Select pump head

and tubing refer to

thetableofpage4

External Control Input

Analog Signal Input function

Communication Control

The pump can connect to control computer (computer, PLC, SCM) through

RS485 serial communication module (shown as below). Please contact Longer

Company for communication protocol.

COM

B

A

11 12

Set the “External Control” in “on” state. External Control Module is shown as below.

Note:

Five kinds of standard external control module need to be ordered separately

according to special requirements.

5

4

3

2

1

External Control Module

Analog Control

4 - 20 mA Speed Control

0-5VSpeed Control

0 - 10 V Speed Control

0 10 KHz Speed Control-

External Control

DB15

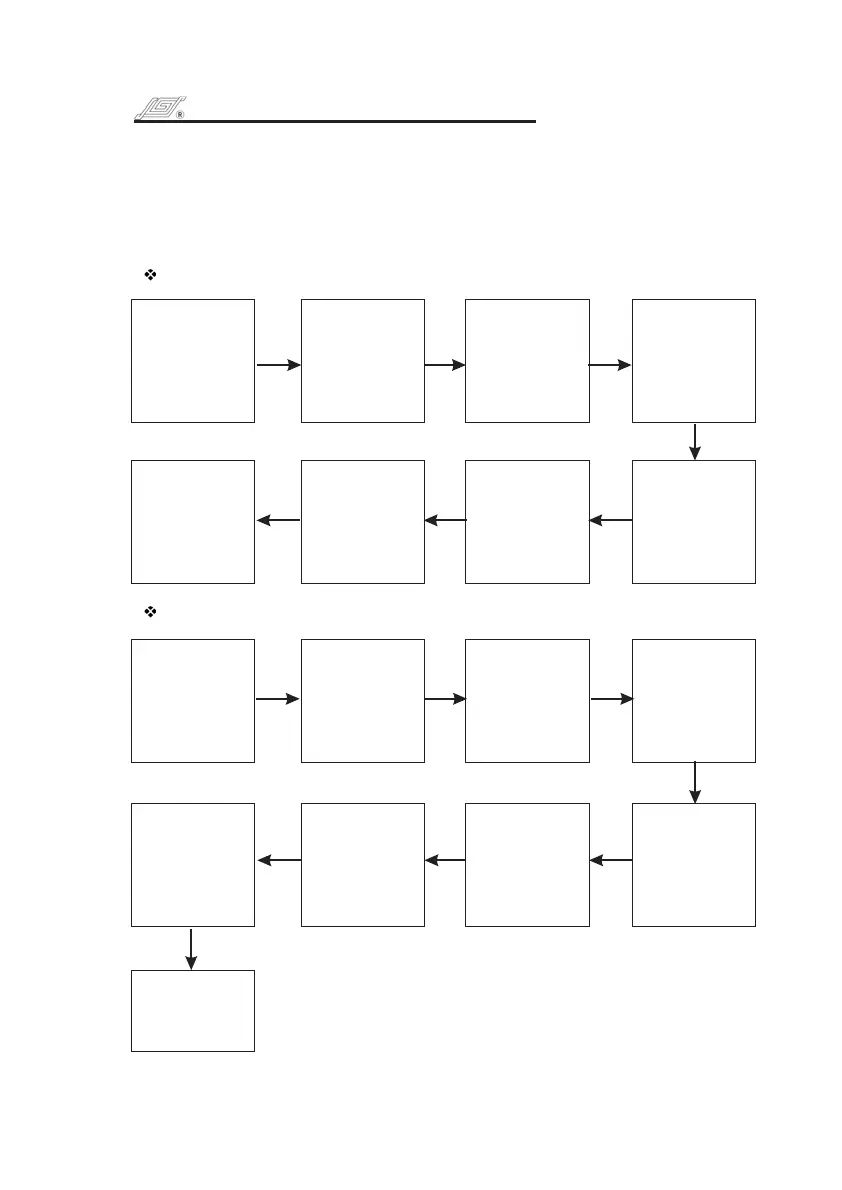

Dispensing Mode operation procedure

Confirm the

volume to be

dispensed

Press to

return to running

interface

Exit Key

Operation Procedure

Select pump head and tubing refer to “Suitable Pump head, Tubing, Ref.

Flow Rate” table before working. Thick wall tubing is preferred for longer

service life.

