6

TOP---UPS OF UP TO 20---30% OF THE TOTAL AMOUNT OF

OIL CONTAINED IN THE COMPRESSOR CRANKCASE ARE

PERMITTED; FOR LARGER PERCENTAGES CONTACT THE

TECHNICAL SUPPORT DEPARTMENT.

5.2.1 -- Procedure for o il topping--up

If there has been any loss of oil then this must be topped up as

follows:

1) Take a clean, dry, transparent container (with volume cal-

ibrations) and fill it with at least twice the amount of oil re-

quired.

2) Isol ate the compressor by closing the cock on the liquid line.

3) Connect to the fittings on the compressor body (Schraeder

valves) and empty it of refrigerant until atmospheric pres-

sure (1 bar) is reached.

4) Using a pipe, connect t he oil containerto theoil s er vic efitting

on the lower part of the compressor.

5) Open the oil service cock, lifting the co ntainer, so that the oil

flows by gravity.

6) Charge the required quantity of oil (make sure the tube al-

ways remains below the oil level in the container).

7) Stop the oil flow by closing the oil service fitting, open the

shut---off cock on the refrigerating circuit and restore the

drained refrigerant charge.

6 --- Safety Devices Settings

The water chiller has already been tested and set up by the manufacturer. The following setting values are suggested in the field.

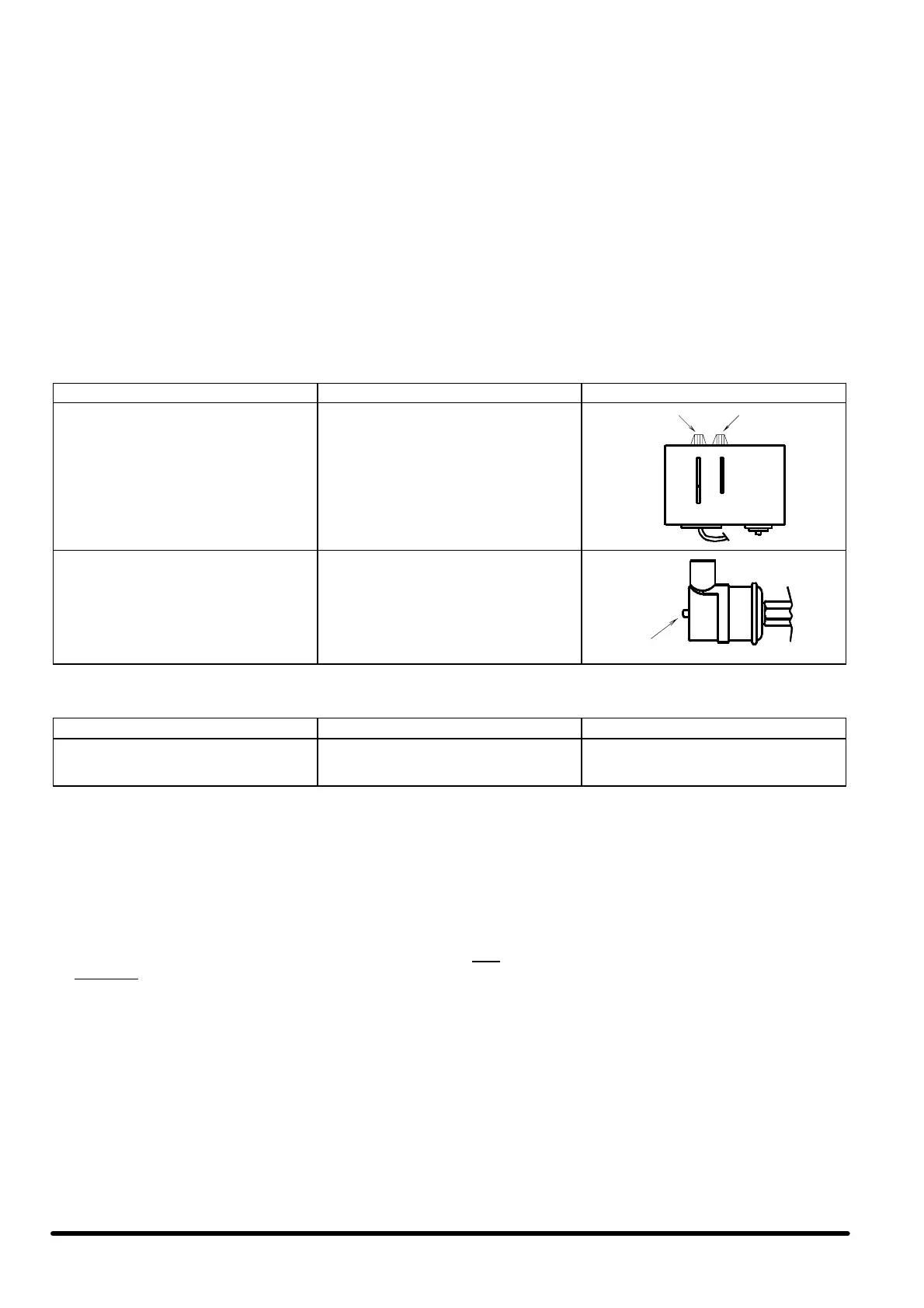

COMPONENT SETTING NOTES

Low pressure switch (LP)

Operation with R407C/R22

(standard factory setting):

