9

2.2 Checking the battery

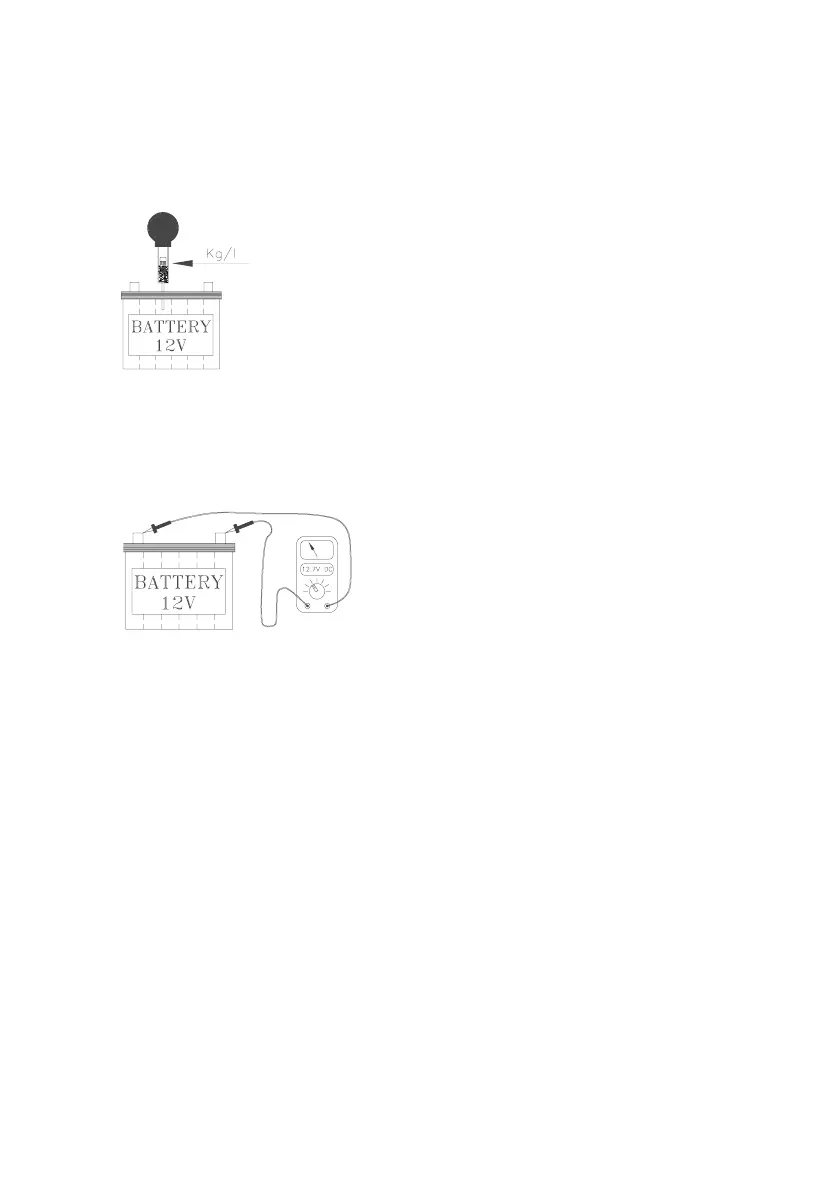

Method A for SEMI-TRAK and TUBULAR CELL:

Check acid density in the six battery cells with an acidometer.

Check each cell - max. difference between each cell 0.04 kg/l.

Method B for all three battery types:

To measure the voltage, use a digital voltmeter (DC) on the battery poles. The truck

must not have been in use for the previous 30 minutes.

