Operation

53300855170_002_C8 - 08/2021 - © Leybold

4.5 Venting

Refer to Section 4.1 for suited gases.

Venting Methods

There are three different methods of venting the turbomolecular pump.

The pump can be vented via the venting connection (VENT), by means of a

venting valve, a power failure venting valve, or a venting screw.

Cautious venting of the pump is possible from the high vacuum side, since

here the bearing forces will be lowest. When doing so, no free jet of gas must

be allowed to form on the rotor so as to avoid exposing the rotor to addition-

al forces.

When venting the pump through its foreline connection, neither oil nor par-

ticles may be entrained in the gas flow from the forevacuum side into the

pump.

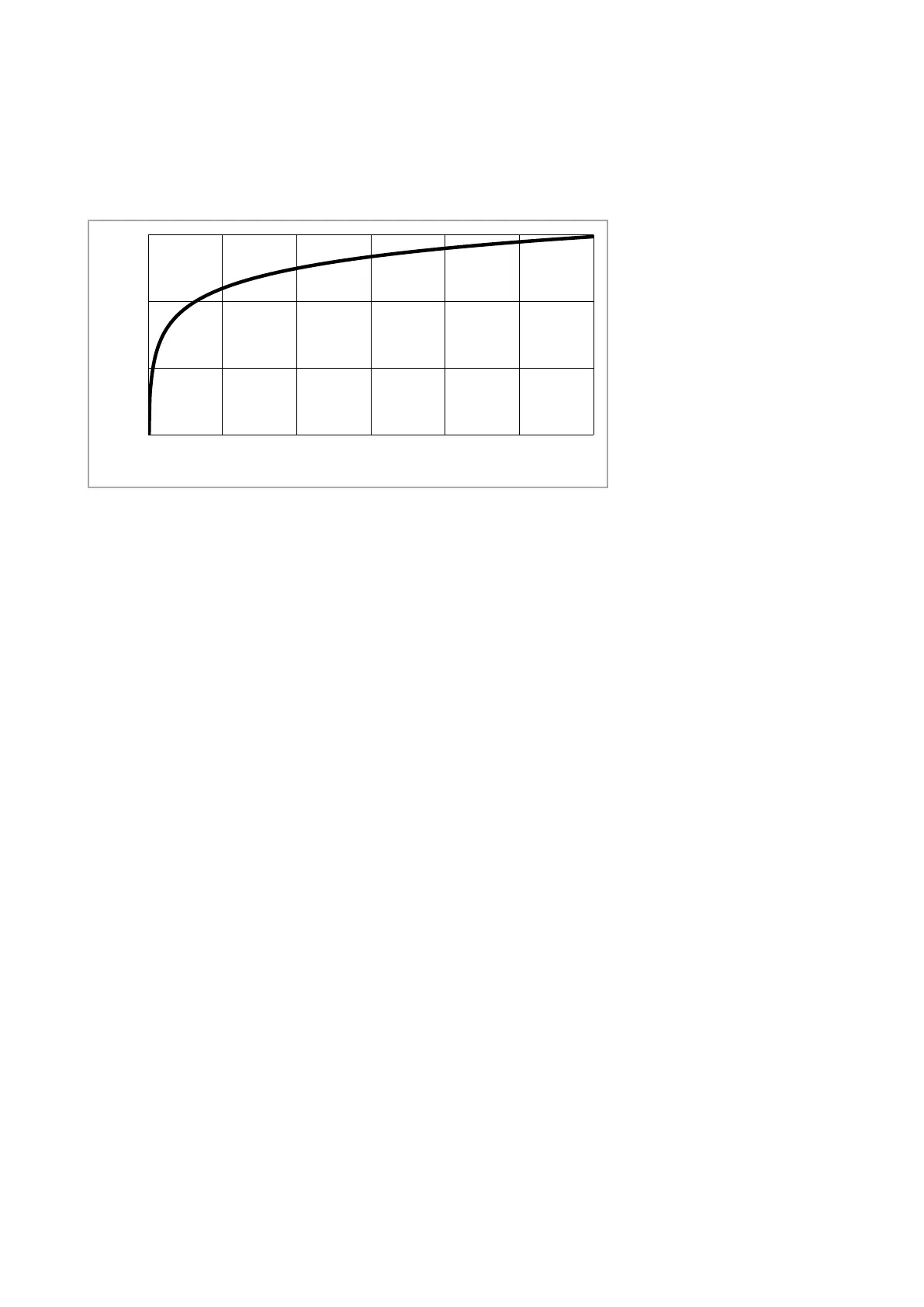

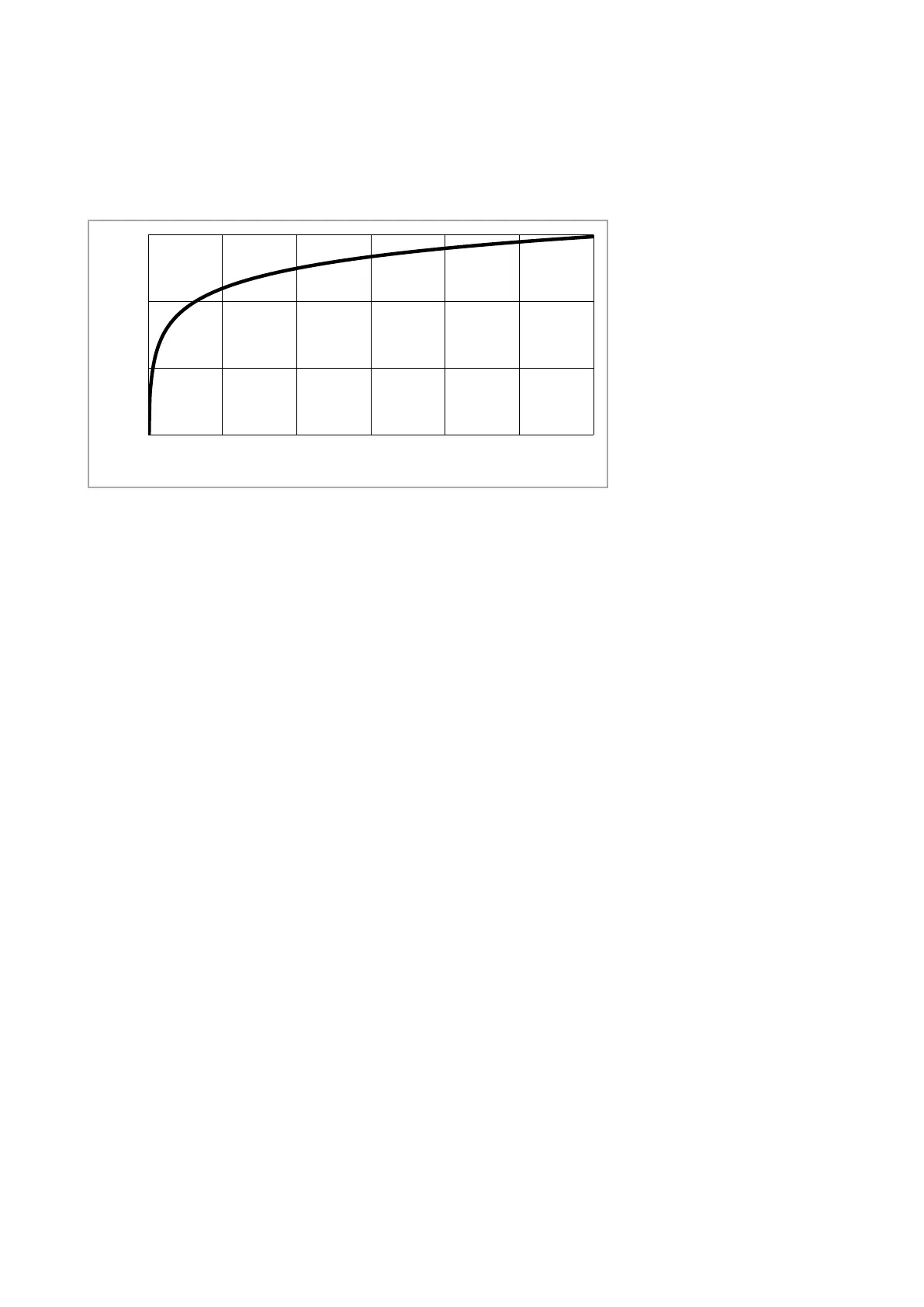

Speed of the Pressure Rise

All turbomolecular pumps may be vented at full speed

. However, the pres-

sure must not increase faster than specified through the pressure rise curve ,

see Fig. 4.2..

The pump must be vented significantly slower when there is the risk of

particles entering into the pump from the process. During venting, the flow

must be of the laminar type in both the vacuum chamber and the turbomo-

lecular pump.

The pump must not be vented to pressures above atmospheric pressure.

Speed

Pressure rise curve

Particles

1

10

100

0 50 100 150 200 250 300

Zeit [s]

Fig. 4.2 Maximum rise in pressure

Forevacuum pressure [mbar]

Time [s]

Loading...

Loading...