08/2021 - © Leybold

5.3 Bearing monitoring and conditioning

To ensure maximum reliability and bearing life the TURBOVAC have an inte-

grated system to manage the bearing condition. The status is indicated by a

blue LED on the pump.

The pumps have an integrated battery-backed real time clock that is con-

stantly monitoring pump storage time.

If the pump is stored without being run for more than 12 months, “Bearing

Run in Mode” (BRIM) is triggered the next time the pump is started to condi-

tion the bearing.

If the pump is stored without being run for more than 3 years, the pump will

indicate a bearing change is required before the pump is run.

Bearing on-site maintenance

The bearing of the TURBOVAC can be serviced on-site.

Instructions for bearing replacement can be found at https://manuals.leybold.

com/en/manual-frontend/products under the part no. of the bearing

exchange tool kit.

The following service tool kits and service parts are available.

TURBOVAC 850/950i 1350/1450i

Bearing kit part no. EK6529255 EK6529260

Bearing exchange tooling part no. EK850950 EK13501450

Bearing run in mode

Bearing run in mode (BRIM) is a start-up sequence for the pump designed to

precondition the bearing to optimise bearing life. The pump goes through a

number of speed steps before reaching full speed.

The BRIM process last around 4.3 hours and the LED indicates when this is

running.

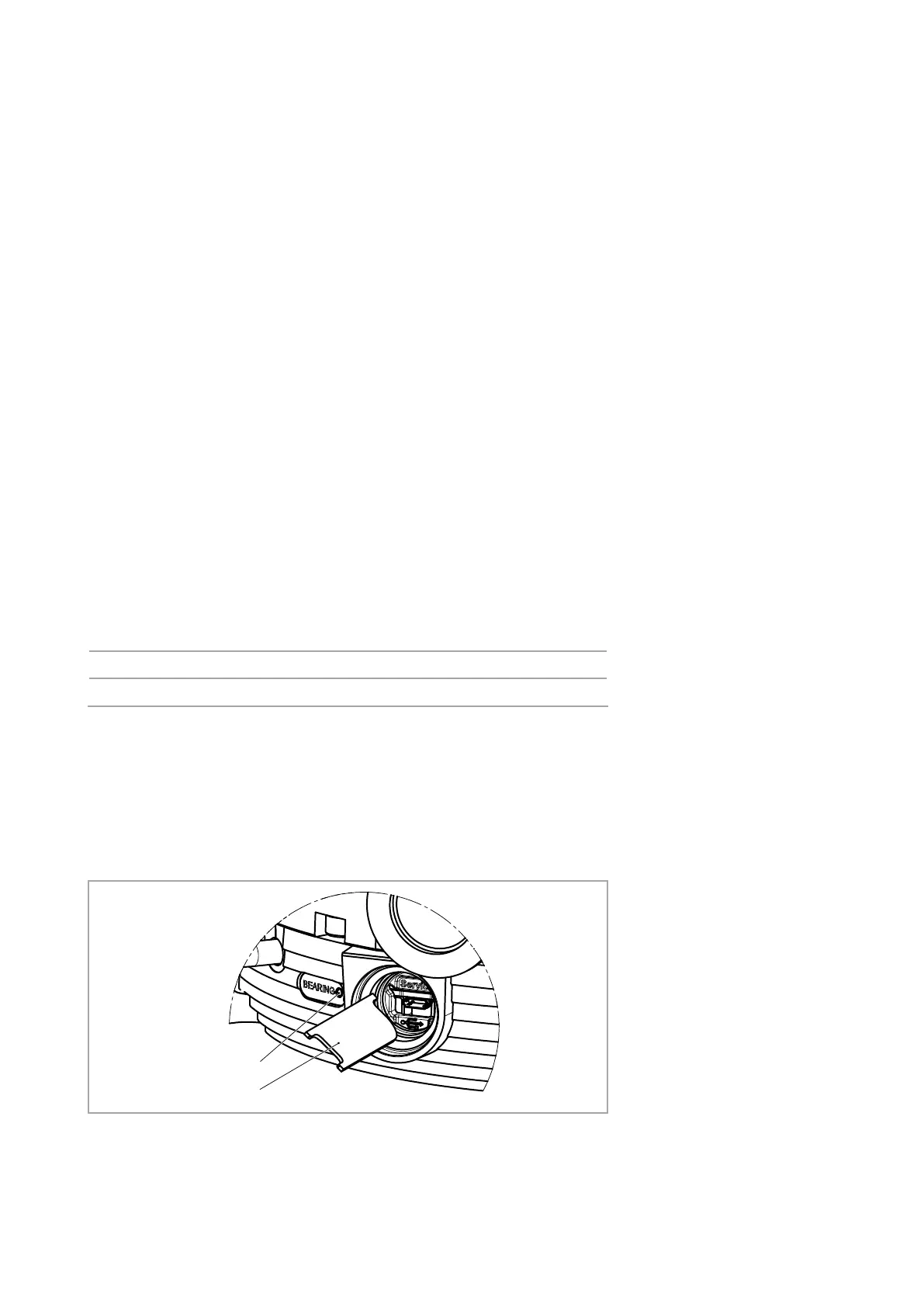

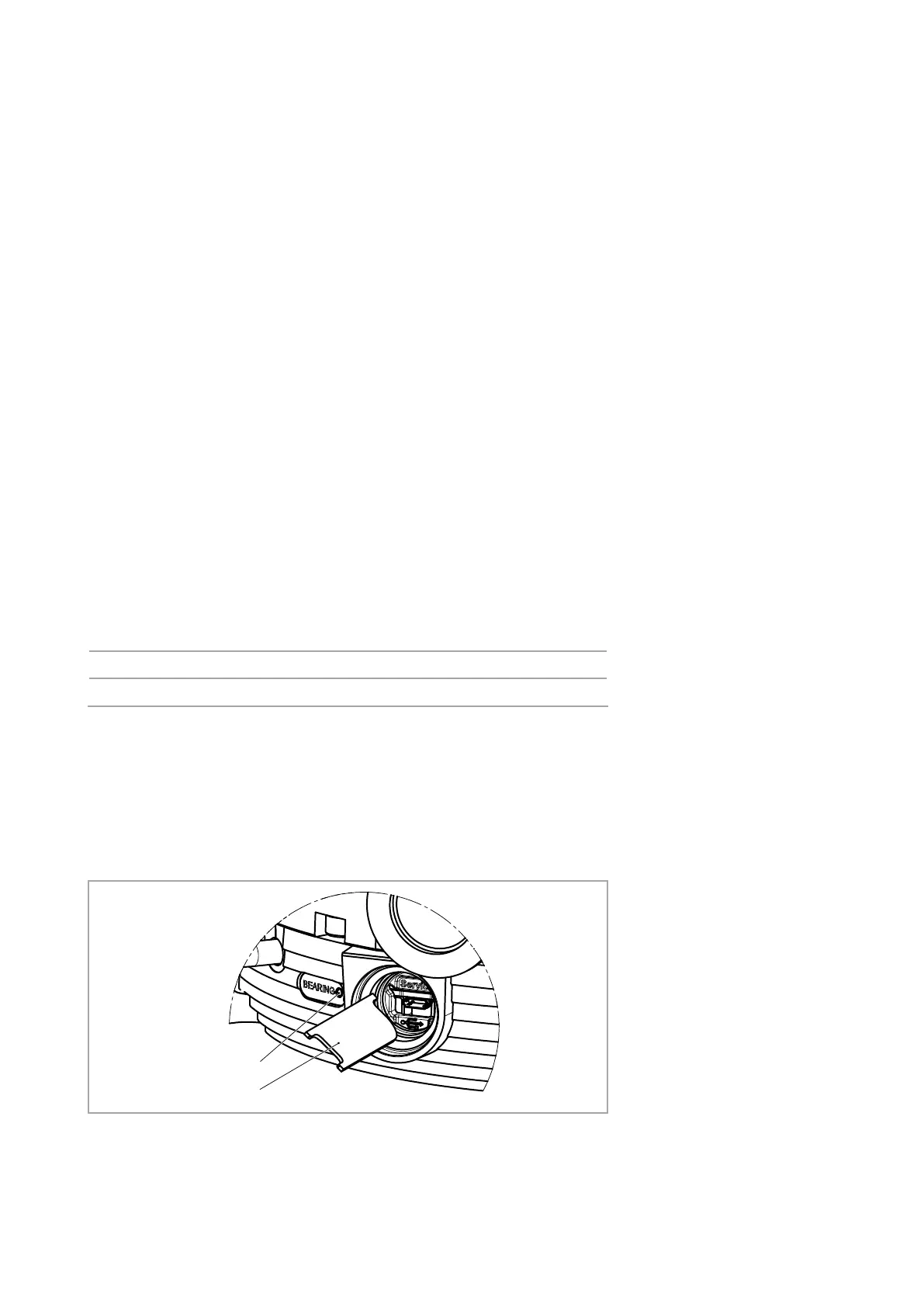

Bearing LED

Reset tool

Fig. 5.1 Use the reset tool

Loading...

Loading...