7

7 --- Maintenance

The Maintenance Programme below must be carried out by a

qualified technician, preferably working under a maintenance

contract.

Before any intervention on the unit or accessing the inner com-

ponents (removing the outer panels), always ensure the ma-

chine is switched off. If the front upper panels are removed (coil

compartment) wait for the fan(s) to come to a complete stop be-

fore accessing the compartment; if the front lower panels are re-

moved, pay special attention when working near the com-

pressor upper part and the discharge line: they are very hot;

possibly wait for them to cool. Be very careful when operating

close to the finned coils,as the fins are very sharp.Do notremove

the fan protection grille before electrically isolating the whole

machine. Do not insert foreign matter through the fan protection

grille. After the maintenance interventions, always close the unit

with the suitable panels, fastened by the tightening system.

7.1 --- Spare parts

The use of original spare parts is recommended.

When placing an order refer to the ”Component List” enclosed

with the machine and quote the unit model no. and serial no.

7.2 --- Dismantling the unit

The machine has been designed and built to ensure continuous

operation.

The working life of some of the main components, such as the

fans and the compressors, depends on the maintenance that

they receive.

If the unit has to be dismantled, the job must be done by skilled

refrigeration technicians.

The refrigerant and the lubricating oil in the circuit must be dis-

posedofinconformitywiththelawsinforceinyourcountry.