START : 3.6 bar

DIFF. : 0.8 bar

STOP : 2.8 bar

bar

5

0.2

1.5

0.5

bar

diff.set

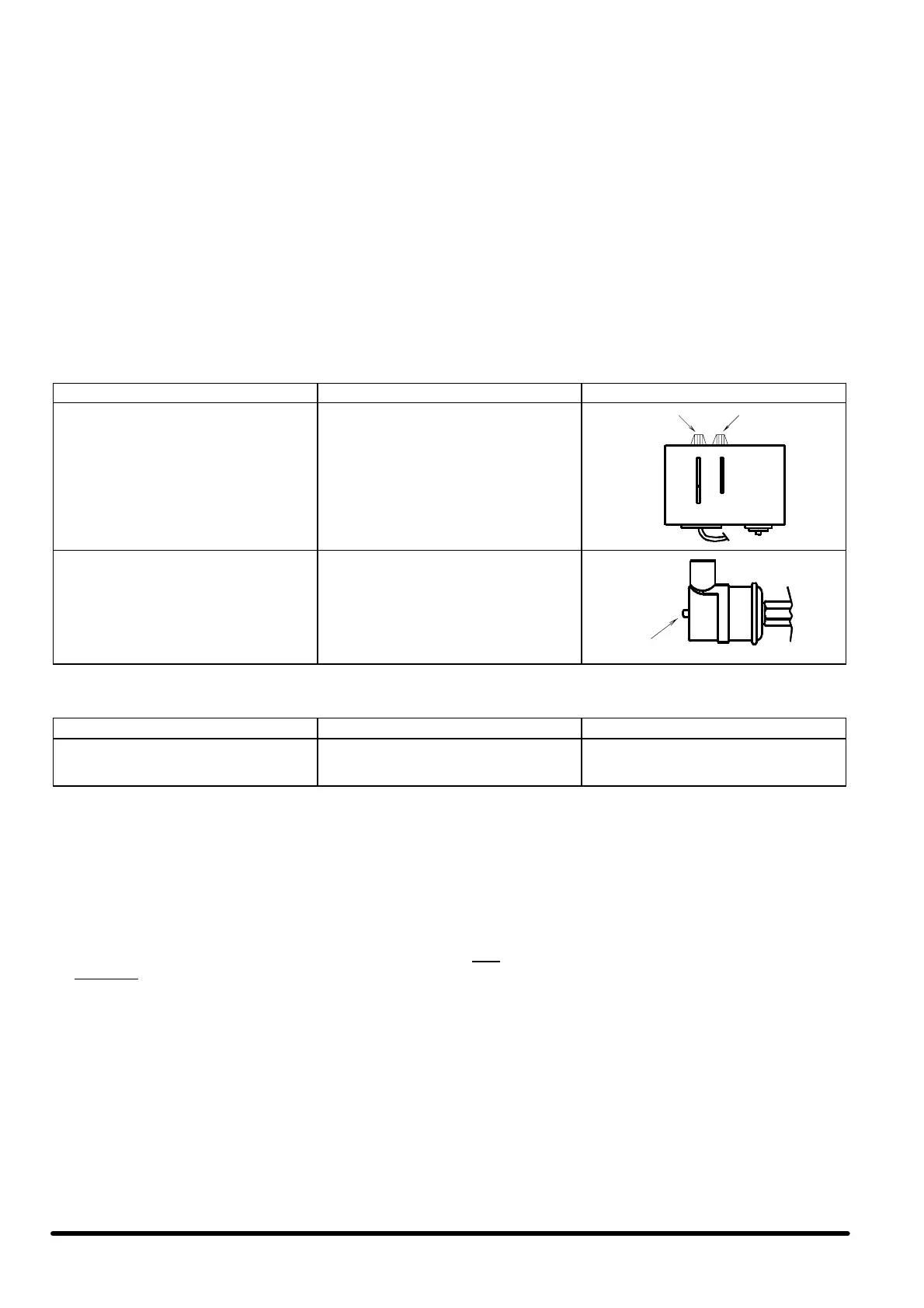

High pressure switch (HP)

Operation with R407C/R22

(standard factory setting):

STOP : 26 bar

START : 20 bar

DIFF. : 6 bar (fixed)

reset

The settings for the safety valves installed on the machine are indicated below:

MODELS SETTINGS SAFETY VALVE

CBH/CLH/CQH 017---020---023---025---028

SBH/SLH 017---020---023---025---028

SQH 017---020---023 ---025

29 bar high pressure side

6.1 --- Setting the rmostatic ex pansion

valve

THIS OPERATION MUST BE PERFORMED BY AN EXPERI-

ENCED REFRIGERATION TECHNICIAN.

Before beginning this adjustment be sure that the refrigerant

charge is correct, checking the the sub ---cooling (3ûC --- 5ûC, as

specified in par. 5.1).

The valve has already been factory --- set and should be reset

when the superheating is not between 5ûC --- 8 ûC, as follows:

1) Important:

Ensure that the instructions in par. 5.1 have been carried out.

2) Allow the compressor to operate for 15 mins.

3) Measur e the superheating as follows:

a) Connect a manometer to the Schraeder connect io n lo-

cated on the evaporator outlet tube, and read the mano-

metric temperature on the scal e for the refrigerant used

(for the units with R407C refer to the pressure gauge

scale indicated with the initials D.P. = Dew Point).

b) Using a cont act thermometer, measure the temperature

on the tube coming out of the evaporator, next to the

socket used for the manometer.

c) The superheating is the difference between the two

readings (b ---a).

4) The superheating must be 5ûC --- 8 ûC; if not, set the expan-

sion valve as follows:

a) Remove the protective cover;

b) Turn the adjustment screw to return to the optimum val-

ues, tightening it in a clockwise directio n to increase the

superheating, or slackening it to reduce the superheat-

ing.

c) Wait about 10 minutes;

d) Measure the superheating and repeat the operation if

necessary.

N.B:

If the superheating is too low, there is a risk of poor lubrication

and consequent breakage of the compressor as a result of pres-

sure shock.

If the superheating is too high the output of the syst em is limited

and the compressor overheats.

Loading...

Loading...