Do you have a question about the Lincoln Electric FineLine 12864 and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

| Model | FineLine 12864 |

| Category | Welding System |

| Language | English |

Essential safety information for operators, observers, maintenance, and proximity personnel.

Warning about chemicals in fumes/gases known to cause birth defects or cancer.

Guidance on protecting skin and eyes from UV radiation produced by plasma cutting.

Precautions to prevent fires caused by sparks, flammable materials, and gas.

Advises on using ear protection due to high noise levels during cutting.

Recommendations for ventilation and breathing equipment to avoid harmful fumes.

Guidelines to minimize exposure to electric/magnetic fields affecting medical devices.

Critical safety precautions to avoid fatal electric shock hazards from high voltages.

Guidelines for safe handling of compressed gas cylinders and preventing explosions.

Lists publications for further info on safety practices for plasma arc cutting.

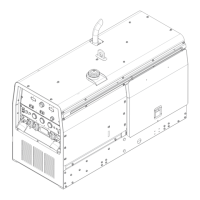

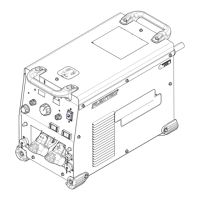

Overview of the FineLine 300HD Plasma System for mechanized cutting.

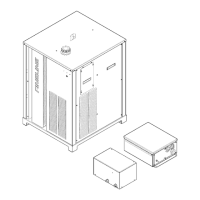

Lists the standard and optional components included with the FineLine 300HD Plasma System.

Information regarding the system's compliance with relevant standards.

Detailed specifications for the FineLine 300HD Power Supply unit.

Information on the cooling system, fluid type, and coolant specifications.

Details on plasma, shield, preflow, and marking gas types and flow rates.

Specifications and physical dimensions for the AGC unit.

Specifications and physical dimensions for the ASC unit.

Specifications, weight, and dimensions for the plasma torch.

Requirements for the HMI and specifications for the console app and server.

Specifications for the required user-supplied Ethernet router/switch.

Chart showing noise levels generated by the system at different distances.

Information on CE marking and compliance with EN 60974-10 for EMC.

Guidelines for positioning the Power Supply, AGC, ASC, and Torch.

Visual guide illustrating how to connect all system components.

Proper grounding techniques to minimize RF/EMI and ensure system immunity.

Instructions for connecting the primary power supply, including voltage selection.

Details on connecting plasma, shield, preflow, and marking gas hoses.

Instructions for connecting electrode lead, work ground, nozzle lead, and coolant hoses.

How to connect torch leads, ASC control cable, and ASC ground cable.

Steps for connecting plasma, shield, and pre/post gas hoses to the AGC.

How to connect the plasma and shield hoses from the AGC to the torch leads.

Connecting various leads, hoses, and fittings to the plasma torch.

Steps for securely mounting the torch handle and clamp to the system.

Step-by-step guide for installing electrode, nozzle, shield, and other consumables.

Instructions for connecting the Power Supply, AGC, and HMI via Ethernet.

How to connect the EStop wiring to the Power Supply terminal block.

Details on the optional CNC interface and its provided I/O signals.

Procedures for installing CutLinc Server and Plasma Console App.

Steps for filling the system with approved coolant and checking for leaks.

A checklist to ensure all installation steps have been completed correctly.

Explanation of status lights and buttons on the Power Supply and Plasma Console.

Step-by-step guide for powering up the system and performing cuts/marks.

Detailed guide on using the Plasma Console App for settings and parameters.

How to access and interpret diagnostic information within the Plasma Console App.

Guidelines and procedures to extend the lifespan of torch consumable parts.

Factors affecting cut quality and how to adjust parameters for best results.

Precautions for piercing thick materials to prevent torch damage.

Methods for starting cuts on thick materials to avoid consumable damage.

Charts to help select the appropriate consumables based on material and amperage.

Detailed instructions for removing and installing torch consumables.

Tables providing starting parameters for cutting various materials and thicknesses.

Monthly tasks for maintaining the Power Supply, AGC, and ASC.

Procedure for replacing the coolant filter cartridge without flushing the system.

Steps for flushing the cooling system and replacing the coolant filter.

Guidelines for inspecting consumables for wear and damage to ensure cut quality.

Procedures for updating the Power Supply, AGC, Plasma Console, and CutLinc Server.

How to interpret error codes displayed by the Power Supply status light.

Lists specific error codes for the Plasma Console and Power Supply with resolutions.

Exploded views and part numbers for the Power Supply assembly.

Exploded view and part list for the AGC unit.

Exploded view and part list for the ASC unit.

Part numbers for the torch handle, clamp, cooling tube, and consumables.

Part numbers and available lengths for various hoses, leads, and cables.

Detailed wiring diagram for the FineLine 300HD Power Supply.

Schematic showing the flow of coolant within the Power Supply.

Wiring diagram for the Automatic Gas Console unit.

Flow diagram illustrating the gas paths within the AGC.

Wiring diagram for the Arc Start Console unit.

Information on EMC compliance and standards for arc welding equipment.

User responsibilities for installing and using the equipment to maintain EMC.

Evaluating the surrounding area for potential electromagnetic problems before installation.

Techniques for reducing electromagnetic emissions from the plasma cutting equipment.

Loading...

Loading...