10

12 Troubleshooting

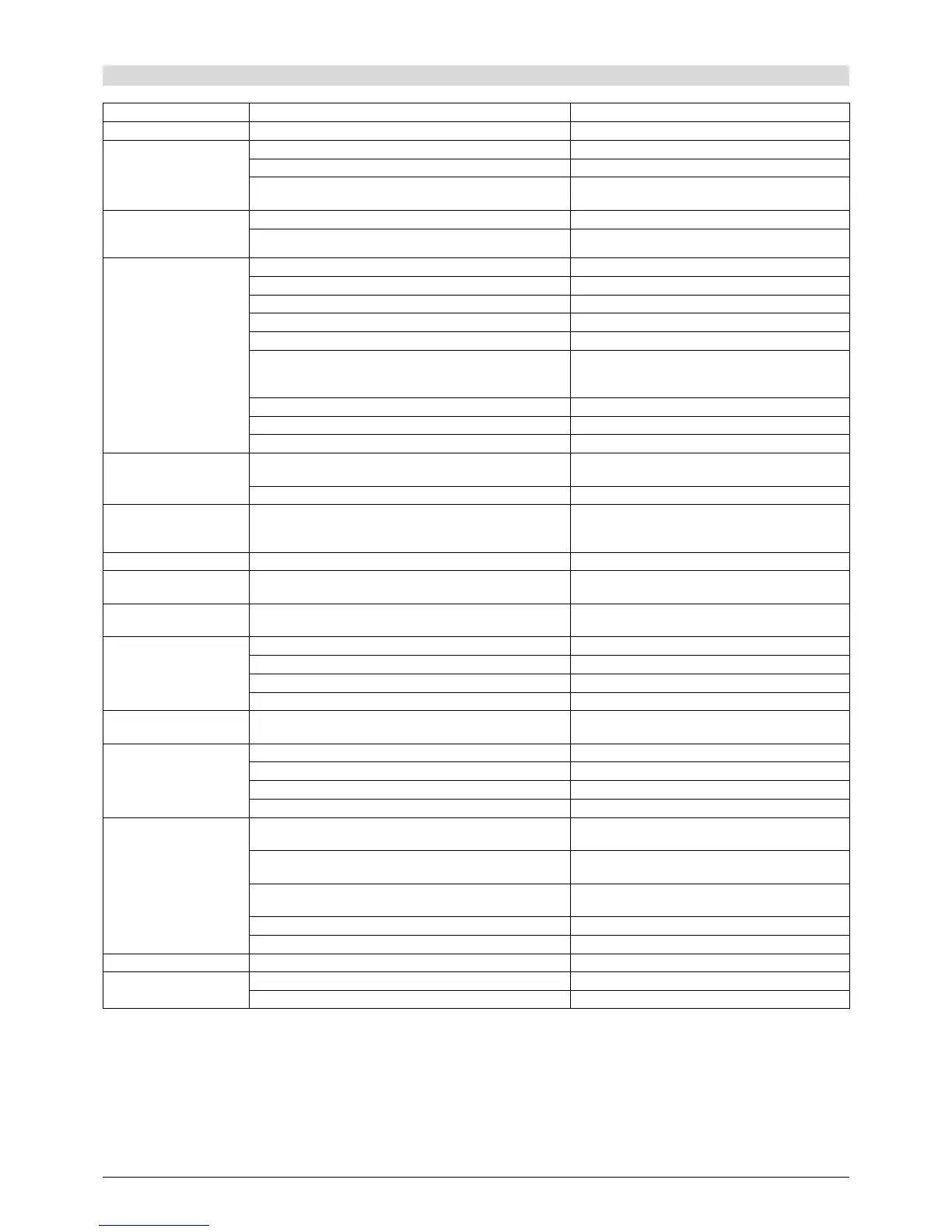

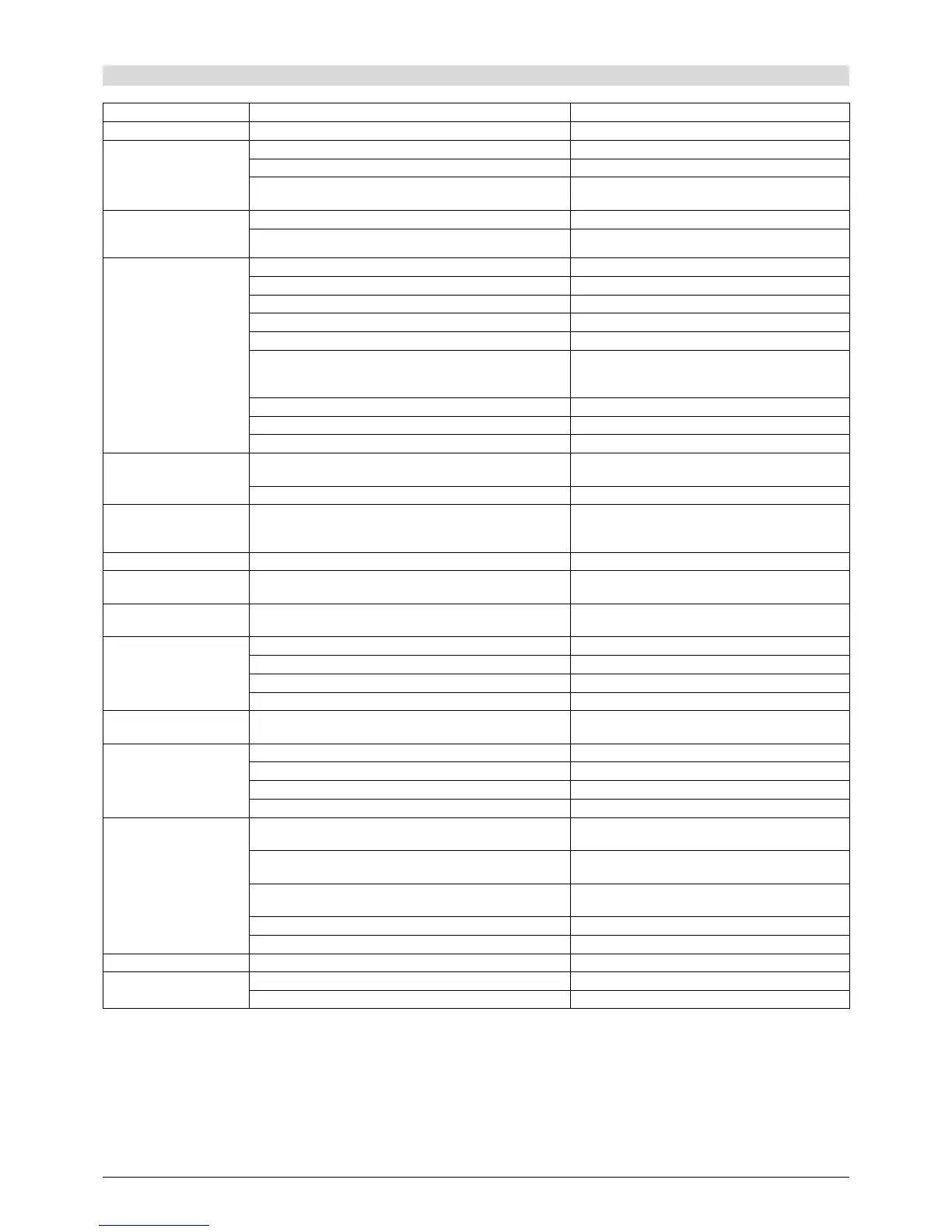

Symptom Cause Remedy

Torch too hot contact tip is not tight check it

No function when torch

button is pressed

nut of the torch hose is not tight tighten it

no connection of the control cable in the torch hose. check and change if necessary

overload of the machine and thermal protection is in

function (control lamp 39 indicates overload)

allow machine to cool down at no load

Irregular wire feeding or

wire welds to the con

-

tact tip

wire electrode is tight at the spool check and change if necessary

burr at the wire beginning cut the wire beginning again

Irregular wire feeding or

no wire feeding

wrong contact pressure at the wire-feed rolls adjust it as described in the manual

torch defect check and change if necessary

no brass pipe in the central connection or is dirty install or clean the brass pipe

bad quality of welding wire check and change if necessary

rust formation at the welding wire check and change if necessary

torch liner is dirty inside disconnect the torch from the machine, screw

off the contact tip and clean the liner with com

-

pressed air

torch liner is dejected check and change if necessary

motor brake adjusted to strong adjust as described in the manual

main rectifier defective check and replace, if required

Machine switches off duty cycle overloaded, control lamp 39 indicates

overload

allow the machine to cool down

to less cooling of machine parts check the air in and outlet

Arc or short circuit be-

tween contact tip and

gas nozzle

