Installation

28 300855170_002_C8 - 08/2021 - © Leybold

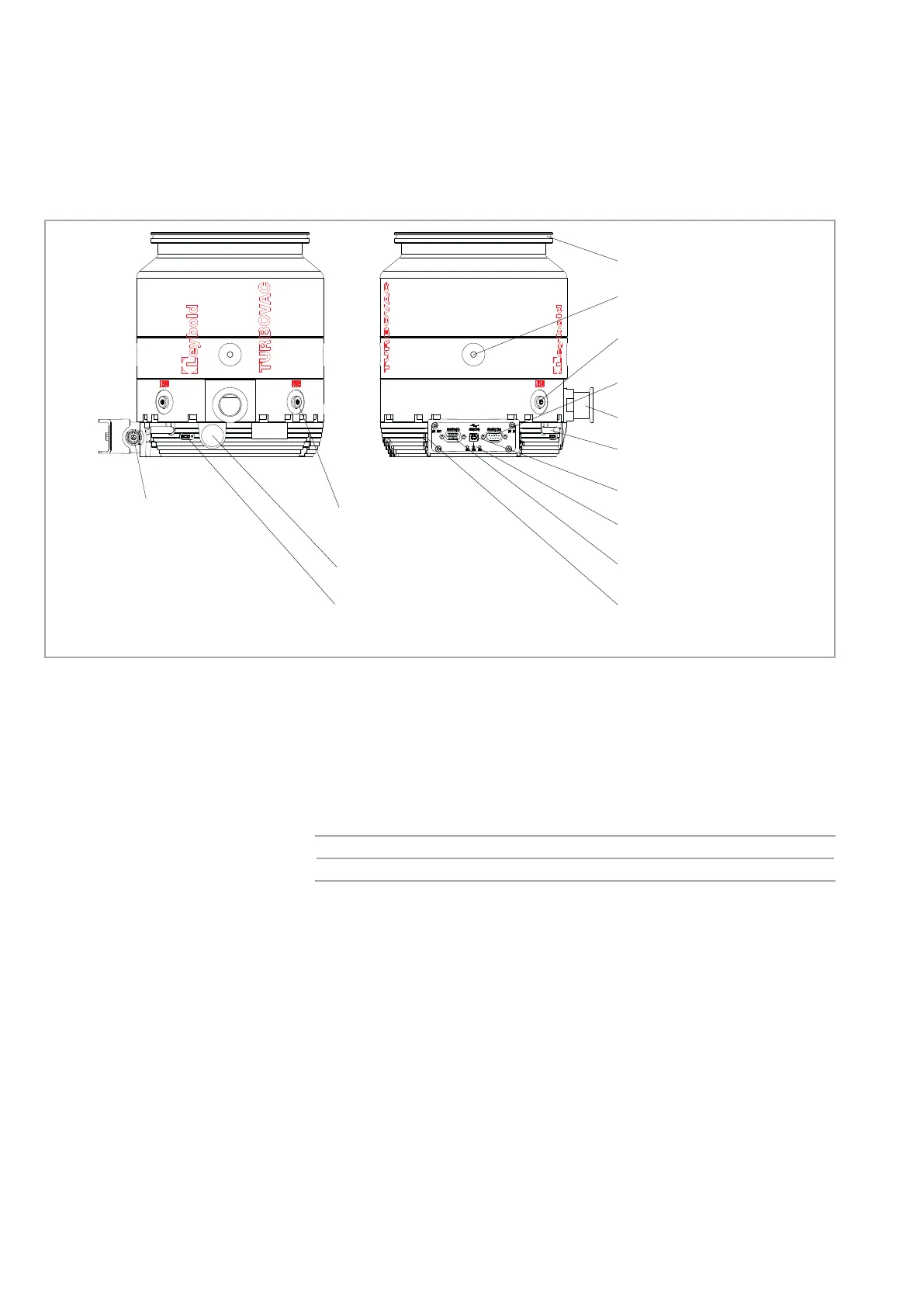

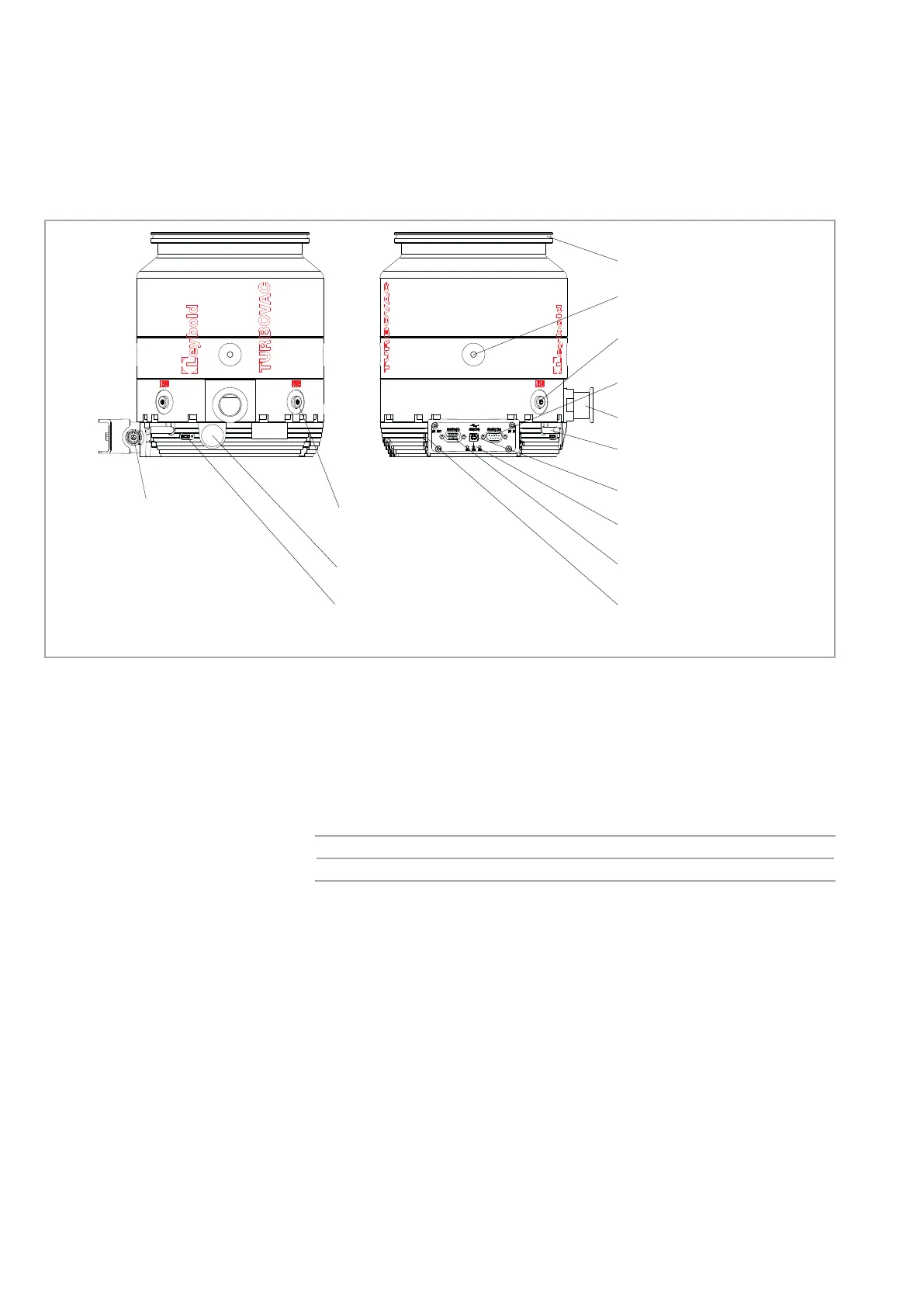

Hochvakuumflansch

4x Bohrung für Kranöse

Belüftungs-Anschluss

G1/8"

RS-485-Schnittstelle X104

Vorvakuum-Anschluss

48 V DC Stromanschluss

USB-Schnittstelle X106

LEDs

REMOTE-Schnittstelle X1

Zubehöranschluss DC OUT

(M8) X201

Sperrgas-Anschluss

G1/8"

USB-Schnittstelle Service

Lageranzeige (zeigt an, wenn

Lagerwechsel empfohlen wird)

Fig. 3.2 Connections

High-vacuum flange

4x Boreholes for eye-bolts

Venting connection

G1/8“

RS 485 interface X104

Forevacuum connection

48 V DC Power supply cable

USB interface X106

LEDs

REMOTE interface X1

Accessory connection

DC OUT (M8) X201

Purge gas connection

G1/8“

USB interface Service

Bearing status indication (indi-

cates when bearing service is

recommended)

Remove the transport seal from the intake flange and remove the desiccant.

Pay attention to maximum cleanliness when connecting.

In the case of a sudden rotor vane rupture or rotor-stator contact which may

occur in practice (caused, for example, by solid objects from the process

chamber entering the pump through the high vacuum flange), the following

torques need to be absorbed by the system:

TURBOVAC 850/950 i(X) max. 5 kNm

TURBOVAC 1350/1450 i max. 9 kNm

In most applications the pump is flanged to the high vacuum flange at the

apparatus. The pump can be mounted and operated in any desired attitude.

When using flange connecting elements in accordance with DIN 28404 (ISO-

F flange connection), ISO 1609 (ISO-K flange connection) or ISO 3669 (CF

flange connection), which fit positively to the pump flange, check the maxi-

mum load capacity of the connecting element. Not all flange components

can withstand the forces that occur in a crash.

If the strength of the component is not sufficient, there is the possibility of

providing an additional safeguard via the four threaded holes for the eye-bolts

for transport. Ensure that the mountings can withstand the braking torque.

Torque when the

rotor seizes

Do not connect a

power supply to this

connection!

Loading...

Loading...