21

ENGLISH

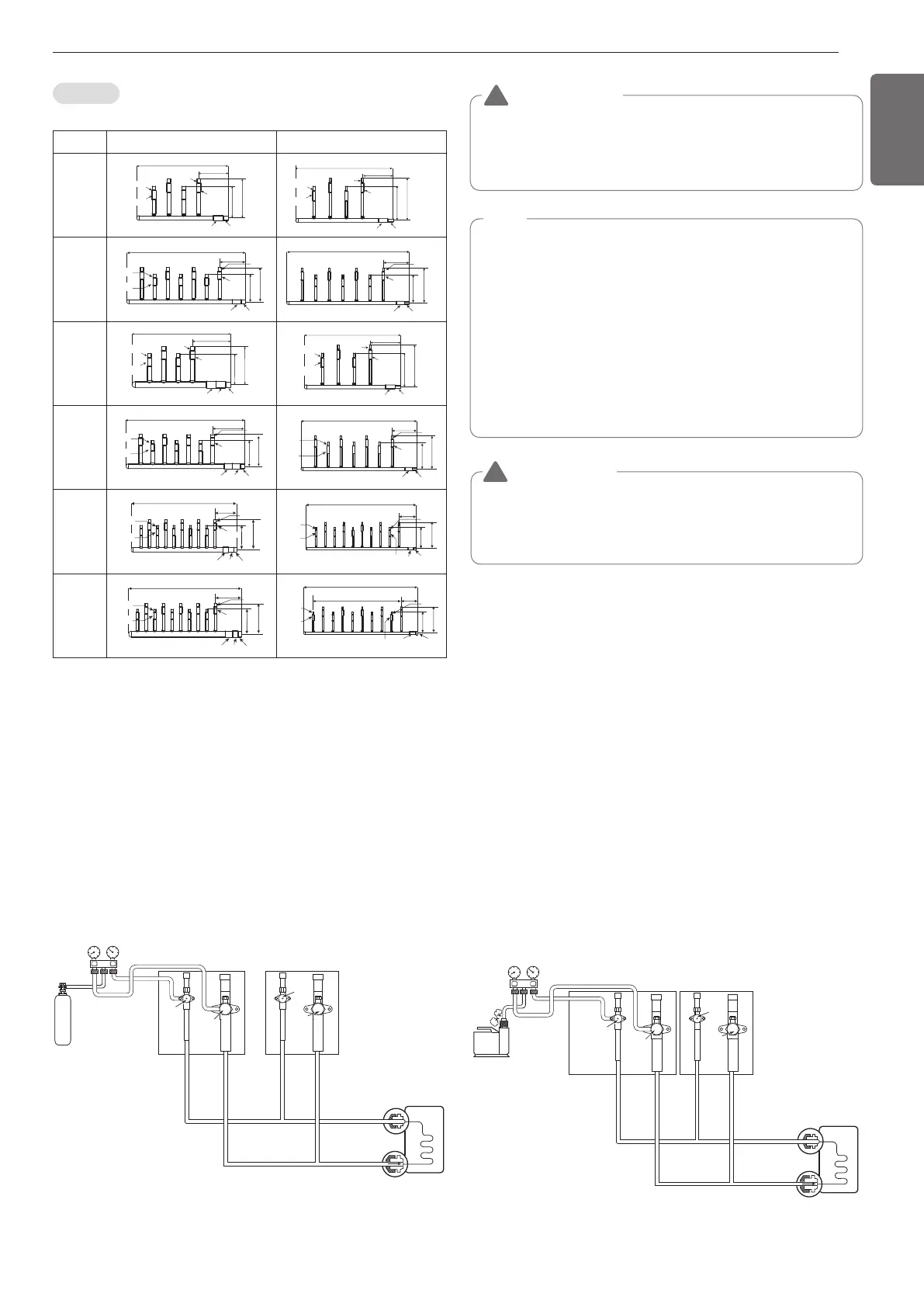

[unit:mm]

