Programmable Logic Controller Installation Guide

XBM-DN32H

XBM/XEM-DN/DP32H2

This installation guide provides simple function information of PLC control. Please read carefully

this data sheet and manuals before using products. Especially read safety precautions and

handle the products properly.

■ Meaning of warning and

caution inscription

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

①

Do not contact the terminals while the power is applied.

② Protect the product from being gone into by foreign metallic matter.

③ Do not manipulate the battery. Charge, disassemble, hitting, short, soldering)

①

Be sure to check the rated voltage and terminal arrangement before wiring.

② When wiring, tighten the screw of terminal block with the specified torque range.

③ Do not install the flammable things on surroundings.

④ Do not use the PLC in the environment of direct vibration.

⑤ Except expert service staff, do not disassemble or fix or modify the product.

⑥ Use the PLC in an environment that meets the general specifications contained

in this datasheet.

⑦ Be sure that external load does not exceed the rating of output product.

When disposing of PLC and battery, treat it as industrial waste.

■ To install, observe the below conditions.

5 ~ 95%RH, non-condensing

5 ~ 95%RH, non-condensing

5

Vibration

Resistance

Frequency Acceleration Amplitude Number

IEC 61131-2

㎐

each

direction

for

X, Y, Z

The following table shows the general specifications of the XGB.

For more information, please refer to user manual.

■ General Specifications

Operation method

Reiterative operation, fixed cycle operation,

Interrupt operation, constant period scan

I/O control method

Batch processing by simultaneous scan(Refresh method),

Directed by program instruction

Processing speed

(Basic instruction)

XBM-H type: 83ns/step, XBM/XEM-H2/HP type: 40ns/step

Program memory

capacity(MK)

H type: 20Kstep, H2/HP Type: 64Ksteps

Program memory

capacity(IEC)

H2/HP type: 384Kbyte

Main + Expansion 7slot

(Communication: max 2slot, High speed I/F: max 2slot )

Delay of operation, abnormal memory, abnormal I/O

Setting latch area at basic parameter

183 days (25

℃

), power off after charging(3.0V)

Built-in function

Cnet(RS-232,RS-485), Enet, PID, High-speed counter,

Positioning

[XBM-H: 2axis, APM]

[XBM/XEM-H2: 2axis, XPM]

1) XG5000 Software

- XBM-DN32H/H2/HP: V4.22 or above

- XEM-DN32H2/HP: V4.26 or above

2) O/S

- XBM-H type: O/S less than V2.0

- XBM-H2/HP type: O/S V2.0 or above

- XEM-H2/HP type: O/S V2.1 or above

■ Check the component in package.

