Do you have a question about the Lincoln Electric TOMAHAWK 1025 and is the answer not in the manual?

Covers the main warning symbol and the importance of reading manual instructions before operation.

Details hazards related to electrical power, electromagnetic fields, and optical radiation from the arc.

Addresses burn hazards from hot surfaces, equipment weight, cylinder safety, and spark-related fire risks.

Specifies ideal operating location, environmental considerations, and explains the machine's duty cycle.

Details voltage, phase, frequency checks, grounding, and generator compatibility for input power connection.

Explains how to connect the torch, its quick disconnect, and safety features like torch protection.

Covers the work clamp connection and warns about the high open-circuit voltage during operation.

Describes the auto-test function upon startup and the meaning of various status LEDs on the front panel.

Explains the output current knob for setting amperage and the gas purge function for system checks.

Details indicator lights for part-in-place, gas pressure, and cutting mode selection status.

Provides guidance on interpreting error conditions and basic troubleshooting steps.

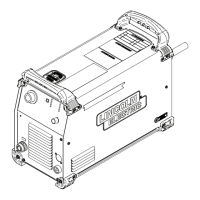

Describes the auto-fan feature and the location of power switch, input cable, and gas inlet connections.

Explains pilot arc initiation, gas flow, preparation, and the steps for executing cutting operations.

Outlines general maintenance tasks like checking cables, connections, and cleaning the torch head.

Provides warnings and instructions for servicing the torch and cleaning the machine enclosure.

Details input voltage, power ratings, and EMC class for the TH1025 and TH1538 models.

Specifies rated output current, voltage, and operational output ranges for both machine models.

Lists requirements for compressed air/gas, recommended input cables/fuses, physical dimensions, and operating temperatures.

| Brand | Lincoln Electric |

|---|---|

| Model | TOMAHAWK 1025 |

| Category | Welding System |

| Language | English |