9

Cleaning and maintenance of your machine

The most expensive part of a laminator is usually the rollers, if these become

damaged they are costly to repair. Always ensure you look after the rollers and

clean them regularly to avoid a build up of glue (see advice below). Never hold

a sharp object such as a knife close to the rollers in case of catching the rubber

as this could cause permanent damage that will effect the result of your work.

When your laminator is cooling down, always separate the rollers using the roller

pressure knob, this will ensure that your rollers do not touch when still hot as

this could leave a ‘at spot’.

Cleaning the rollers

It is easier to remove adhesive from the rollers when they are warm, do not

attempt this if the machine is hot (above 40

o

C). For easy access, remove the

safety shield and feed tray. Always use a clean cloth and a mild anti-static foam

cleaner such as Amberclens by Ambersil or similar, do not use a heavy duty

solvent or anything abrasive.

If the lm becomes jammed in the machine in any way and there is a large build

up of adhesive, do not try and remove this yourself, contact your supplier for

advice.

Troubleshooting

My laminator has no power

Make sure that the electrical outlet being used is not damaged and that it is supplying power. Ensure the power cord

is rmly tted in the back of the machine and not straining in any way. If all of this seems correct, there are three

fuses to check, one is located next to the power switch, the other two are located underneath the laminator.

Contact your supplier if none of these solutions resolve the problem.

My lamination is coming out cloudy

This means that the temperature is not hot enough, try and increase by 5

o

C and wait until the laminator has reached

the new temperature before putting through another print.

My lamination has come out wrinkled/creased

This means that the temperature is too hot. You should also put a test document through rst to avoid ruining your

work. Reduce the temperature by 5

o

C and wait until the laminator has cooled before trying again.

The lm is wrapping around the rollers when I try to laminate

The lm may be threaded incorrectly, refer to the threading diagram on page 6 or 8 (depending on if you are doing

single sided or encapsulating. The adhesive side of the lm may be facing the roller. Stop the operation, wait until

the laminator has cooled down and thread the lm again in the correct manner.

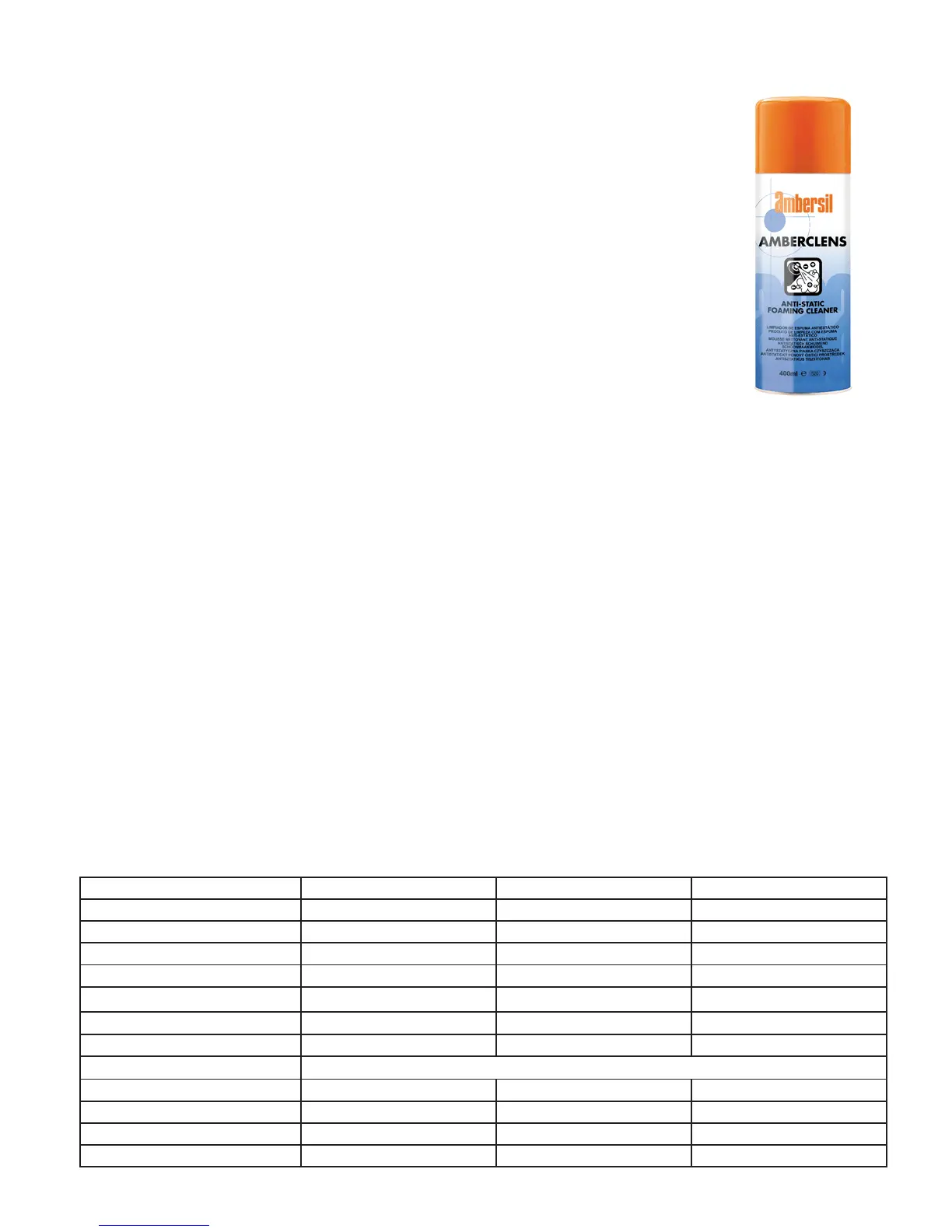

Specication chart

MODEL DH-360 DH-460 DH-650

MAX LAMINATING WIDTH 340mm 460mm 650mm

MAX LAMINATING THICKNESS 5mm 5mm 5mm

MAX LAMINATING TEMPERATURE 140

o

C 140

o

C 140

o

C

MAX LAMINATING SPEED 1.4m/min 1.4m metres/minute 1.4 metres/minute

RECOMMENDED FILM BOSS lm, up to 250 micron BOSS lm, up to 250 micron BOSS lm, up to 250 micron

DIAMETER OF HEATING ROLLER 44mm 55mm 55mm

DIAMETER OF PULL ROLLER 30mm 45mm 45mm

POWER SUPPLY 100, 110, 220-240V, 50, 60Hz

POWER 700W 950W 1600W

DIMENSIONS 620 x 420 x 310mm 720 x 520 x 400mm 910 x 520 x 400mm

WEIGHT 30kg 45kg 58kg

STAND N/A N/A Optional Extra

Loading...

Loading...