3

6. TROUBLE SHOOTING GUIDE

7. HCV TEST PROCEDURE

7.1

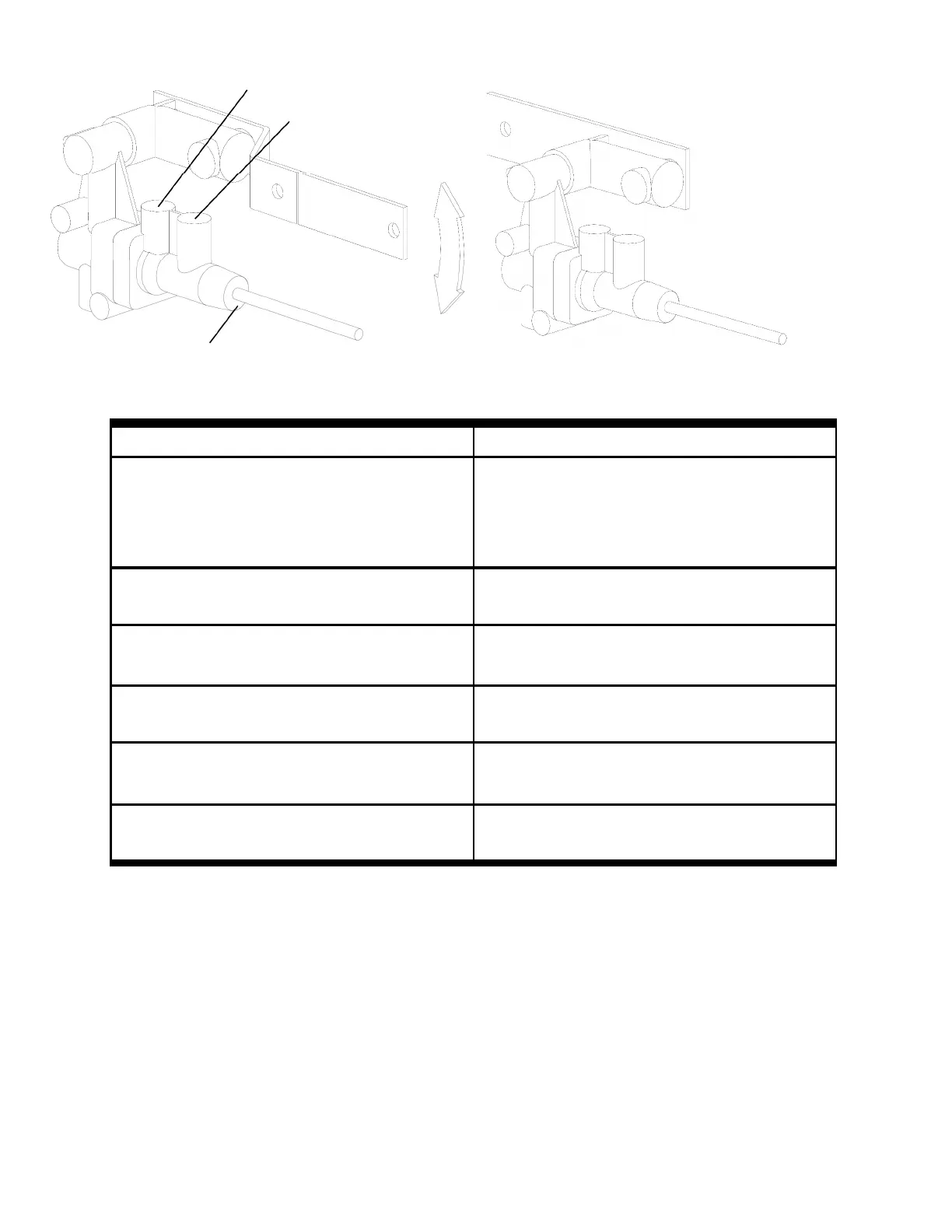

With a minimum of 90 psi at the supply port, rotate the

lever up (as indicated on the side of the valve) 30

°

to

45

°

. Air should begin to flow into the air springs within

seconds.

7.2

Rotate the lever to the neutral position. Air flow should

stop.

7.3

Rotate the lever down 30

°

to 45°. Air should begin to

exhaust from the air springs within seconds.