DENSITY

1.26 - 1.28 kg/l Fully charged

1.19 - 1.20 kg/l 1/2 charged

1.16 - 1.17 kg/l 1/4 charged

1.10 - 1.11 kg/l Discharged

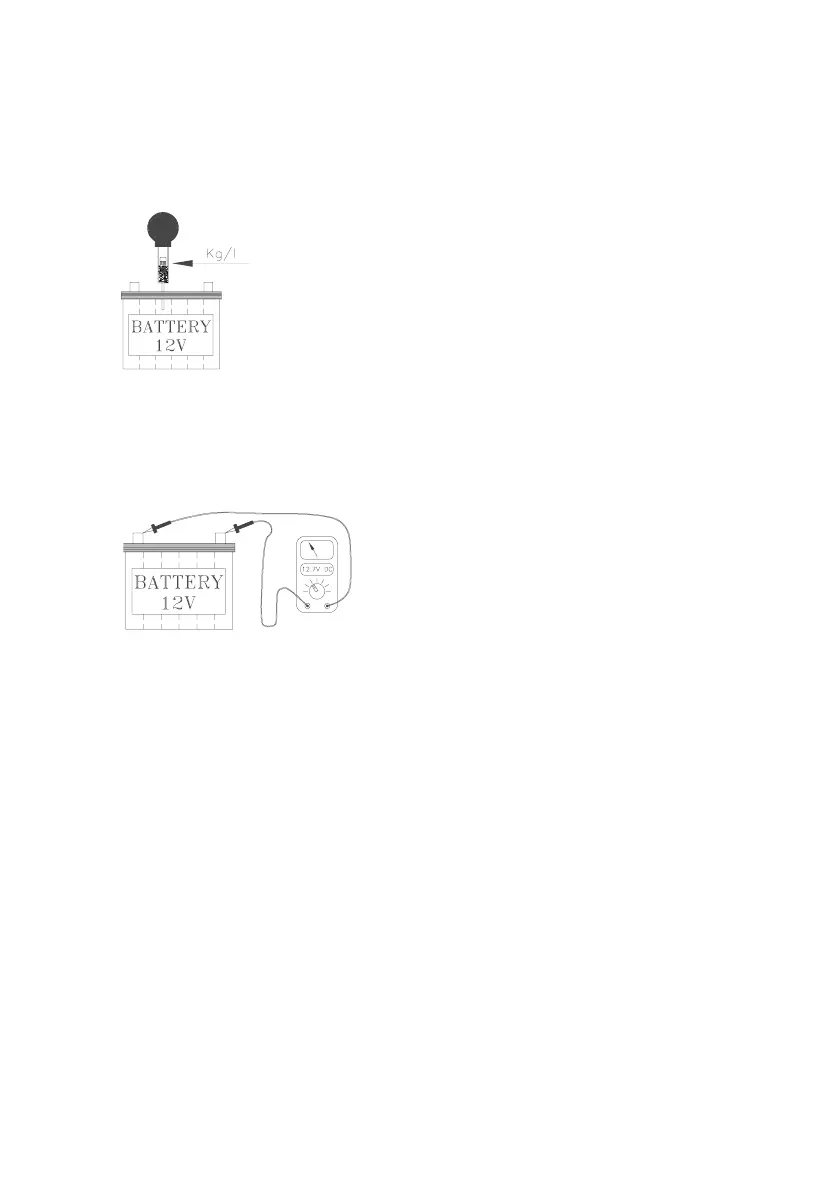

2.3 Battery charging

Charging must be performed with a charger correctly set with the charging voltage for

the battery type, see point 2.1. For connection and operation, see the instructions

accompanying the charger. The manufacturer recommends a charger of 20 amp

capacity. During charging, the temperature in the battery must not

exceed 50°C.Charging simultaneously with truck operation is not advised.

2.4 Warnings and information on battery

Avoid the use of naked flame in the vicinity of tubular cell and SemiTrak batteries. The

charging of tubular cell and Semi-Trak batteries gives off gases that can be explosive.

Therefore charging should be performed in a ventilated room. At temperatures around

freezing point, battery capacity is reduced by 30%.

Approx. 12.7 V Fully charged

Approx. 12.2 V 1/2 charged

Approx. 12.0 V 1/4 charged

Approx. 11.6 V Discharged

Loading...

Loading...