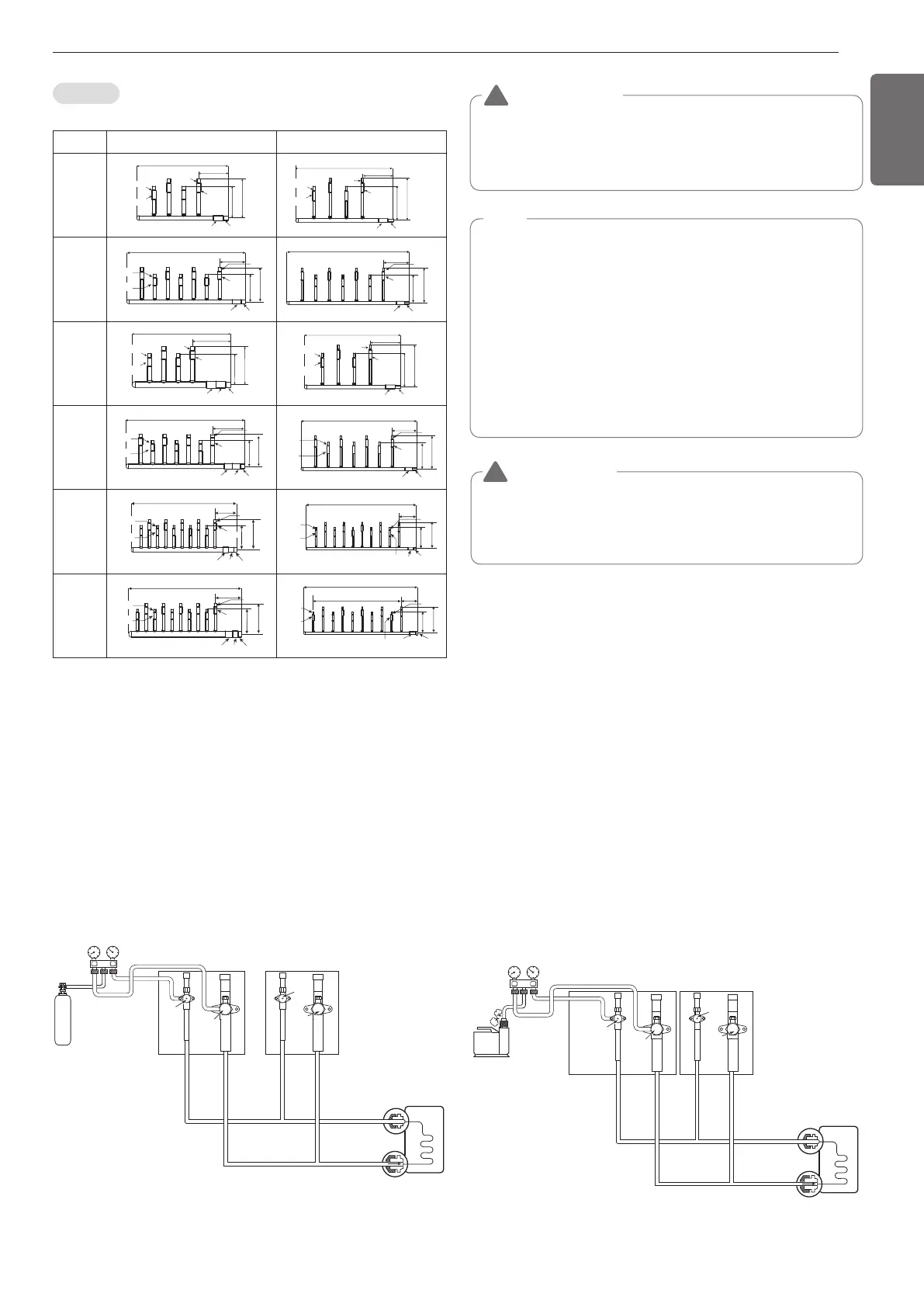

Leak test

Leak test should be made by pressurizing nitrogen gas to 3.8 MPa(38.7

kgf/cm

2

). If the pressure does not drop for 24 hours, the system

passes the test. If the pressure drops, check where the nitrogen leaks.

For the test method, refer to the following figure. (Make a test with

the service valves closed. Be also sure to pressurize liquid pipe, gas

pipe and high/low pressure common pipe)

The test result can be judged good if the pressure has not be reduced

after leaving for about one day after completion of nitrogen gas

pressurization.

For more information, refer accessory installation manual.

