Do you have a question about the LG MULTI V S ARUN038GSS4 and is the answer not in the manual?

Defines symbols for safety warnings and precautions.

Safety precautions for unit installation procedures.

Further safety guidelines and precautions for installation.

Safety instructions pertaining to electrical wiring and connections.

Safety guidelines and precautions for operating the unit.

Detailed specifications and electrical data for outdoor units.

Information and safety precautions for R410A refrigerant.

Guidelines for selecting an optimal and safe location for the outdoor unit.

Specific safety measures for installation in coastal environments.

Guidelines for performing installations on rooftops.

Precautions for installations in climates with snow and ice.

Methods for securing units and providing lightning protection.

Requirements for unit placement and access for maintenance and service.

Continued requirements for unit placement and service access.

Procedures and safety guidelines for lifting and moving the outdoor unit.

Guidelines for securely attaching the outdoor unit to its base.

Details on foundation requirements and bolt placement for unit mounting.

General guidelines for preparing refrigerant piping for installation.

Procedures for connecting refrigerant piping to the outdoor unit.

Continued guidelines for preparing refrigerant piping.

Proper methods for handling and storing piping materials.

Criteria for choosing appropriate copper tubing for the system.

Information on LG's specific Y-branch and header fittings.

Installation details for Y-branches connecting to indoor units.

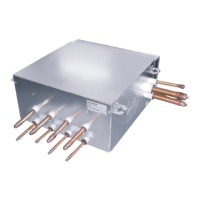

Guidelines for installing header kits for refrigerant distribution.

Managing pipe expansion and contraction due to temperature changes.

Table for calculating linear thermal expansion of copper tubing.

Table for expansion loop dimensions and lengths.

Importance of using only specified pipe sizes to avoid system failure.

Restrictions on adding components to refrigerant piping.

Considerations for using isolation ball valves in the system.

Procedures for routing pipes around obstacles.

Guidelines for properly supporting refrigerant piping to prevent sagging.

Various methods for supporting refrigerant piping.

Procedures for connecting refrigerant piping to the outdoor unit.

Steps to safely open the refrigerant shut off valve.

Steps to safely close the refrigerant shut off valve.

Examples of acceptable refrigerant piping system configurations.

Example of a system configured with Y-branches.

Example of a system configured with a header.

Example of a system using both Y-branches and a header.

Guidance on selecting refrigerant piping sizes for different scenarios.

Table for sizing pipe segments based on capacity and length.

Importance and use of LG's LATS design software for piping.

Various acceptable configurations for refrigerant piping systems.

Details on Y-branch fittings used in refrigerant piping.

Details on header fittings used in refrigerant piping.

Procedure for entering vacuum mode for system preparation.

Step-by-step process for evacuating the refrigerant system.

Procedure for testing the refrigerant system for leaks.

Calculating and adding refrigerant charge to the system.

Continued guidance on calculating and adding refrigerant charge.

Guidelines for properly insulating refrigerant piping.

Table for minimum EPDM insulation wall thickness requirements.

Requirements for pipe sleeves at wall/floor penetrations.

Guidelines for installing refrigerant pipes underground.

How to apply insulation to Y-branch and header fittings.

Basic rules and precautions for electrical wiring installation.

Guidelines for separating power and communication wiring.

How to access and connect power and communication wiring.

Specifics of power and communication wiring terminals.

Details on power supply and wiring requirements.

Requirements for communication cables between units.

Wiring instructions for central controllers.

Wiring instructions for zone controllers.

Wiring for group control of indoor units.

Procedure for performing system self-diagnostics using DIP switches.

Procedure for auto-addressing indoor units to the system.

Continuation of the auto-addressing procedure for indoor units.

Steps to resolve issues with the auto-addressing process.

Procedure for assigning group addresses to connected units.

How to terminate wiring for group-controlled indoor units.

How central control addresses are structured and assigned.

Limits on the number of units connectable to central controllers.

Assigning central control addresses to indoor units.

Steps for powering up indoor unit PCBs.

How to set various system functions via DIP switches.

Procedure to set the cool/heat selection function.

Adjusting fan speed based on static pressure.

Setting fan operation for reduced noise at night.

Assigning a unique address to the outdoor unit.

Setting functions for snow removal and rapid defrost.

Adjusting target pressure settings for heat/cool modes.

Overview of Generation 4 system components and requirements.

Using LG's software for system monitoring and diagnostics.

Further details on LGMV software features and data.

Information on system error codes and their meanings.

List and explanation of error codes for indoor units.

List and explanation of error codes for outdoor units.

Continuation of outdoor unit error codes.

Further outdoor unit error codes.

Safety guidelines regarding refrigerant leaks and concentrations.

Techniques to reduce refrigerant concentration limits.

Checklist for rough-in installation of major components.

Checklist items for piping and insulation installation.

Checklist items for brazing procedures.

Checklist for condensate pump and drain installation.

Checklist items for power and communications cable installation.

Checks for refrigerant circuit preparation before commissioning.

Documents required before initiating system commissioning.

Steps to initiate the commissioning process.

| Brand | LG |

|---|---|

| Model | MULTI V S ARUN038GSS4 |

| Category | Air Conditioner |

| Language | English |