18

MULTI V S System Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Piping Materials and Handling

Pipes used for the refrigerant piping system must include the specified thickness, and the

interior must be clean.

While handling and storing, do not bend or damage the pipes, and take care not to contami-

nate the interior with dust, moisture, etc. See Table 9 for care of piping.

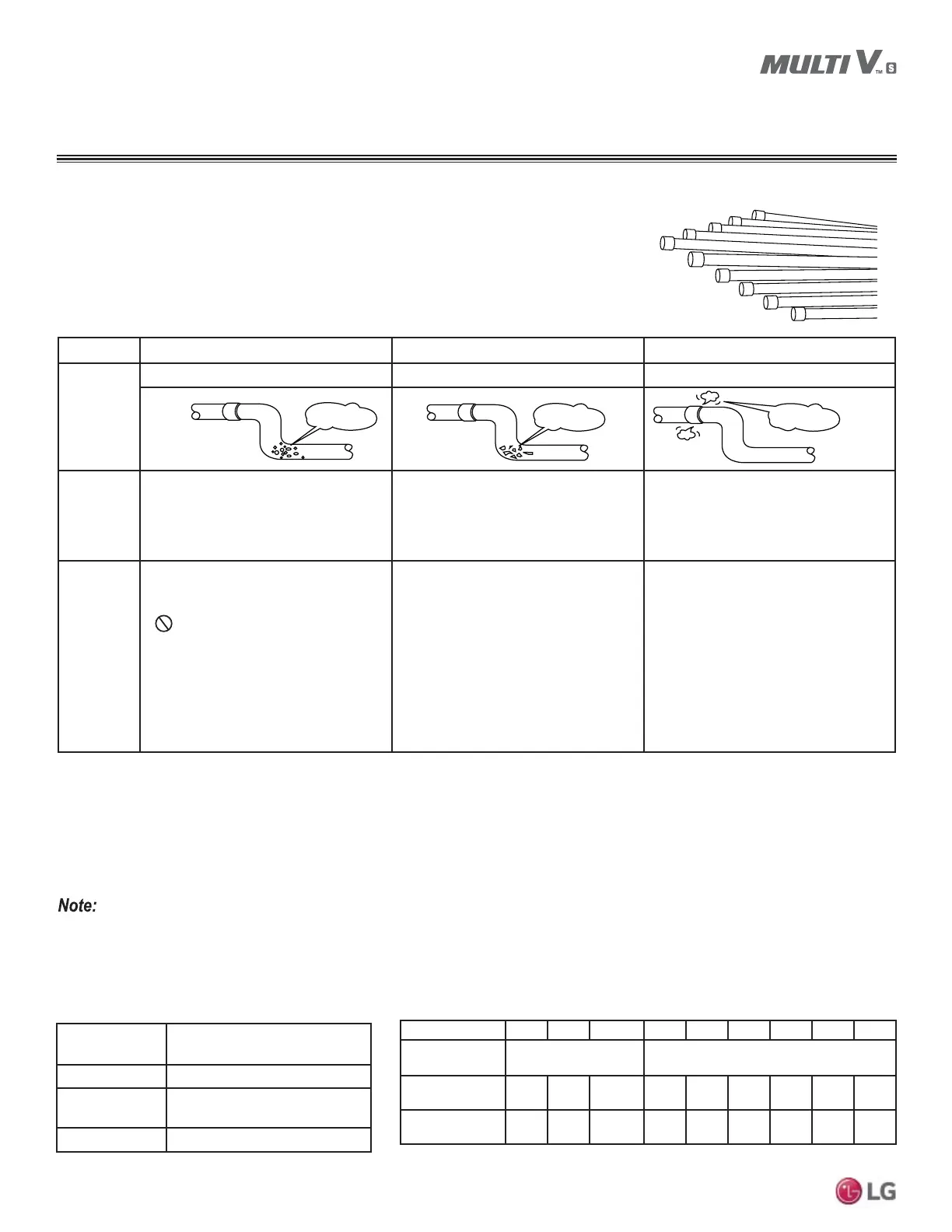

'U\ Clean Airtight

Principles No moisture should be inside the piping. No dust should be inside the piping. No leaks should occur.

