3 Maintenance

3.1 LEYBOLD Service

If equipment is returned to LEYBOLD, indicate whether

the equipment free of substances damaging to health or

whether it is contaminated. If it is contaminated also indi-

cate the nature of the hazard. For this you must use a

form which has been prepared by us which we will pro-

vide upon request or you may copy the from which has

been reproduced on the next to the last page of this

handbook.

Please attach this form to the equipment or enclose it

with the equipment.

This „Declaration of Contamination“ is required to meet

German Law and to protect our personnel. Leybold must

return any equipment without a „Declaration of Contami-

nation“ to the sender’s address.

Before shipping, fit the yellow screw-on seals on to the

connections EXHAUST (3/5) and GAS BALLAST (3/6)

(see Chapter 2.1.2).

3.2 Maintenance Plan

Maintenance work should be done on the UL 200 as

required.This work will normally be limited to exchanging

the oil in the D 2,5 E rotary vane pump and the built-in

air filters.

As a preventive measure it is recommended that you

check the rotary vane pump once a month. Here note

should be taken of the oil level and the colour of the oil.

For details on this please refer to the Operating Instruc-

tions GA 01.600 for the TRIVAC D 2,5 E which have

been enclosed.

Caution Only Arctic oil (Cat. No. 200 28 191)

must be used in the TRIVAC D 2,5 E in

the UL 200.

The monthly interval for the check is just a nominal peri-

od. If the leak detector is used heavily, in particular in the

sniffer mode, then this check should be performed more

frequently. The rotary vane pump is located on the side

of the mechanical section at the bottom of the leak

detector.

