UMB communication

Snow depth sensor SHM 31, V2.1 39

Table 15: Measuring channels starting from 5000

9.3. Communication in binary protocol

In this case, communication with the snow depth sensor takes place using the RS485 connection

e.g. with UMB ConfigTool.NET. Please refer to the UMB protocol manual, if desired, for a general

description of communication in the UMB binary protocol over the RS485 interface. The

description of the UMB protocol can be downloaded from the Lufft website at www.lufft.com.

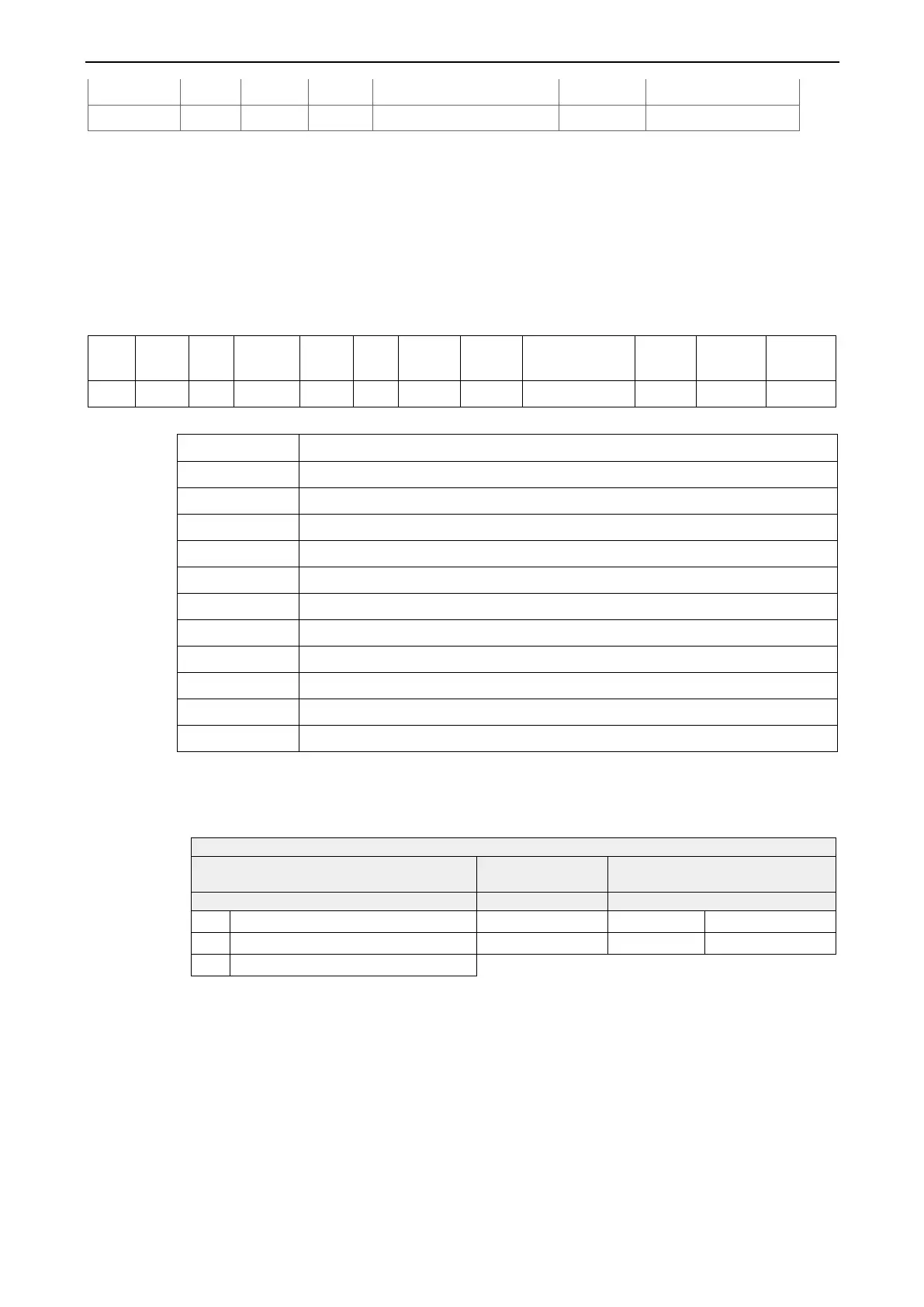

9.3.1. Data frame

The data frame is constructed as follows:

11 ... (8 + len)

optional

Control character for the start of a frame (01h); 1 byte

Header version number, e.g.: V 1.0 <ver> = 10h = 16d; 1 byte

Receiver address; 2 bytes

Number of data bytes between STX and ETX; 1 byte

Control character for the start of payload transmission (02h); 1 byte

Version number of the command; 1 byte

Data bytes; 0 – 210 bytes

Control character for the end of payload transmission (03h); 1 byte

Check sum, 16 bit CRC; 2 bytes

Control character for the end of the frame (04h); 1 byte

Control characters: SOH (01h), STX (02h), ETX (03h), EOT (04h).