1) XGB-POWER(3P) : Power cable for connecting 24V

■ Check the accessory. Purchase it, if needed,

1) USB-301A : USB connect (download) cable

2) C40HH-□□SB-XBI : Main unit input/output connection

3) XTB-40H(TG7-1H40S) : Main unit input/output Terminal block

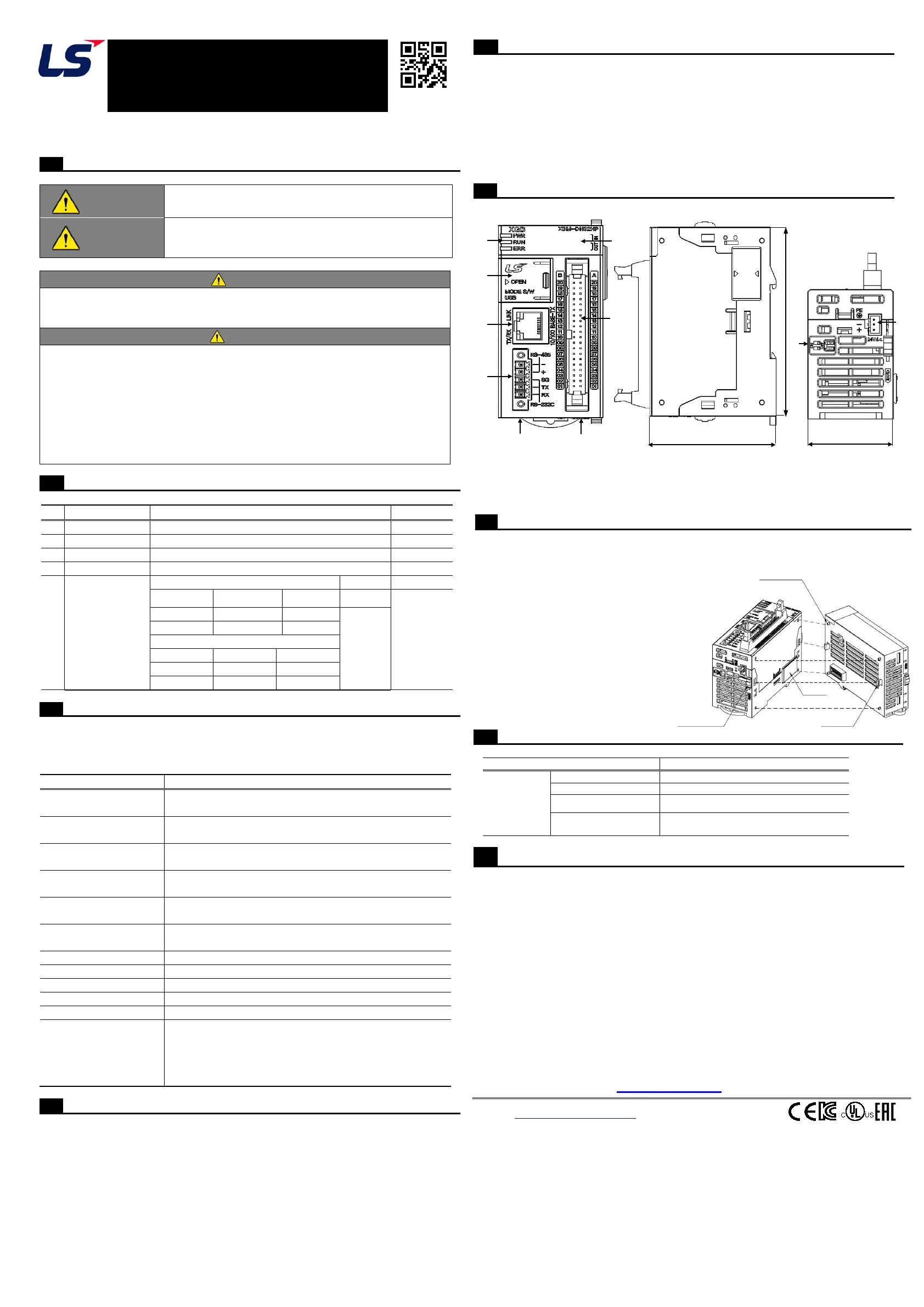

■ This is front part of the CPU. Refer to each name when driving the system. For more

information, refer to user manual.