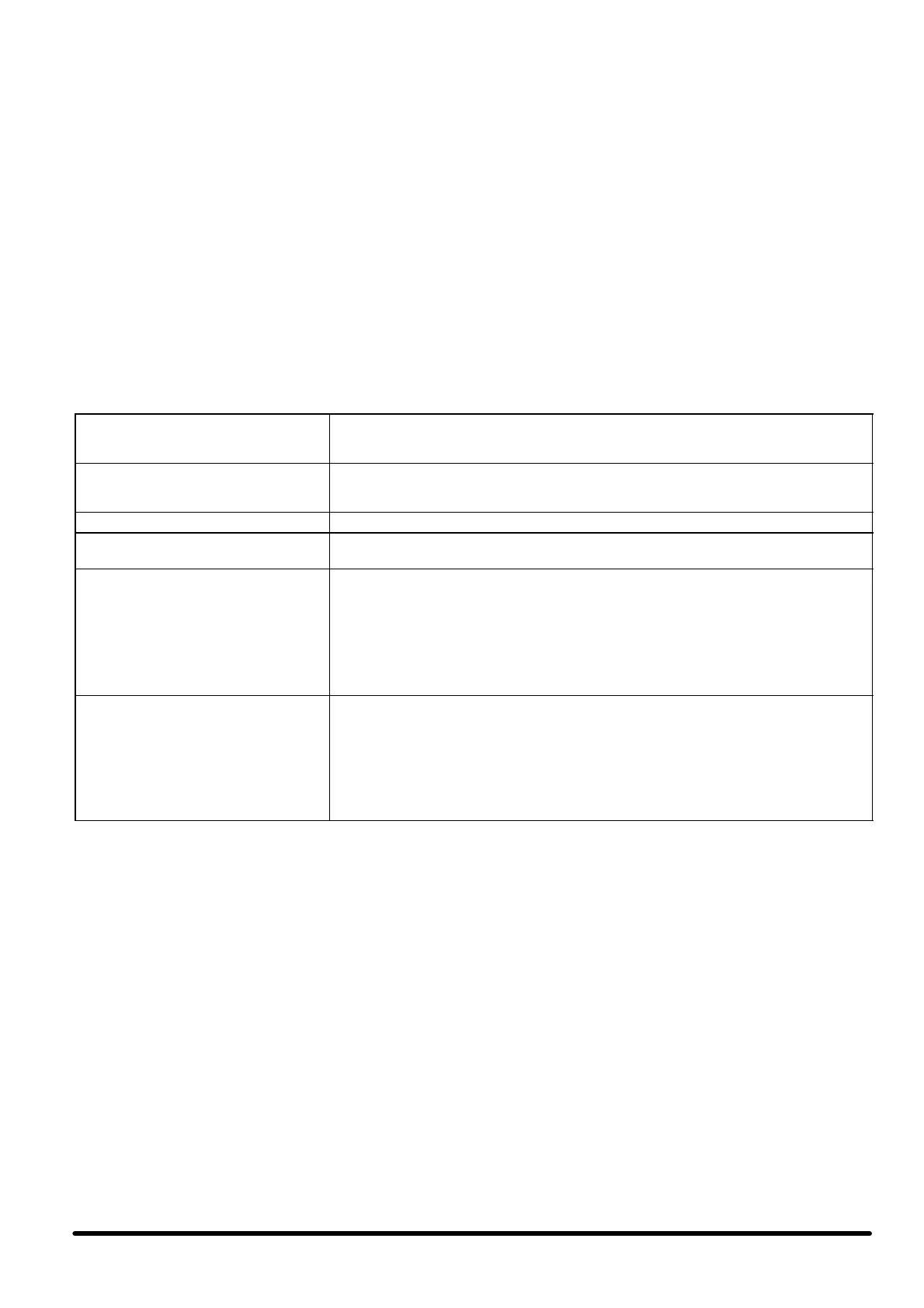

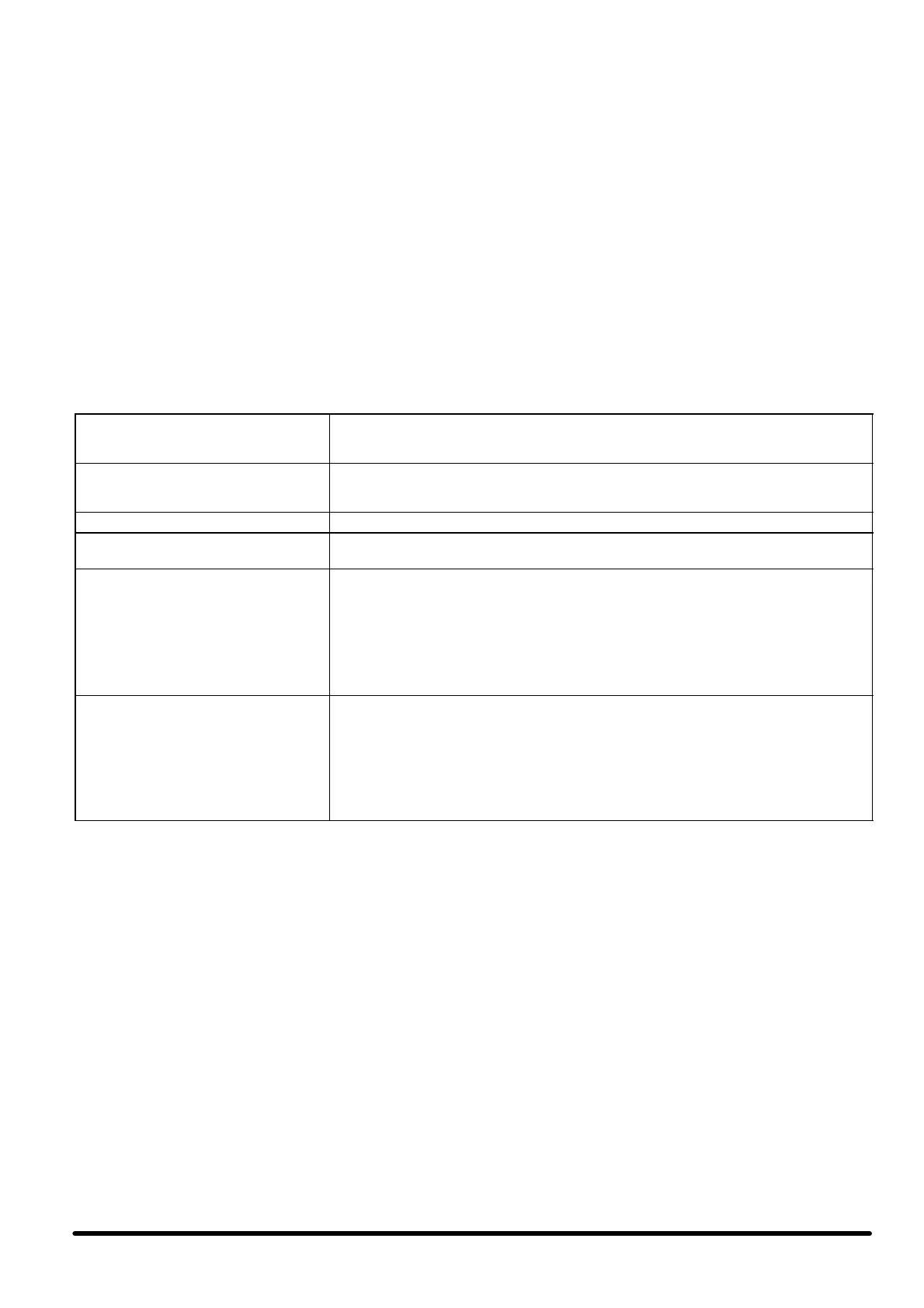

Maintenance programme -- Monthly check

FANS

S Check that the fan motor rotates freely without any abnormal noise, and ensure that the

bearings are not running hot.

S Also check the current absorption.

CONDENSER AND AIR FILTER

S Check the conditions of the filters (if they are supplied); if necessary clean them (including

the electrical panel ventilation filter).

S Check the condenser coils and clean if necessary with compressed air or soft brushes.

CONTROL S Check that the control equipment, L EDs and display are operating correctly.

ELECTRICAL CIRCUIT

S Check the electrical sup ply on all phases.

S Ensure that all electrical connections are tight.

REFRIGERATION CIRCUIT

S Check the condensing and the evaporating p ressures (to be done by a refrigeration techni-

cian).

S Check the compressor’s current absorption, the delivery temperature and possible unusual

noises.

S Check the refrigerant charge by means of the sight glass.

S Check that the safety devices operate correctly .

S Check the correct operation of the thermostatic valve (superheating between 5ûC --- 8ûC).

S Check that the oil level indicated b y the compressor sight glass is higher than the min. value.

CHILLED WATER CIRCUIT

S Ensure that there are no water leaks.

S Bleed any air out of the hydraulic circuit using the bleed valves.

S Verify that the water flow rate is correct.

S Check the inlet --- outlet liquid temperature and pressure.

S Check the correct operation of the three--- way valve (Versions with free--- cooling only).

S Check if the system is charged with the specified g lycol percentage and that no ice has

formed in the hydraulic circuit.

S Check the evaporator cleanliness.

8 --- O p t i o n s a n d A c c e s s o r i e s

8 . 1 --- P u m p s e t

The centrifugal pump units are direct driven, with close---

coupl ed motors and a single shaft; the induction motor has 2

