page 46

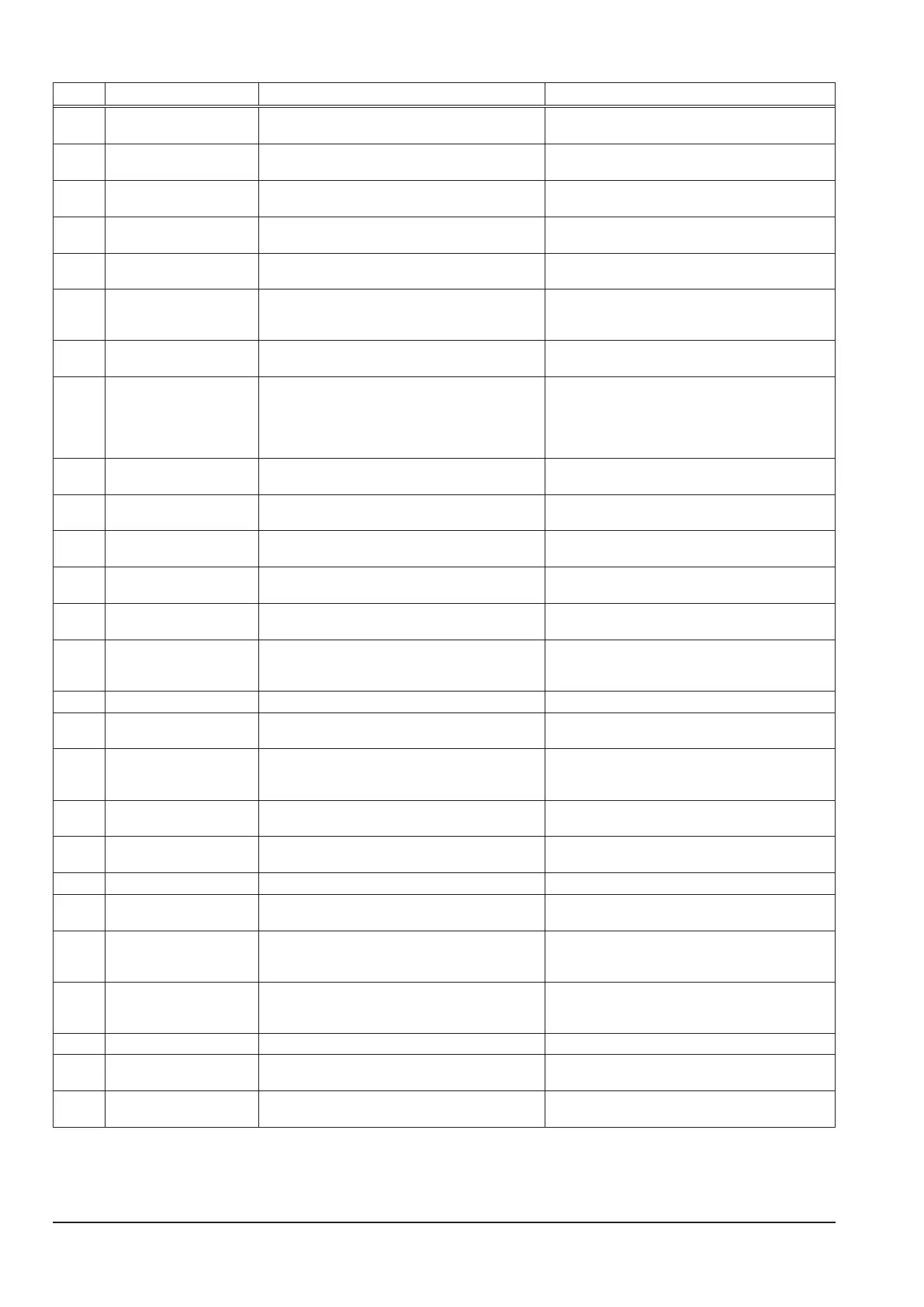

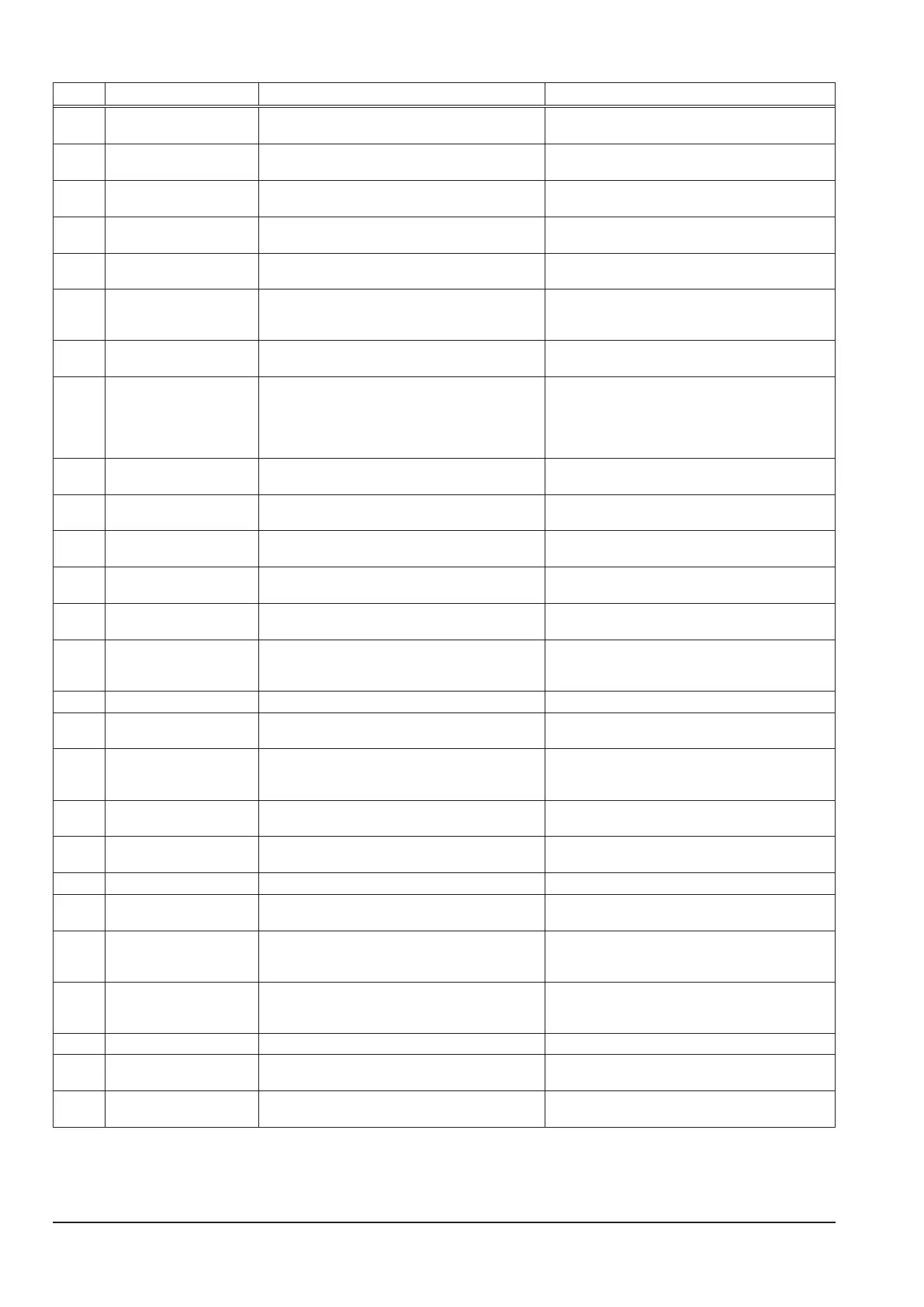

List of error codes

Code designation cause remedy

E 00 no program operating system and welding program doesn’t

match to each other

store welding programs matching to the operating

system version, into the machine

E 01 thermal overload temperature of power units are too high let machine cool down in standby (*1)