Indoor unit

Nitrogen gas

cylinder

Slave 1 outdoor unit Master outdoor unit

Liquide pipe

Gas pipe

Liquide pipe

Gas pipe

Liquid side

Gas side

Close

Close

Close

Close

Header

Models Gas pipe Liquid pipe

4 branch

ARBL054

120

150

360

120

I.D 15.88

I.D 12.7

I.D 12.7

I.D 15.88

I.D 15.88

I.D 19.05

120

120

150

360

I.D 9.52

I.D 6.35

I.D 9.52

I.D 12.7

I.D 9.52

I.D 6.35

7 branch

ARBL057

540

120

150

120

I.D 15.88

I.D 12.7

I.D 15.88

I.D 19.05

I.D 15.88

I.D 12.7

540

120

150

120

I.D 6.35

I.D 9.52

I.D 9.52

I.D 12.7

4 branch

ARBL104

120

150

400

160

I.D 19.05

I.D 15.88

I.D 22.2

I.D 28.58

I.D 25.4

I.D 15.88

I.D 12.7

120

120

150

360

I.D 9.52

I.D 6.35

I.D 9.52

I.D 12.7

I.D 9.52

I.D 6.35

7 branch

ARBL107

120

150

160

580

I.D 19.05

I.D 15.88

I.D 22.2I.D 28.58

I.D 25.4

I.D 15.88

I.D 12.7

120

150

700

120

I.D 6.35

I.D 9.52

I.D 9.52

I.D 6.35

I.D 9.52

I.D 12.7

10 branch

ARBL1010

120

150

160

760

I.D 19.05

I.D 15.88

I.D 22.2

I.D 28.58 I.D 25.4

I.D 15.88

I.D 12.7

120

150

120

720

I.D 6.35

I.D 9.52

I.D 9.52

I.D 6.35

I.D 12.7

I.D 9.52

10 branch

ARBL2010

120

150

182

775

I.D 19.05

I.D 15.88

I.D 28.58

I.D 31.8

I.D 34.9

I.D 15.88

I.D 12.7

120

150

107

60*9=540

700

I.D 6.35

I.D 9.52

I.D 19.05

I.D 15.88

I.D 9.52

I.D 6.35

NOTE

If the ambient temperature differs between the time when pressure is

applied and when the pressure drop is checked, apply the following

correction factor.

There is a pressure change of approximately 0.1 kg/cm

2

(0.01 MPa) for

each 1 °C of temperature difference.

Correction= (Temp. at the time of pressurization – Temp. at the time

of check) X 0.1

For example: Temperature at the time of pressurization

(3.8 MPa) is 27 °C

24 hour later: 3.73 MPa, 20 °C

In this case the pressure drop of 0.07 is because of

temperature drop And hence there is no leakage in pipe

occurred.

To prevent the nitrogen from entering the refrigeration system in

the liquid state, the top of the cylinder must be at higher position

than the bottom when you pressurize the system.

Usually the cylinder is used in a vertical standing position.

WARNING

Use a vacuum pump or Inert(nitrogen) gas when doing leakage test

or air purge. Do not compress air or Oxygen and do not use

Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

!

Vacuum

Vacuum drying should be made from the service port provided on the outdoor

unit’s service valve to the vacuum pump commonly used for liquid pipe, gas

pipe and high/low pressure common pipe. (Make Vacuum from liquid pipe, gas

pipe and high/low pressure common pipe with the service valve closed.)

* Never perform air purging using refrigerant.

• Vacuum drying: Use a vacuum pump that can evacuate to -100.7kPa

(5 Torr, -755 mmHg).

- Evacuate the system from the liquid and gas pipes with a vacuum

pump for over 2 hrs and bring the system to -100.7kPa. After

maintaining system under that condition for over 1 hr, confirm the

vacuum gauge rises. The system may contain moisture or leak.

- Following should be executed if there is a possibility of moisture

remaining inside the pipe.

(Rainwater may enter the pipe during work in the rainy season or

over a long period of time)

After evacuating the system for 2 hrs, give pressure to the system

to 0.05 MPa(vacuum break) with nitrogen gas and then evacuate it

again with the vacuum pump for 1hr to -100.7 kPa(vacuum drying).

If the system cannot be evacuated to -100.7 kPa within 2 hrs,

repeat the steps of vacuum break and its drying. Finally, check if the

vacuum gauge does not rise or not, after maintaining the system in

vacuum for 1 hr.

Scale

Use a graviometer. (One that

can measure down to 0.1 kg). If

you are unable to prepare such a

high-precision gravimeter you

may use a charge cylinder.

Indoor unit

Slave 1 outdoor unit Master outdoor unit

Liquide pipe

Gas pipe

Liquide pipe

Gas pipe

Liquid side

Gas side

Close

Close

Close

Close

Vacuum

pump

Leak Test and Vacuum drying

CAUTION

!

Loading...

Loading...