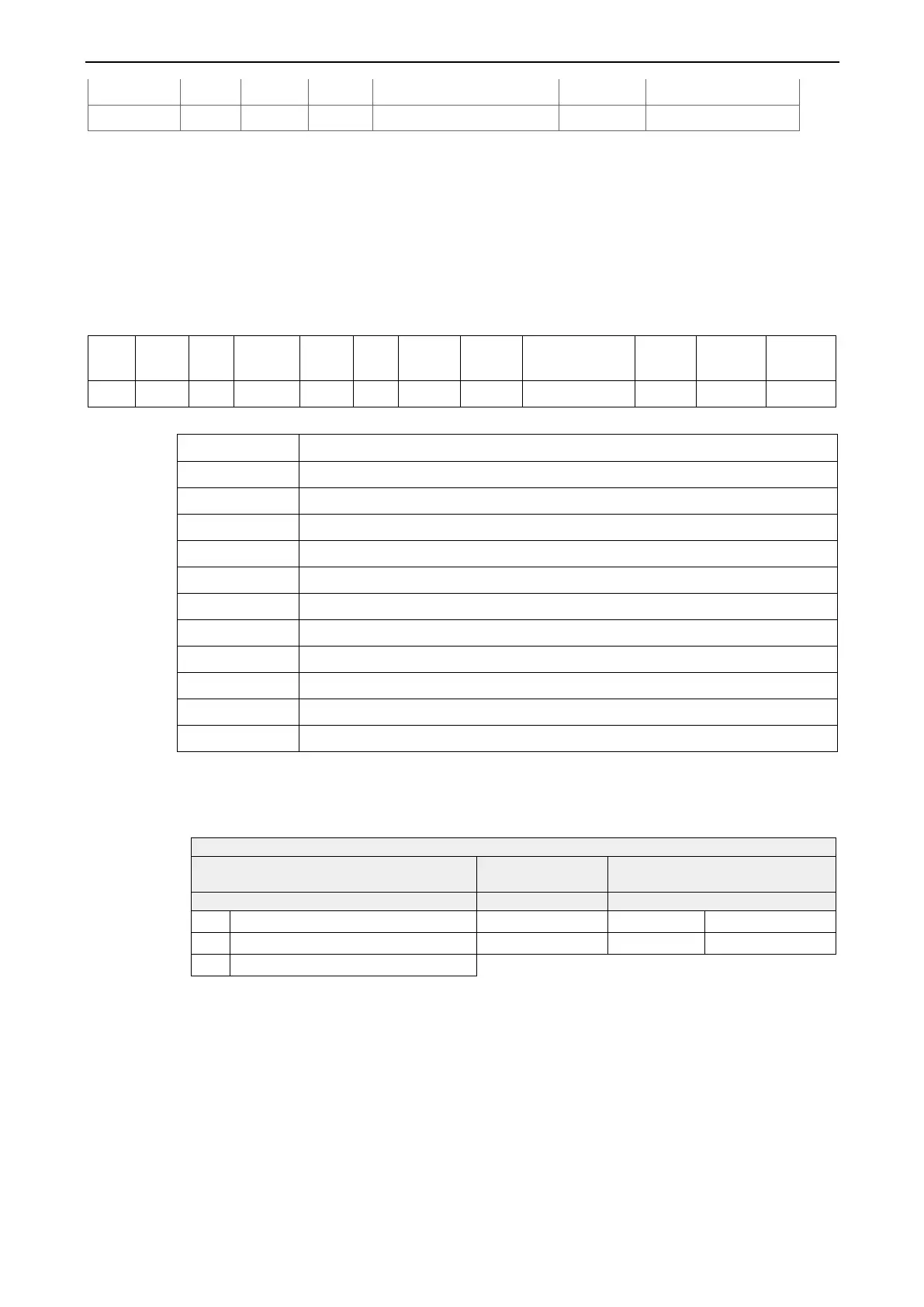

9.3.2. Addressing with class ID and device ID

Addressing is performed using a 16-bit address. This is split into a class ID and a device ID.

Address (2 bytes = 16 bit)

Bits 15 – 12 (upper 4 bits)

Bits 11 – 8

(middle 4 bits)

Bits 7 – 0 (lower 8 bits)

SHM31 Snow Depth Sensor

Master or control devices

ID = 0 is provided as broadcast for classes and devices. Thus, it is possible to transmit a broadcast

on a specific class. However this only makes sense if there is only one device of this class on the

bus; or in the case of a command, e.g. reset.

9.3.3. Example of creating addresses.

If an SHM 31 sensor is to be addressed with the device ID 001, this is done as follows:

The class ID is: 11d = Bh; the device ID is: 001d = 001h

Combining the class ID and the device ID creates the address B001h (45057d).

9.3.4. Example of a binary protocol query

If, for example, a sensor with the device ID 001 is polled from a PC for the current snow depth,

this takes place as follows:

Loading...

Loading...