Page Number - 4

Form 404031

To avoid damaging reel components,

always make sure hose clamp is prop-

erly installed.

Position hose clamp so that approxi-

mately 1/2 loop of hose remains on reel

and latching does not occur when hose

is fully extended.

Slide ball stop over free end of hose

and position slightly below roller outlet.

Tighten screws to secure ball stop to

hose.

Power spring is now set to maximum

tension.

ADJUSTING SPRING

TENSION

To prevent premature power spring fail-

ure, spring tension should be adjusted

so that it requires at least two full turns

of the reel sheave before the spring is

wound tight.

Should less spring tension be desired,

pull hose out from roller outlet to provide

slack and latch reel.

Unwind one loop of hose from reel. Pull

excess hose out through roller outlet and

unlatch reel to retract hose.

Check tension and repeat above proce-

dure until desired tension is

obtained.

Reattach/assemble outboard support to

reel. (See Page 3, Steps 0 thru 0).

ATTACHING CONNECTING

HOSES

To prevent damage to connecting hose

when installing hose to reel, sufficient

clearance must be provided from out-

side edge of sheave.

See Figure (2). Reconnect inlet adapter

to swivel body and replace U-keeper.

Connect other end of connecting hose

to material supply line source or con-

nection.

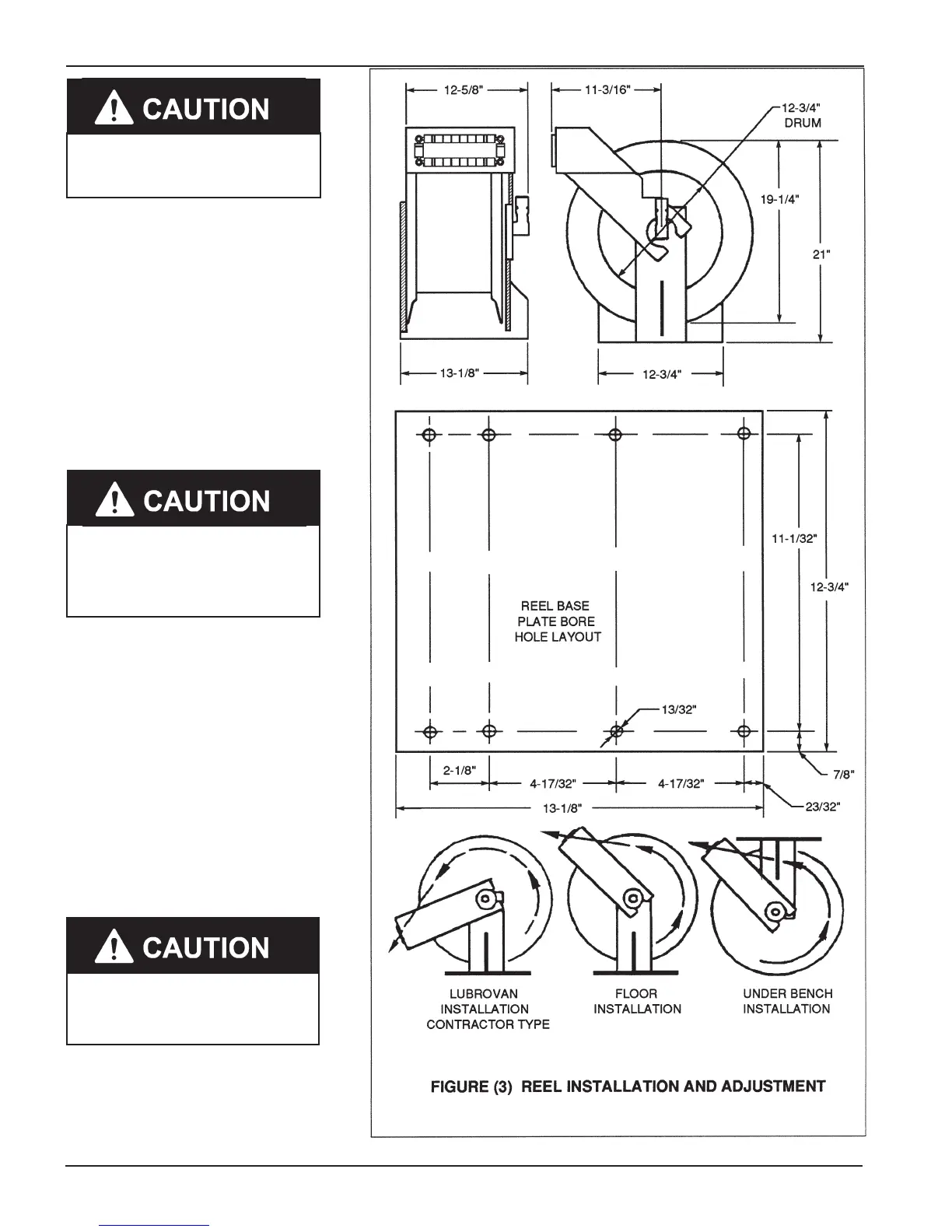

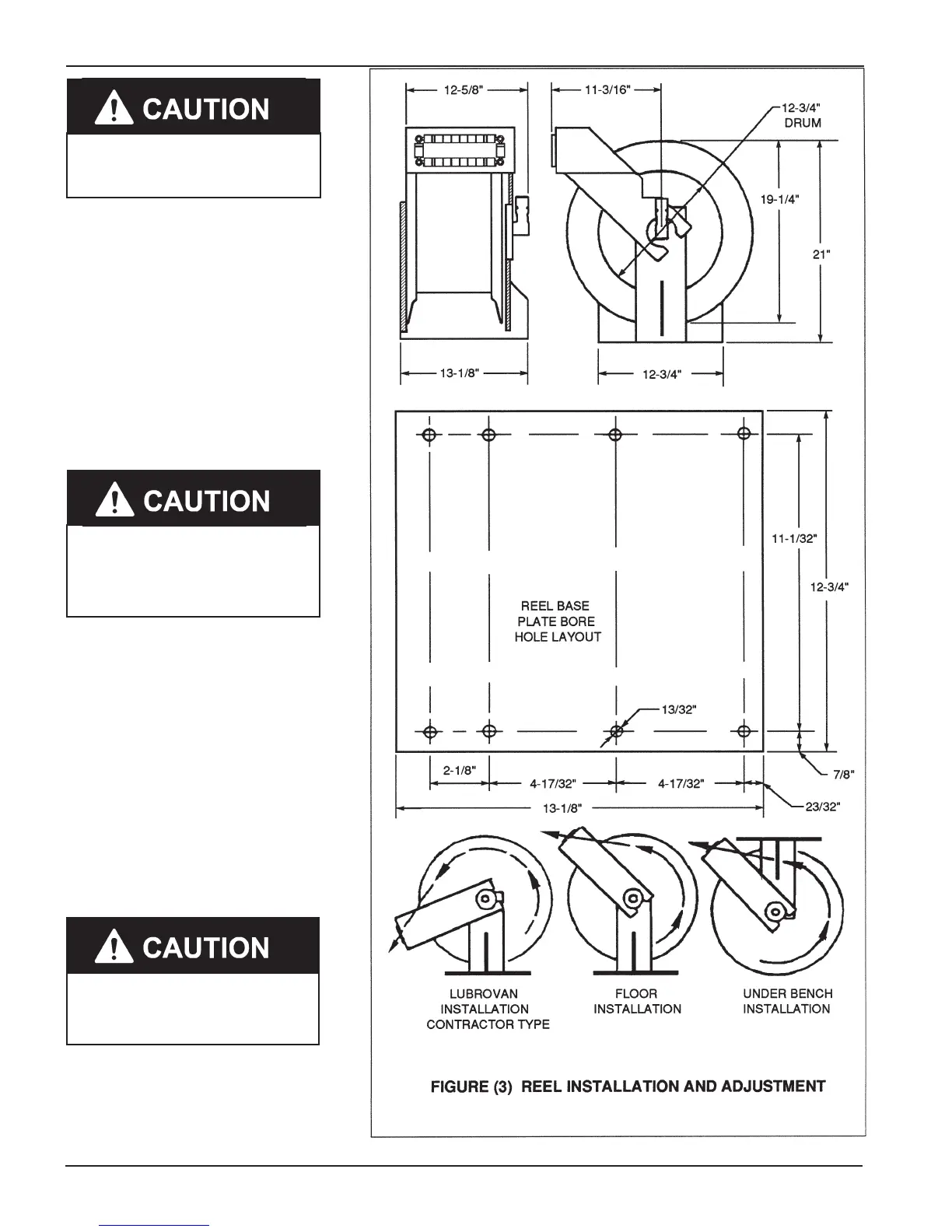

REEL INSTALLATION AND

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Loading...

Loading...