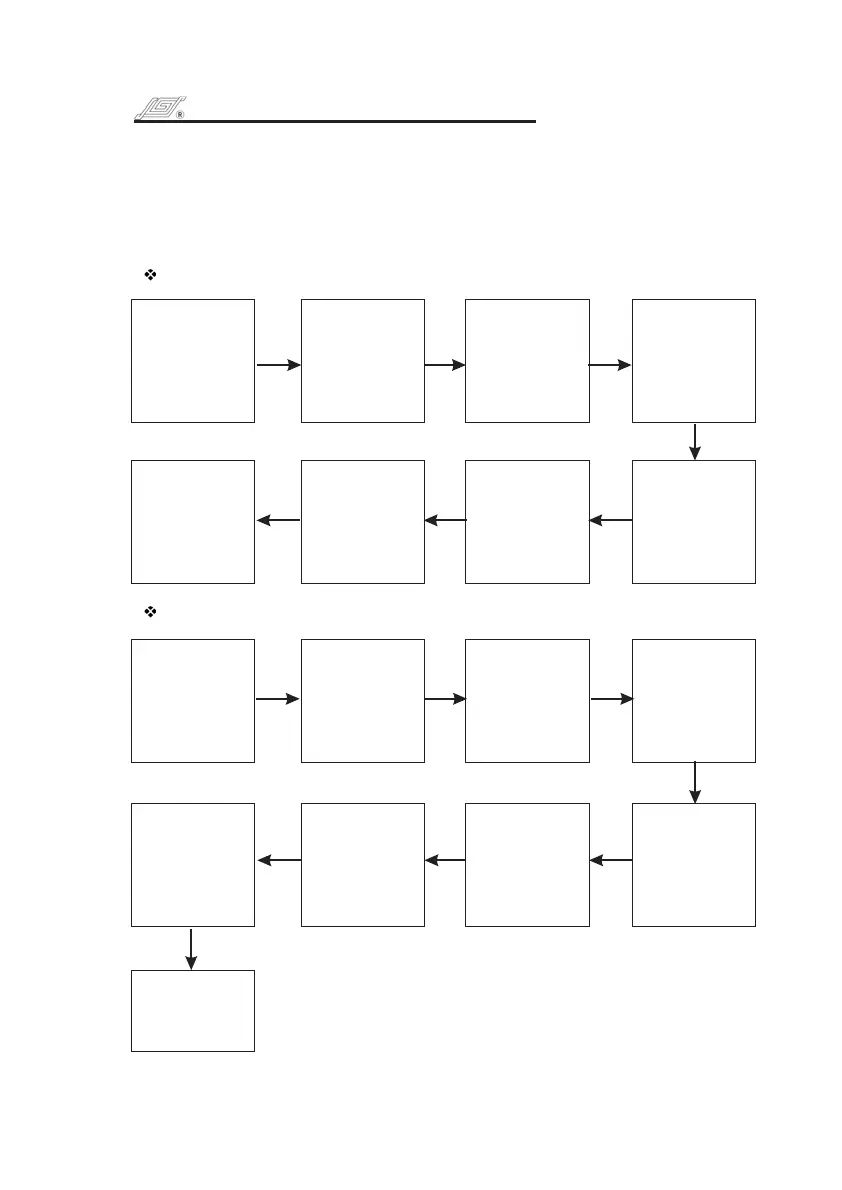

Flow rate mode operation procedure

Confirm the flow

rate of the fluid

which need to be

pumped

Press to

enter

interface

to set pump head

and tubing

Knob

System

Setting

Enter

interface to

select

Control

Mode

Flow Mode

Press to

return to running

interface, turn

to select

needed flow rate

Exit Key

Knob

Press to

enter calibration

selection interface

and select

when

calibration is

needed

Knob

Flowrate

Set ,

press

to start the pump.

Input the actual

volume

Test Time

Start/Stop

Press to

return to running

interface

Exit Key

Select pump

head and tubing

refer to the table

of page 4

Press to

enter

interface

to set pump head

and tubing

Knob

System

Setting

Set

time

Back

Suction

Enter control

mode interface

to select

Dispensing

Enter

interface

to set all the

dispensing

parameters.

Dispense

Setting

Press to

enter calibration

selection

interface and

select

when calibration

is needed

Knob

Dispensing

Press

to start the pump.

Input the actual

volume

Start/Stop

Communication Control RS485

BT100-1F OPERATING MANUAL

BT100-1F OPERATING MANUAL

Loading...

Loading...