poleswithIP55protectionandclassFinsulation.

Pump casings and impellers are in cast iron EN --- GJL 200, shafts

are in stainle ss steel, the shaft seal is a unbalanced, mechanical

shaft seal with dimensions according to DIN 24 960 and assem-

bly length according to EN 12 756, brass neck ring permits ideal

conditions for the use of water mixtures containing ethylene gly-

col. The pump housing, the motor stool and the motor stator

housing are electrocoated.

The pump units have been chosen and sized to operate within

specific limits, namely:

S Water / ethylene glycol mixtures up to 65% / 35% by weight;

S Temperatures of the standard pumped fluid not lower than

4°C.

The motor stool forms connection between the pump housing

and the motor, and is equipped with a manual air vent screw for

venting of the pump housing and the shaft seal chamber. It is

very important to carry out this operation as the circulation of liq-

uid through theduct of the air vent sc rew ensures lubrication and

cooling of the shaft seal.

Between the outlets of the two chambers and the discharge

flange, twin---head pumps have a non--- return flap valve in

EPDM rubber. The flap is opened by the flow of the pumped liq-

uid and cuts off the port of the idle pump chamber.

In the electrical panel there are automatic circuit breakers for

each pump; the microprocessor control manages the operating

rotation between the two pumps and start ---up of the stand --- by

pump if the primary pump fails.

For the technical features of the pumps and the hydraulic sche-

matic see Tab. 8, Fig. 10 and Fig. 11.

8.2 --- Water chiller with partial heat

recovery (20%)

This option enables the recovery of up to 20% of the heat normal-

ly rejected by the condensers (see Tab. 2). The system does not

require any adjustment and is made up of plate heat exchangers

installed on each circuit before the condenser. The exchangers

are protected by a suitable anti--- frost heater that operates when

Loading...

Loading...