Problems

Caused

- Significant hydrolysis of refrigerant oil.

- Refrigerant oil degradation.

- Poor insulation of the compressor.

- System does not operate properly.

- EEVs, capillary tubes are clogged.

- Refrigerant oil degradation.

- Poor insulation of the compressor.

- System does not operate properly.

- EEVs and capillary tubes become

clogged.

- Refrigerant gas leaks / shortages.

- Refrigerant oil degradation.

- Poor insulation of the compressor.

- System does not operate properly.

Solutions

- Remove moisture from the piping.

- Piping ends should remain capped until

connections are complete.

-

Do not install piping on a rainy day.

&RQQHFWSLSLQJSURSHUO\DWWKHXQLW¶VVLGH

- Remove caps only after the piping is

cut, the burrs are removed, and after

passing the piping through the walls.

- Evacuate system to a minimum of 500

microns and ensure the vacuum holds at

that level for 24 hours

- Remove dust from the piping.

- Piping ends should remain capped until

connections are complete.

- Connect piping properly at the side of

the unit.

- Remove caps only after the piping is cut

and burrs are removed.

- Retain the cap on the piping when

passing it through walls, etc.

- Test system for air tightness.

- Perform brazing procedures that comply

with all applicable standards.

- Perform flaring procedures that comply

with all applicable standards.

- Perform flanging procedures that

comply with all applicable standards.

- Ensure that refrigerant lines are pressure

tested to 550 psig.

Moisture

Dust

Leaks

Table 9: Three Principles of Refrigerant Piping.

Figure 21: Keep Piping Capped While Storing.

2'LQ 1/4 3/8 1/2 5/8 3/4 7/8 1-1/8 1-3/8 1-5/8

Material

Rigid or Soft ACR

Rated for R410A

Rigid or Solid ACR Rated for R410A

Min. Bend

5DGLXVLQ

.563 .9375 1.5 2.25 3.0 3.0 3.5 4.0 4.5

Min. Wall

7KLFNQHVVLQ

.031 .031 .031 .039 .042 .045 .050 .050 .05

Table 7: $&55DWHG&RSSHU7XELQJ0DWHULDO

Type

Seamless Phosphorous

Deoxidized

Class UNS C12200 DHP

Straight

Lengths

H58 Temper

Coils O60 Temper

Table 8: ACR Rated Piping Tube Thicknesses.

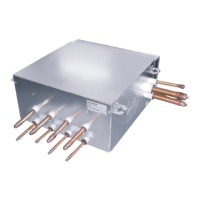

Selecting Field-Supplied Copper Tubing

7\SH$&5FRSSHULVWKHRQO\DSSURYHGUHIULJHUDQWSLSHPDWHULDOIRUXVHZLWK/*0XOWL96DLUFRQGLWLRQLQJSURGXFWV$&5UDWHGWXELQJLVWKH

RQO\W\SHWKDWVKLSVZLWK\HOORZFDSV$SSURYHGWXELQJIRUXVHZLWK0XOWL9SURGXFWVZLOOEHPDUNHG³55$7('´DORQJWKHOHQJWKRIWKH

tube.

• 'UDZQWHPSHUULJLG$&5FRSSHUWXELQJLVDYDLODEOHLQVL]HVWKURXJKLQFKHV$670%FOHDQGU\DQGFDSSHG

• $QQHDOHGWHPSHUVRIW$&5FRSSHUWXELQJLVDYDLODEOHLQVL]HVWKURXJKLQFKHV$670%FOHDQGU\DQGFDSSHG

Tube wall thickness should meet local code requirements and be approved for an operating pressure of 551 psi. If local code does not

VSHFLI\ZDOOWKLFNQHVV/*VXJJHVWVXVLQJWXEHWKLFNQHVVSHUWDEOHEHORZ:KHQEHQGLQJWXELQJWU\WRNHHSWKHQXPEHURIEHQGVWRDPLQLPXPDQG

use the largest radii possible to reduce the equivalent length of installed pipe; also, bending radii greater than ten (10) pipe diameters can minimize

pressure drop. Be sure no traps or sags are present when rolling out soft copper tubing coils.

Piping Preparation

GENERAL INSTALLATION GUIDELINES

Loading...

Loading...