3.5 Forevacuum connection

The high vacuum pressure level which can be achieved is a function of the

volume of gas flow Q to be pumped and the forevacuum pressure.

We recommend using TRIVAC rotary vane pumps for this purpose.

Connect the clean forevacuum line. The connecting flanges must be clean

and undamaged. The cross section of this line must be so wide that safe

opera tion of the pump can be ensured.

The forevacuum line must be tight. Hazardous gases can escape at leaks

or the gases being pumped can react with air or humidity.

Observe Safety Information 0.4.5.

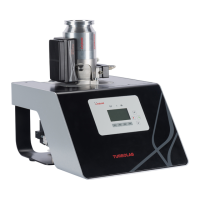

Fig. 3.7 is a schematic diagram of a pump system incorporating a turbomo-

lecular pump and a TRIVAC forevacuum pump with an anti-suckback valve.

A separate safety valve must be provided for oil-sealed forevacuum pumps

without an anti-suckback valve. The safety valve prevents oil flowing back

from the forevacuum pump into the turbomolecular pump when the system is

not running.

To ensure that the forevacuum space at the turbomolecular pump is kept

largely free of oil vapors during operation, as well, we recommend installing

an adsorption trap in the forevacuum line. Alternatively purge the forevacuum

line with inert gas. In this case the pressure in the forevacuum line must be

over 10

-2

mbar.

Provide a roughing line to achieve the shortest cycle times.

Ensure that the pump is sufficiently isolated against vibrations generated by

the forevacuum pump.

No forces from the piping system may be allowed to affect the turbomolecu-

lar pump. Support the piping correspondingly or decouple through flexible

joints.

Forevacuum pump

DANGER

Safety valve

Adsorption trap

Loading...

Loading...