① Input/ Output indicator LED

② Input/ Output connector

③ Built-in RS-232/485 connecting connector

⑤ Built-in Enet connecting connector

⑧ Termination Resistor Switch

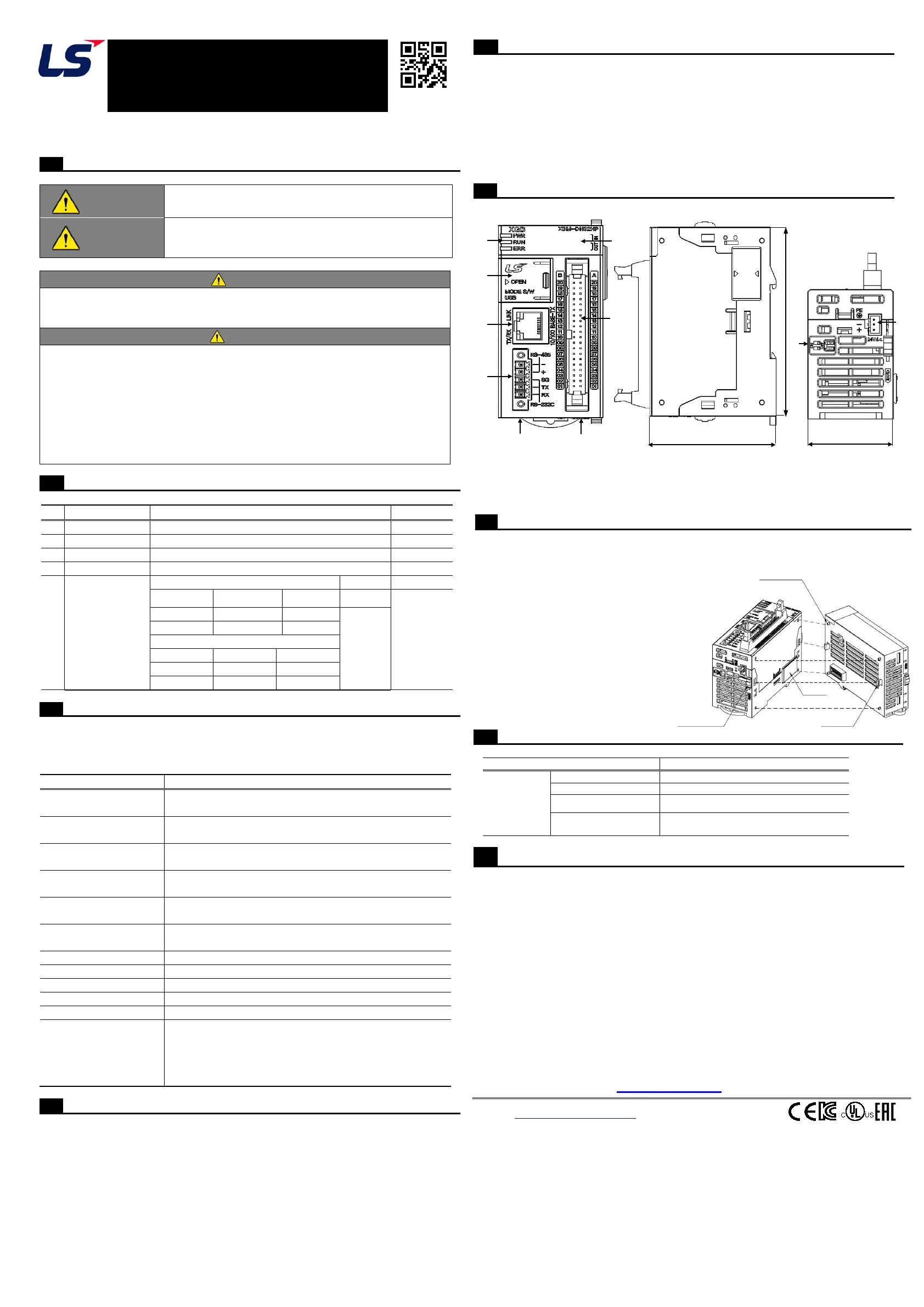

■ Here describes the method to attach and detach each product.

1) Attachment of product

① Eliminate the Extension cover at the right-bottom side of the product.

② Push the product and connect it in

agreement with Hook for fixation of four

edges and Hook for connection at the

bottom.

③ After connection, push down the Hook

for fixation and fix it completely.

2) Detachment of product

① Push up the Hook for connection and

then detach the product with two hands.

(Do not detach the product by force.)

■ Here describes the Power specification of XGB, For more information refer to user manual.

■ Warranty period

18 months after the production date.

■ Scope of Warranty

18-month warranty is available except:

1) The troubles caused by improper condition, environment or treatment except the

instructions of LS ELECTRIC.

2) The troubles caused by external devices

3) The troubles caused by remodeling or repairing based on the user’s own discretion.

4) The troubles caused by improper usage of the product

5) The troubles caused by the reason which exceeded the expectation from science and

technology level when LS ELECTRIC manufactured the product

6) The troubles caused by natural disaster

■ Change in specifications

Product specifications are subject to change without notice due to continuous product

development and improvement.

LS ELECTRIC Co., Ltd. www.lselectric.co.kr 10310001549 V5.5 (2020.4)

• E-mail: automation@lselectric.co.kr

• Factory: 56, Samseong 4-gil, Mokcheon-eup, Dongnam-gu, Cheonan-si, Chungcheongnam-

do, 31226, Korea

Performance Specifications

■ For system configuration, the following version is necessary.

Parts name and Dimension (mm)

Power

Specification

DC20.4~28.8V (-15%, +20%)

Input current

1A (Typ.550㎃)

Permitted momentary

power failure

Less than 1㎳

• Headquarter/Seoul Office

Tel: 82-2-2034-4033,4888,4703

• LS ELECTRIC Shanghai Office (China)

• LS ELECTRIC (Wuxi) Co., Ltd. (Wuxi, China)

• LS-ELECTRIC Vietnam Co., Ltd. (Hanoi, Vietnam)

• LS ELECTRIC Middle East FZE (Dubai, U.A.E.)

• LS ELECTRIC Europe B.V. (Hoofddorf, Netherlands)

• LS ELECTRIC Japan Co., Ltd. (Tokyo, Japan)

• LS ELECTRIC America Inc. (Chicago, USA)

Boss for fixation

Hook for

fixation

Boss for

connection

Expansion

Cover

1549

Loading...

Loading...