4-1

Copyright © LG Electronics Inc. All rights reserved.

Only training and service purposes

COMPONENT TEST

NOTE:

1. The most common cause for control failure is corrosion on connectors.

Therefore, disconnecting and reconnecting wires will be necessary throughout test procedures

2. ALL units in the rst few days of use should be checked for mis-wiring or loose connections

1. All/tests/checks should be made with a VOM or DVM having a sensitivity of 20,000 ohms per-volt DC, or

greater.

2. Check all connections before replacing components, looking for broken or loose wires, Failed terminals, or

wires not pressed into connectors far enough.

3. Resistance checks must be made with power cord unplugged from outlet, and with wiring harness or

connectors disconnected.

Before testing any of components, perform the following checks:

WARNING

t%JTDPOOFDUQPXFSTVQQMZDPSEGSPNUIFPVUMFUCFGPSFTFSWJDJOH

t3FQMBDFBMMQBOFMTBOEQBSUTCFGPSFPQFSBUJOH

t3FDPOOFDUBMMHSPVOEJOHEFWJDFTBGUFSTFSWJDJOH

- Failure to do so can result in death or electrical shock

!

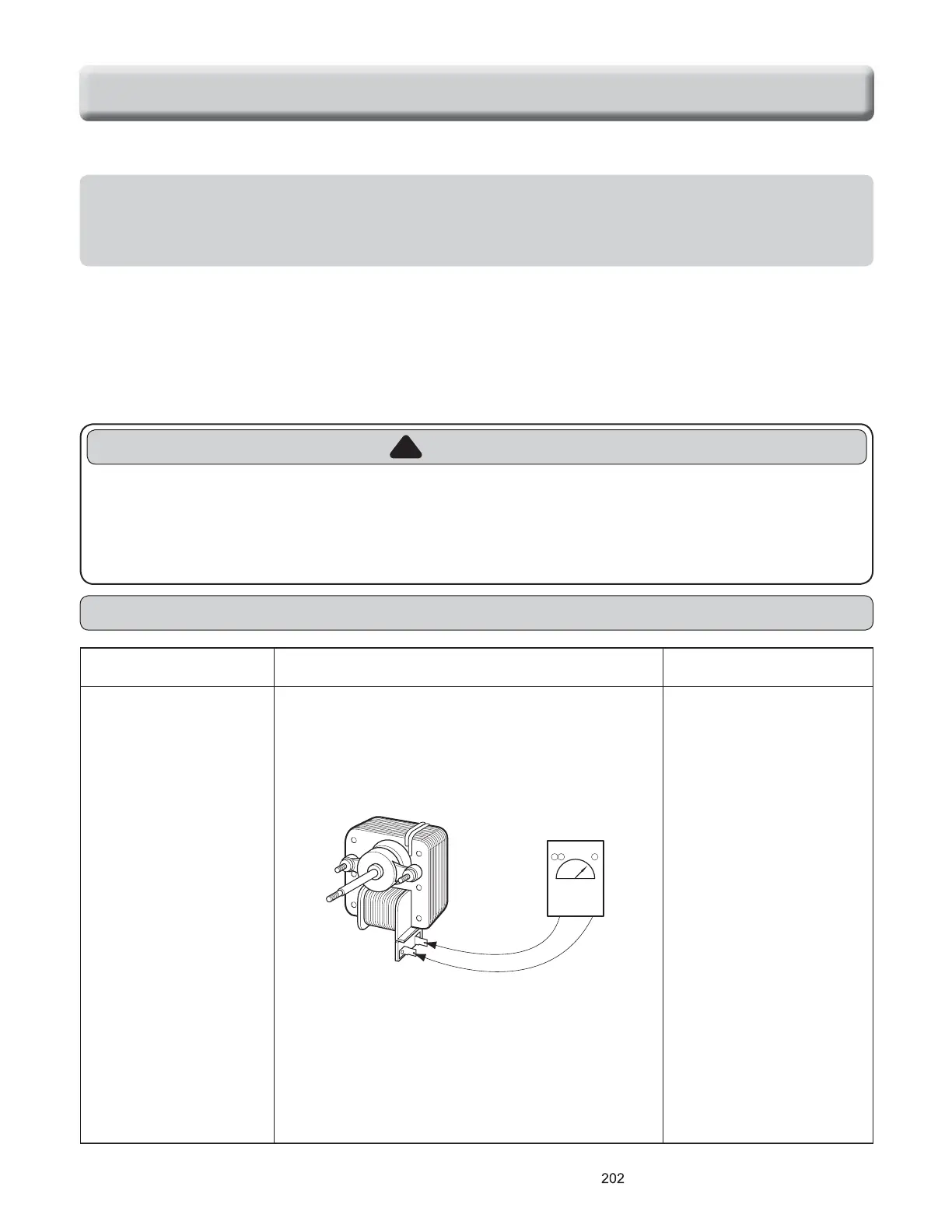

Convection Motor 1. Refer to page 3-10 for the servicing procedure

2. Measure the resistance

(Multiple meter scale: R x 1)

Components Test procedures 3FTVMUT

Normal: Approximately

103Ω

If not replace

Abnormal: Innite (open)

below 5Ω (shorted)

/05&#FMPXƆWBMVFXFSFUFTUFEBUSPPNUFNQFSBUVSF'¡$

1

Loading...

Loading...