TO AIR SPRINGS

AIR SUPPLY

EXHAUST PORT

FILL

EXHAUST

Figure 1. Typical Chassis Configuration

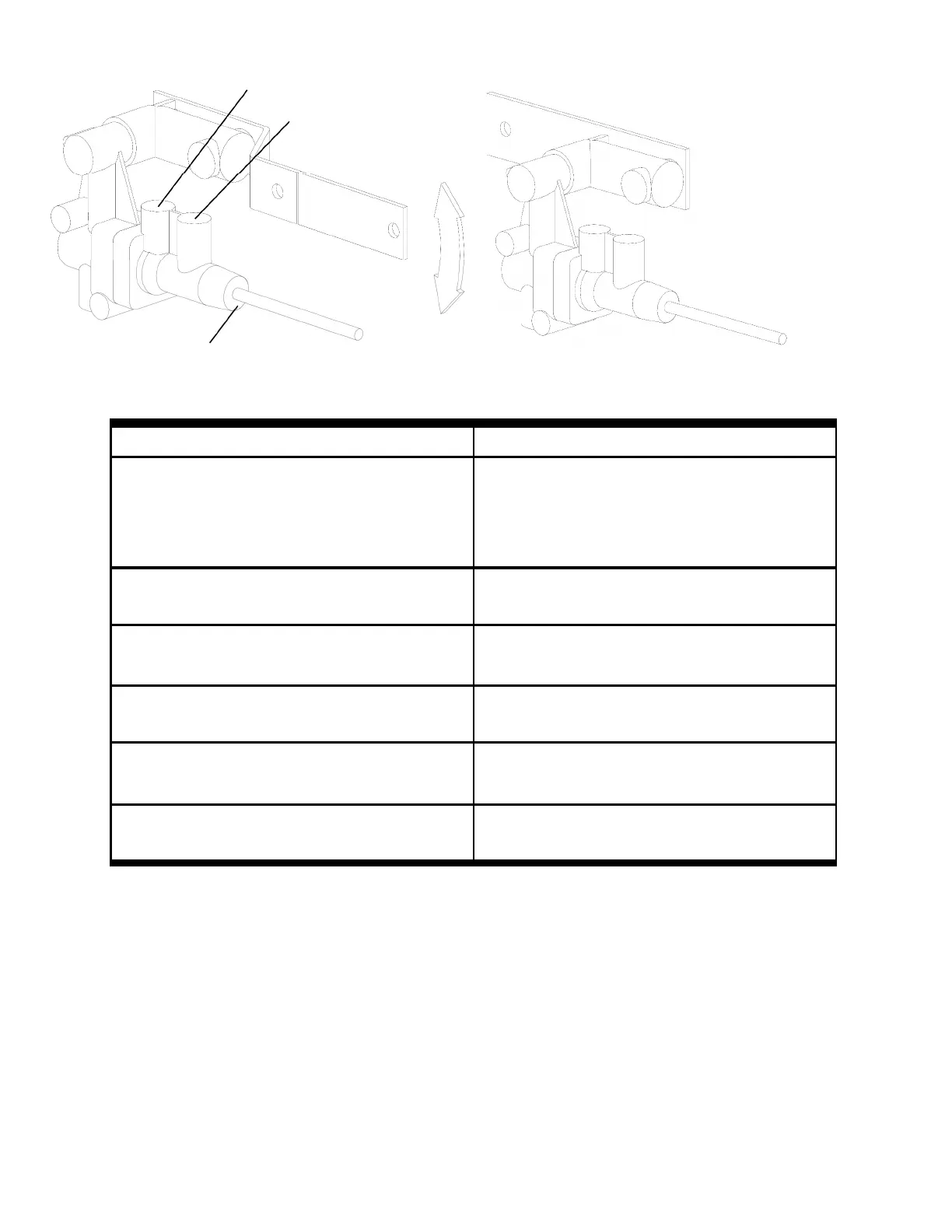

Figure 2. Typical Cab Configuration

PROBLEM POSSIBLE CAUSE

Air springs flat

Obstruction in air line

Insufficient air pressure to suspension

Defective Pressure Protection Valve

Defective HCV-see test procedure

Air leak in system

Air Springs raise to full height but do not exhaust

Obstructed air line

Defective HCV-see test procedure

Air springs deflate when parked

Leak in air system-check with soapy water

Defective HCV-see test procedure

Suspension will not maintain proper height

Obstructed air line

Defective HCV-see test procedure

Hard ride

Ride height out of adjustment-readjust per vehicle

service manual

Cab suspension overshoots center

Replace shocks

Use short delay H00450 HCV

7.4

Rotate the lever to the neutral position. Air flow should

stop.

7.5

If the valve fails to flow air or shut off as specified, re-

place with a new one.

8. REASONS TO REPLACE THE HCV

8.1

• HCV did not pass the test procedure

• Air leaks from the HCV

• HCV is damaged

Loading...

Loading...