OPERATOR’S MANUAL

For use with machines having Code Number 10378, 10379, 10539, 10540 and 10550

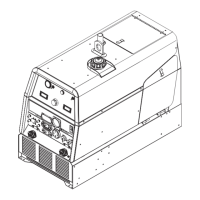

RANGER

TM

9

Multi-Process Gasoline Engine Driven Welder and Power Generator

IM511-D

OCTOBER, 2000

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

Copyright © 2000 Lincoln Global Inc.