Maintenance

The electric saw is simple to take care of. The maintenance required is listed below. Be sure the machine is vol-

tage-free before you take it from the guide rail or do any work in the vicinity of moving parts.

- Make sure that there is always chain oil in the container when sawing.

- Remove chips and lings that may be stuck in the chip ejector.

- Make sure there are no chips between the spacers and the bar during assembly.

- Check that the feed line runs correctly around the pulley and onto the line winder.

- Chips can ll the line hole at the gear housing. This can be prevented by making a simple knot in the line at the

logdog. This knot will then clean the hole out at each cut.

- It is important that the line and winder function easily so that the saw can be pulled back smoothly. Lubricate the

plastic gears with silicon spray.

- Make sure the slide does not get clogged with chips. If needed, clean it out with a at screw driver. You should

also lubricate the sliding rails with silicon spray or something similar.

- While the E 5000 can stand rain and moisture, if you aren’t using the saw, it should be covered over or kept in-

doors.

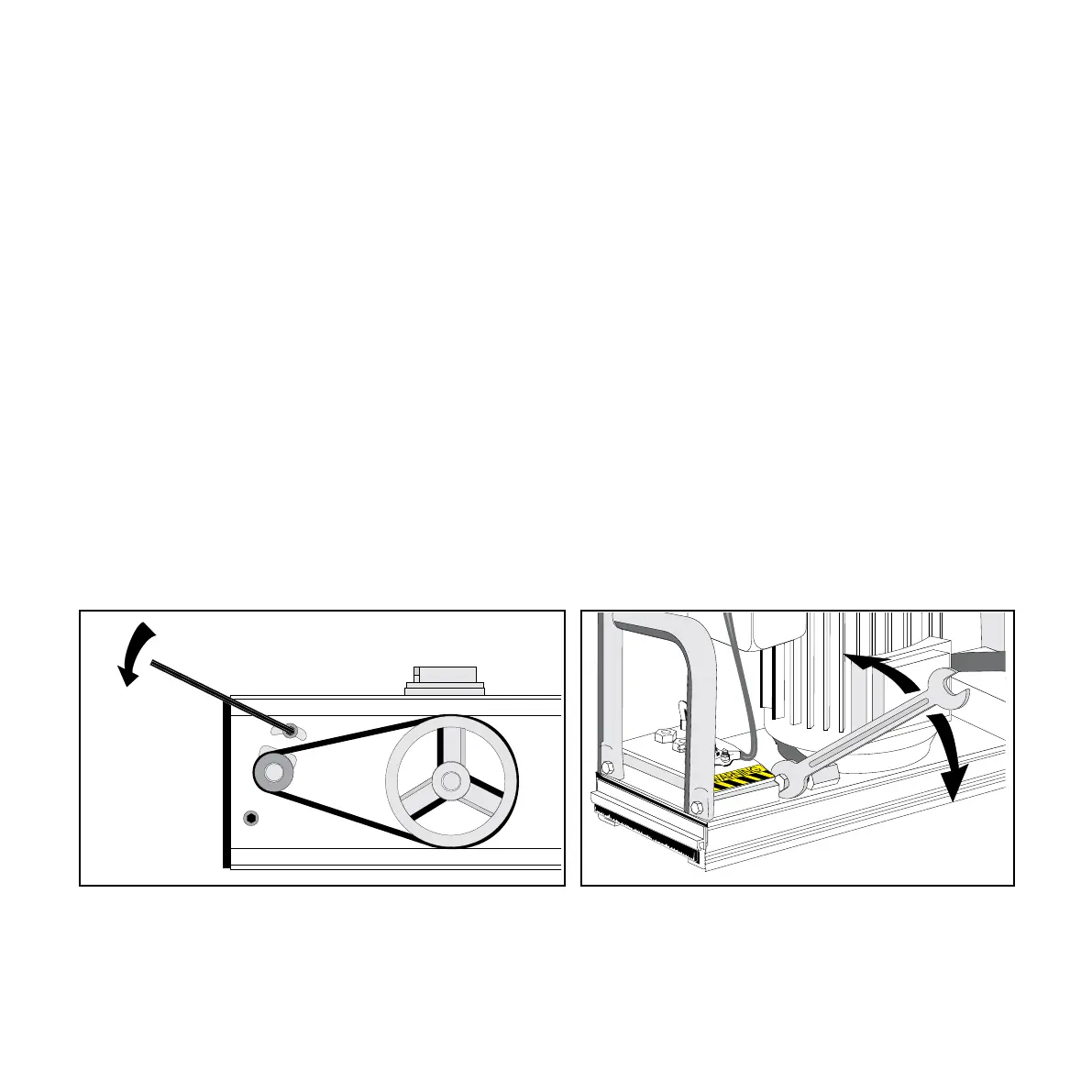

Belt tension

Tighten

Loosen

7

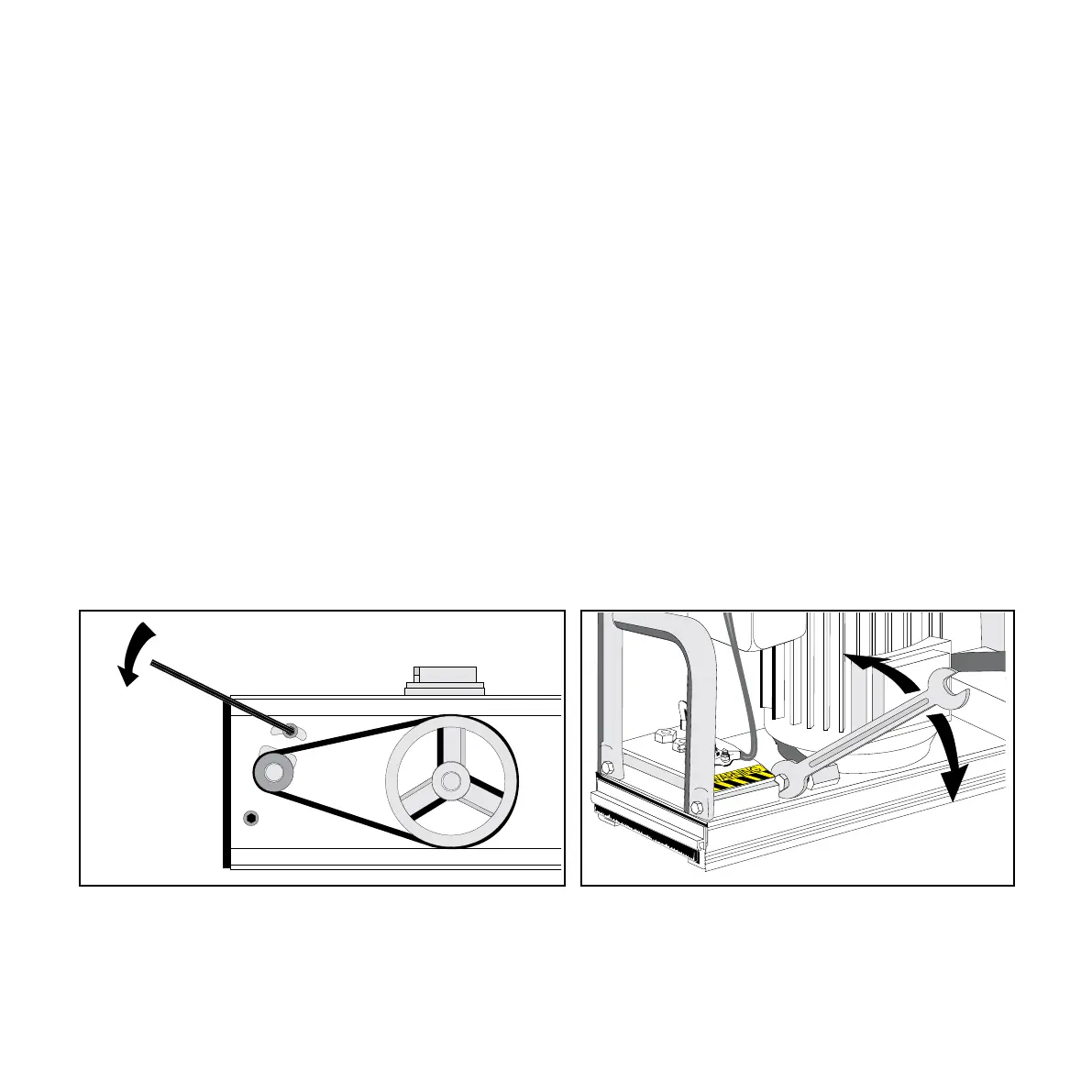

Instructions: Tip the saw on its side and loosen the gear

bolts on the underside. Use a 6 mm hex-wrench to loosen

them about one turn. Then adjust the belt tension using

the setting bolt resting against the gear housing. Finish by

retightening the gear bolts well.

Under normal use, the Poly V-belt should last for may

years. However, after some use, it may need to be ten-

sioned in order to prevent slipping under use. For the

longest working life possible, the belt should be tighte-

ned only until it engages.

Loading...

Loading...