Do you have a question about the Lincoln Electric RANGER 405D and is the answer not in the manual?

General safety advice for welder operation.

Precautions against electric shock hazards during welding.

Safety measures for welding fumes and gases.

Protection from arc rays and spatter.

Preventing fires and explosions from welding sparks.

Safe handling of compressed gas cylinders.

Safety for electrical and engine equipment.

Explanation of Voltage Reduction Devices and their safety benefits.

Safety considerations for EMF and pacemakers.

Instructions for reducing electromagnetic emissions.

Detailed specs for welding, auxiliary power, and engine.

Initial checks, fuel, oil, coolant, and battery setup.

Key switch, idler, VRD, and panel controls.

Using different welding modes and panel controls.

Guidelines for placement, grounding, and wiring hookups.

Routine checks, oil, filter, air cleaner, cooling, fuel, and battery care.

Solutions for common engine and welding output problems.

Diagnosing and replacing electronic control boards.

Identifying parts via index and illustrated breakdowns.

List and part numbers for optional accessories.

Electrical schematics for troubleshooting and repair.

Terms and conditions of the product warranty.

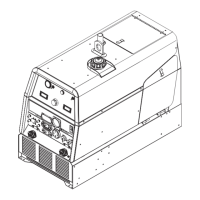

| Brand | Lincoln Electric |

|---|---|

| Model | RANGER 405D |

| Category | Welding System |

| Language | English |

Loading...

Loading...