1 Description

1.1 Design

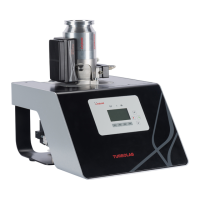

The TURBOVAC models 151 to 1100 are turbomolecular pumps featuring

lifetime lubricated bearings. These units are engineered to pump vacuum

chambers down to pressures in the high-vacuum range. A TURBOTRONIK

or Turbo.Drive TD20

classic

frequency converter and a forevacuum pump are

re quired for the operation of the TURBOVAC.

1.2 Standard equipment

The TURBOVAC is shipped in a sealed PE bag which also contains a desic-

cant. The maximum effective life of the desiccant is one year.

■

For high-vacuum port with ISO-K flange:

Inlet screen, centering ring with FPM sealing ring; outer ring.

■

For high-vacuum port with CF flange: Inlet screen.

■

For high-vacuum port with ANSI flange: Inlet screen.

Forevacuum port: Centering ring with O-ring and clamping ring.

Both the purge gas port and the venting port are blank ed off for shipping.

In addition the pivoted threaded fittings used to make the coolant connection

are included as standard equipment for the TURBOVAC 151, 361 and 600; if

needed, they can be used to replace the hose nipples installed at the factory.

The electronic frequency converter and the connector cables required for

operation are not included as standard equipment with the pump.

——————————

PE = Polyethylene

FPM = Fluoroelastomer, resistant to temperatures of up to 150°C (300 °F)

Loading...

Loading...