Installation & Operation Manual

5 Hydronic piping (continued)

It is required that boiler piping systems

utilize Primary/Secondary or Fixed or

Variable Flow Primary configurations as

shown in FIG.’s 5-2 thru 5-5. The use of

other boiler piping configurations could

result in improper building and system flow

rates leading to inadvertent boiler high limit

shutdowns and poor system performance.

NOTICE

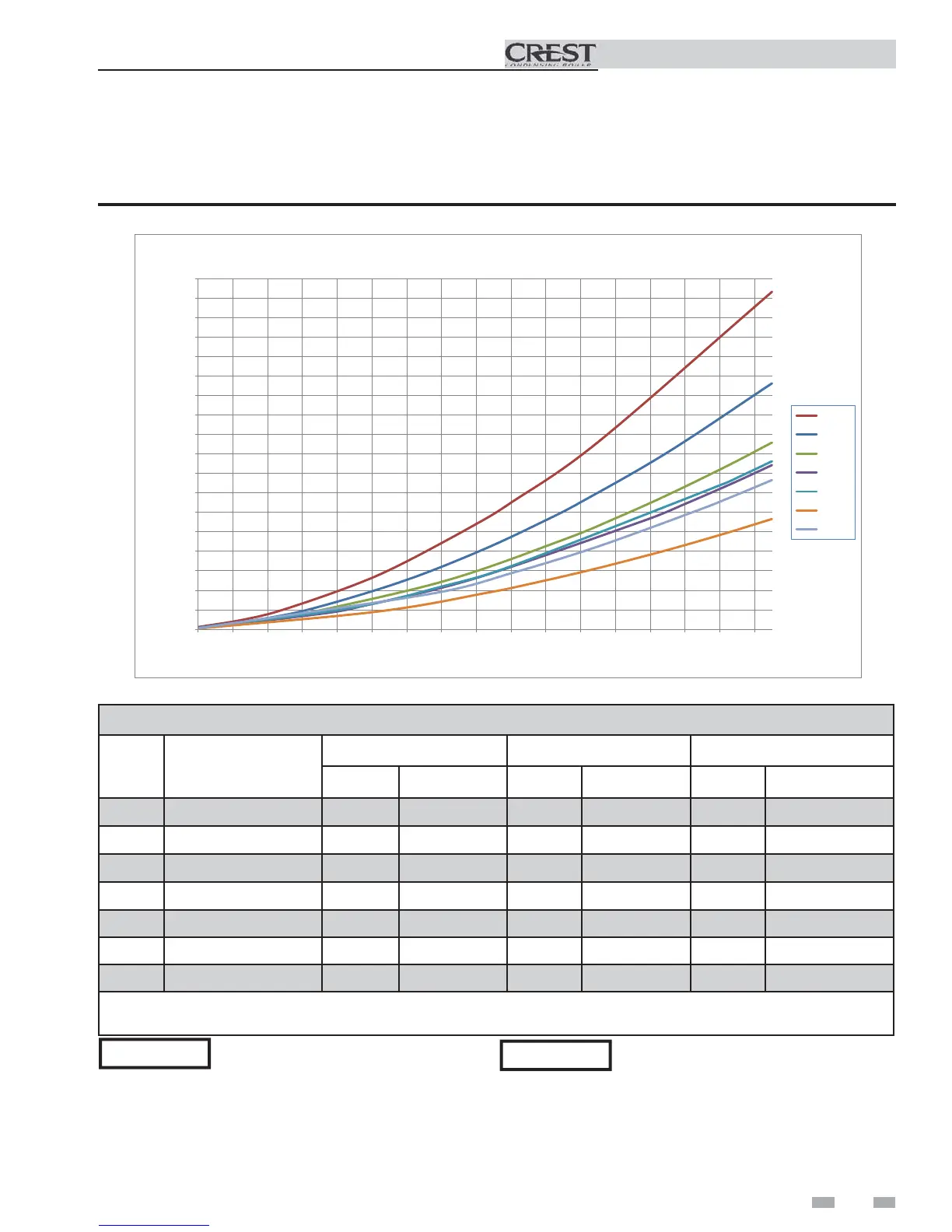

The pressure drop reflected in FIG. 5-1 is

for the boiler only. Additional allowances

must be made for piping, especially if

sizing pumps for Primary/Secondary

applications.

