Compressor

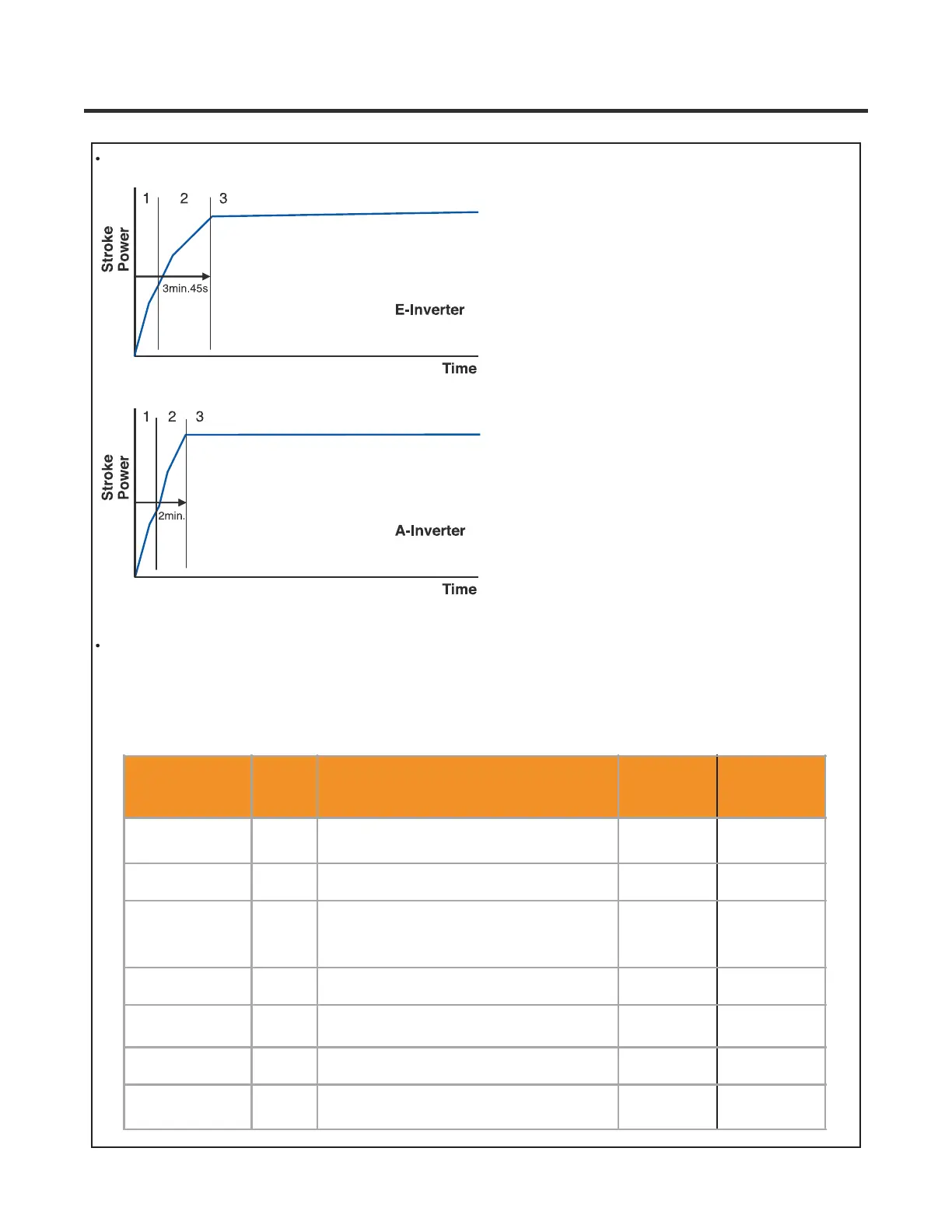

To reduce noise level, the piston stroke is slowly increased to full power during start up.

There are 6 protection logics designed to protect the linear compressor system. When a failure is detected,

the compressor will shut and will try to restart after a set period of time for each type of failure. The LED

located on the inverter drive PCB will flash the appropriate code to indicate the detected failure. This code will

continue to flash until the unit is disconnected from the power source.

Inverter Error Codes

Step 1) Start up - Half stroke interval for first 30

seconds.

Step 2) Ramp up - Stroke increases every 0.8sec until

maximum stroke length is reached (about 3

min, 15 sec)

Step 3) CVCF interval - 180V / 60Hz

Step 1) Start up - Half stroke interval for first 20

seconds.

Step 2) Ramp up - Stroke increases until maximum

stroke length is reached (about 1 min, 40 sec)

Step 3) VVCF interval - target voltage and frequency

controlled by Control Board signals

Inverter Error

Codes

code Requirement O Time The number

of LED

ashes

FCT0 5 |Vm, Im|> 2.5V+20% @ COMP o 30s 1

Stroke 10 |Stroke|>17.5mm 60s 2

No Connect 15 |Stroke|<=9.4mm &

While 4 seconds |AC Current|<0.05A

40s 3

Lock 25 |AC Current|>1.0A & |Stroke|<3.0mm 150s 5

Current 30 |Current|>3Ap 360s 6

7S020 =!pirT_oF_cu53MPI

Communication

Error

80rorre muskcehC-

27

Copyright © 2017 LG Electronics Inc. All rights

reserved. Only training and service purposes.

Loading...

Loading...