spatter built up inside the gas nozzle remove it with special pliers

Unstable arc wrong diameter of contact tip or worn out change contact tip

No function of fan phase missing in the mains check machine at another socket and check

mains and fuses

Mains control lamp 40

does not light

phase missing in the mains check machine at another socket and check

mains and fuses

No shielded gas gas cylinder empty replace it

defect torch check and replace it

pressure reducer dirty or defect check and replace it

valve of gas cylinder defect replace the gas cylinder

Shielding gas switches

not off

valve of gas cylinder dirty or does not close remove torch and pressure reducer and clean it

with compressed air

Not sufficient shielded

gas

wrong adjusted quantity of shielded gas adjust right as described in the manual

dirty pressure reducer check valve

torch, gashose blocked or not air-tight check and change if necessary

shielded gas is blow away from draught avoid draught

Less welding perform-

ance

phase missing check machine at another socket and check

mains and fuses

poor ground connection ensure best contact between ground clamp

and workpiece

ground cable not right plugged in fasten ground cable by turning the plug to the

right

defect torch repair or replace it

main rectifier defective check and replace, if required

Hot plug of ground cable plug was not tightened by turning to the right check

Higher wire wear out at

wire-feeding unit

wire rolls does not fit to the wire diameter install right wire rolls

wrong contact pressure at wire feeding adjust as described at the manual

Loading...

Loading...