NOTICE

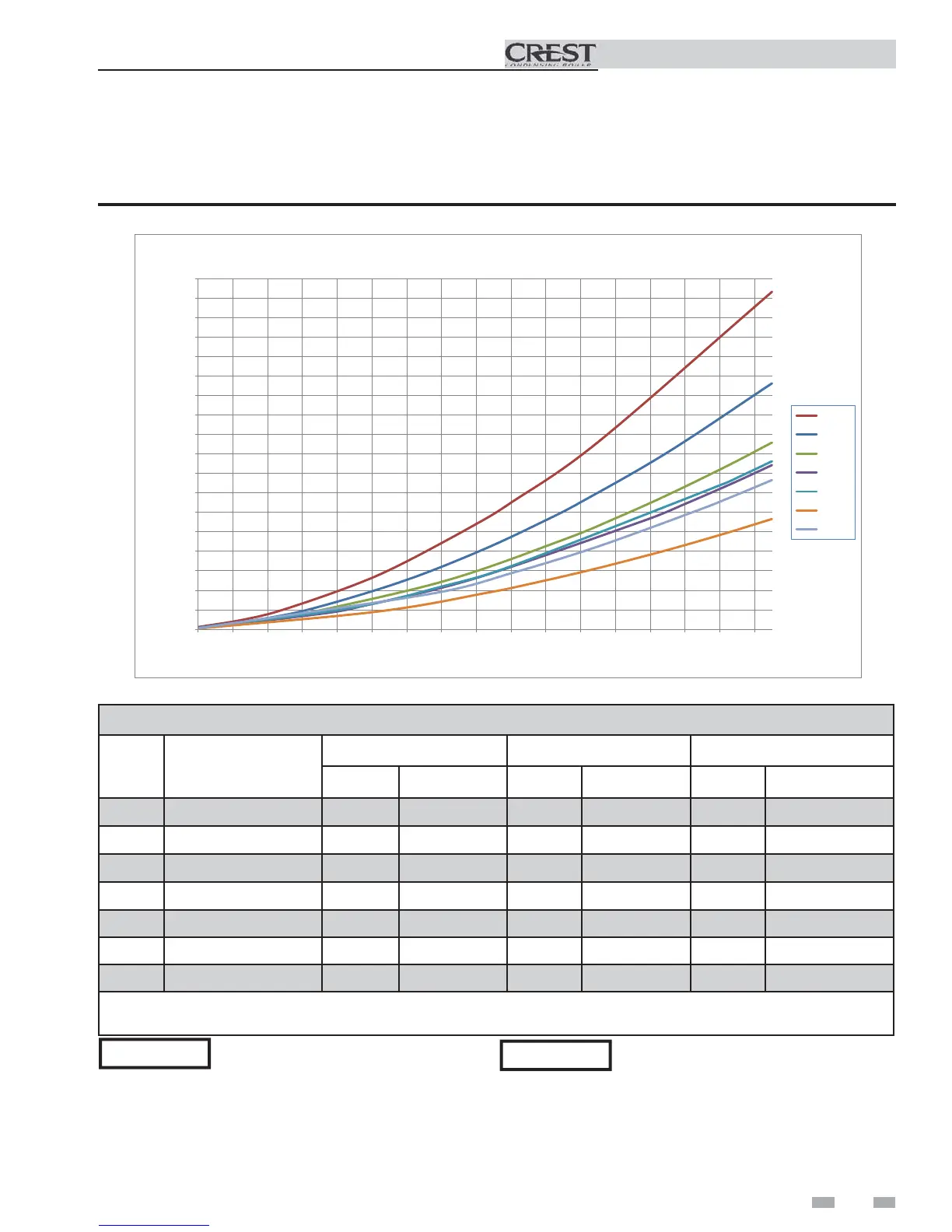

TEMPERATURE RISE APPLICATIONS

Model

BOILER

CONNECTION SIZE

20°F 40°F 60°F

GPM FT/HD GPM FT/HD GPM FT/HD

FB 1500 4" 138 3.4 69 1.0 46 0.5

FB 2000 4" 184 4.1 92 1.2 61 0.6

FB 2500 4" 230 4.6 115 1.4 77 0.7

FB 3000 4" 276 5.6 138 1.7 92 0.8

FB 3500 4" 322 7.5 161 2.2 107 1.1

FB 4000 4" 248* 4.2 186 1.8 124 0.9

FB 5000 4" 310* 4.5 233 0.9 155 0.5

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

17.00

18.00

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340

Pressure Drop (Feet of Head)

Flow Rate (GPM)

CREST Pressure Drop Curve

FB1500

FB2000

FB2500

FB3000

FB3500

FB4000

FB5000

Figure 5-1 Pressure Drop vs. Flow

Table 5A Sizing Information for Temperature Rise Applications_20°F, 40°F and 60°F

25

Circulator sizing

The Crest heat exchanger does have a pressure drop, which must be considered in your system design. Refer to the graph in

FIG. 5-1 for pressure drop through the Crest heat exchanger.

[Models FB 1500 - 3500 based on 92% AHRI Effi ciency and Models FB 4000 - 5000 based on 93% Effi ciency]

*Flow is based on 30°FT.

Loading...

Loading...