see page 32

E 02 mains overvoltage mains voltage too high (24V supply > 36V) check mains voltage and control transformer (*2)

see page 33

E 03 secondary overcurrent welding current is too high check current sensor and its wiring

see page 34

E 05 cooling system error owrate of the cooling liquid is too low

(< 0.3 l/min)"

check connectors of ow-meter, level of cooling

liquid and owrate (*3). See page 36

E 06 secondary overvoltage Master detects output voltage is too high - check power unit

- check ground connection

see page 35

E 07 EEProm checksum error no welding program stored or error during rea-

ding from memory

transfer welding programs to machine again

E 09 V/A measuring error external current/voltage or measure-dierence

between Master and Process

check wiring of current sensor and pc-board DK-

UFI

DC machines: check DK-KSDCN

AC machines: check IGBTs

see page 34 and page 35

E 10 torch connection short circuit of torch control cables or between

torch switch wires and welding potential

check torch control cables and torch interface

see page 38

E 11 remote-control conn. short circuit between remote control cables check remote control and wiring of remote control

socket, see page 39

E 12 Communication Process Process is not responding to Master switch the machine o and on again

optionally exchange pc-board DK-MAPRO

E 13 Temp. sensor error Temp. sensor is defective check resistor value and wiring of the sensor

see page 32

E 14 Op. voltages error supply voltage is too low (24V < 17V) check mains voltage and control transformer (*2)

see page 33

E 16 primary overcurrent

protection1

- power consumption of power unti 1 is too high

- PE protection became active

- check DK-DCDRV and MOSFETs of power unit1

- check ground cable and wiring of power unit

see page 40 and page 45

E 17 Error current symmetry output dierence between power units check power units (*4), see page 34

E 19 Ignition unit error no response of ignition unit to pc-board DK-

MAPRO

check/exchange pc-board DK-HFDC

see page 28

E 20 Overvoltage sec. Process is measuring a too high output voltage or

no voltage at all

check wiring of the output sockets to DK-MAPRO

check power unit

see page 35

E 21 Output voltage/current external current/voltage or measure-dierence

between Master and Process

check wiring of current sensor and pc-board DK-

UFI, see page 34 and page 35

E 22 Mains undervoltage 1 power unit 1 reports mains voltage too low check mains voltage and mains rectier

see page 42

E 23 Mains overvoltage power unit reports mains voltage too high check mains voltage, see page 42

E 24 Overcurrent protection2 power consumption of power unti 2 is too high check DK-DCDRV and MOSFETs of power unit 2

see page 40

E 25 Power module detection Jumper on pc-board DK-DCDRV or pc-board DK-

ACDRV have been set wrong

check Jumper J1, J2 on pc-board DK-DCDRV (by

AC machines check also Jumper 1 on pc-board

DK-ACDRV), see page 43

E26 Synchronisation error communication between the machines is not

working properly

check optical cable between both machines and

settings of each machine (Synchro Master-Slave

setting)

E 29 AC Overvoltage ignition voltage in zero-crossing is too high check IGBTs

E 30 Mains undervoltage 2 power unit 2 reports mains voltage too low check mains voltage and mains rectier

see page 42

E 31 Communication error Master is not responding to Process switch the machine o and on again

optionally exchange pc-board DK-MAPRO

(*1) display the module temperatures in menu Extras > Diagnosis > Module temperatures

(*2) display the supply voltages in menu Extras > Diagnosis > Op. voltages 15V / 24V

(*3) display the ow rate in menu Extras > Diagnosis > Flow rate cooling system

(*4) display the welding current of the mudules in menu Extras > Diagnosis > Current module 1 / 2

Loading...

Loading...