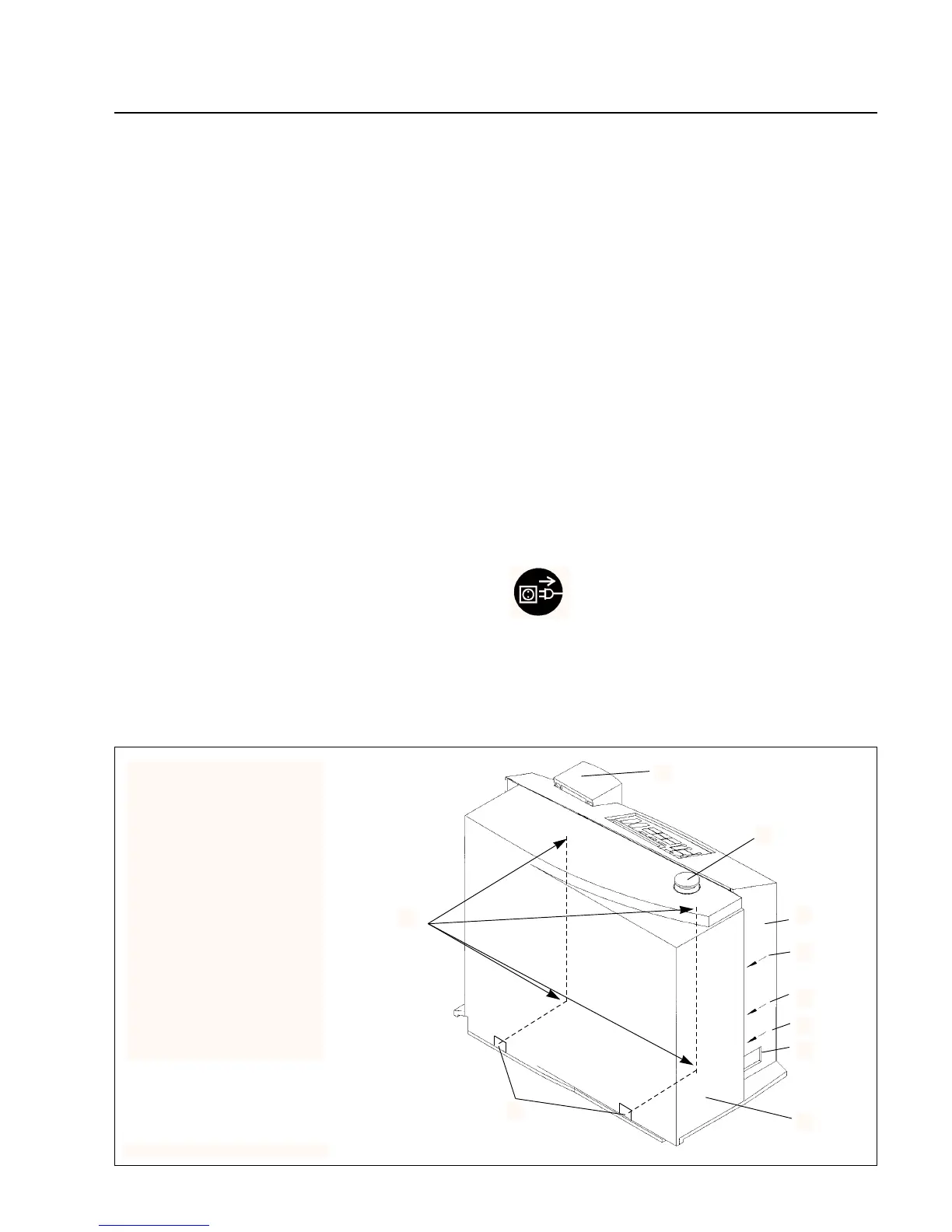

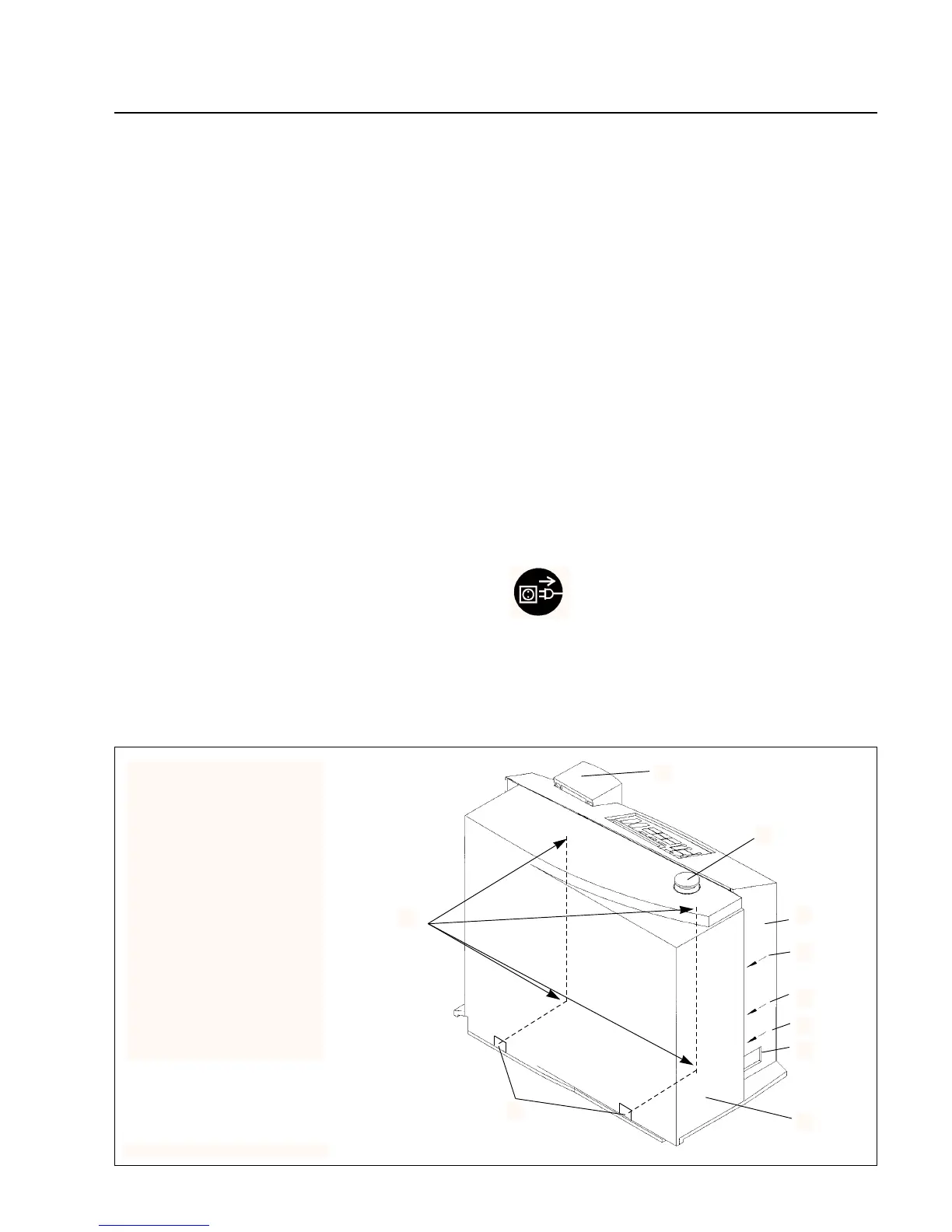

3.2.1 Opening the UL 200

Switch the UL 200 off.

Pull the mains cord on the UL 200.

Remove the cover (6/8) for the mechanical section.

Separate the UL 200 from other vacuum components at

the test port (6/2).

Turn the UL 200 so that it is orientated in the same way

as shown in Fig. 6.

31

TH 10.211/8.02 - 12/97

4

5

6

7

8

9

1

10

2

3

Key to Fig. 6

1 Hand unit

2 Test port

3 Cover for the electronics section

4 VENT input

5 Connection for the exhaust line

6 Gas ballast connection

7 Mains switch with mains fuses

8 Cover for the mechanical section

9 Openings for removal of the

cover for the mechanical section

10 Four screws for loosening the

cover for the electronics section

Fig. 6 View of the mechanical side

Loading...

Loading...