49

This menu is used to perform the zero (or Offset) calibration of the mea-

suring cell.

Depending on the position the SPIN has on the machine, the ZERO point of

the measuring cell may vary due to the actual weight of the cell. To reset the

cell weight, the zero calibration needs to be performed. The zero calibration

process is performed by positioning the SPIN in the desired required work

position, by removing the yarn or any other body possibly coming into con-

tact with the measuring cell and then pressing the “ √ ” button to actuate the

automatic zero calibration (or calibration offset) procedure.

N.B.: The Offset procedure can be simultaneously carried out on all of

the devices if they are linked to the “LGL Pocket” or the “LGL Connect”

in a serial connection, by setting the “Command” parameter to “1”.

WARNING!!!

Prior to performing the zero calibration, ensure that the SPIN is

temperature-stabilised with its surroundings. If necessary,

check temperature again and repeat the zero calibration proce-

dure 15 minutes after power-on, if it has just been removed from

its packing.

In cases when the device remains switched off for a long time (a few days)

and during that time the room temperature has undergone major changes

(changes greater than 8/10°C), it is good rule to switch on the device, let it

reach the required temperature for at least 20 minutes and then perform the

offset calibration procedure before starting the work cycle.

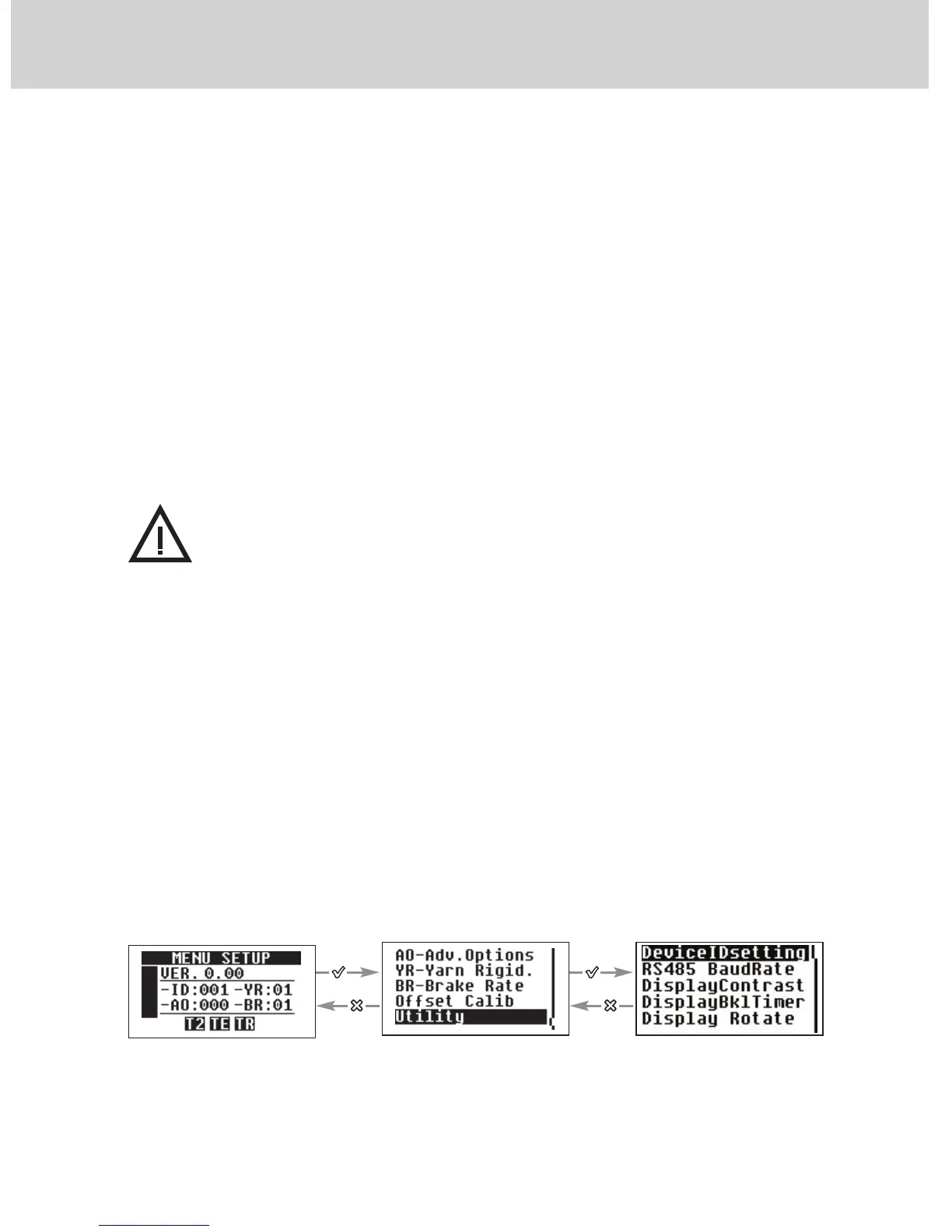

4.2.13 “Utility”

In the “Utility” submenu, a number of settings can be made in connection with

device management, as described in the following paragraphs.

4 - SETTING THE OPERATING PARAMETERS

Use + or - to set the de-

sired value and select by

pressing √

Scroll the parameters by

using + or -

Loading...

Loading...