2-6

CDA3000 Operation Manual

2 Mechanical installation

.

Note the following points:

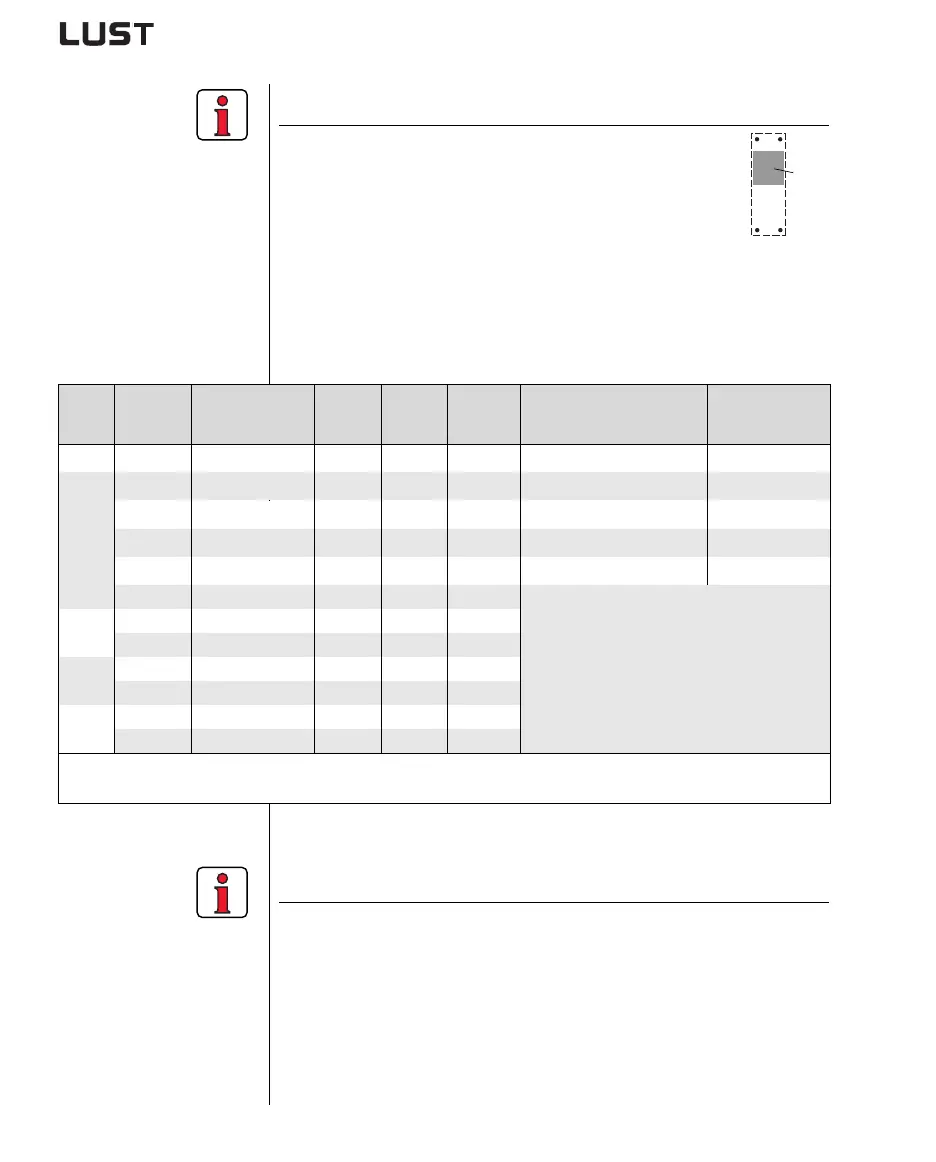

• Cooling can be attained either by a sufficiently large

backing plate (see Table 2.4) or by an additional cooler.

The cooler must be mounted centrally behind the

hottest area (1) of the device.

• The temperature on the rear panel of the inverter

module must not exceed 85.0 °C. At a temperature

> 85° C the device shuts down automatically. It can only be

restarted when it has cooled.

• Required evenness of contact surface = 0.05 mm, maximum

roughness of contact surface = roughness factor 6.3

(1)

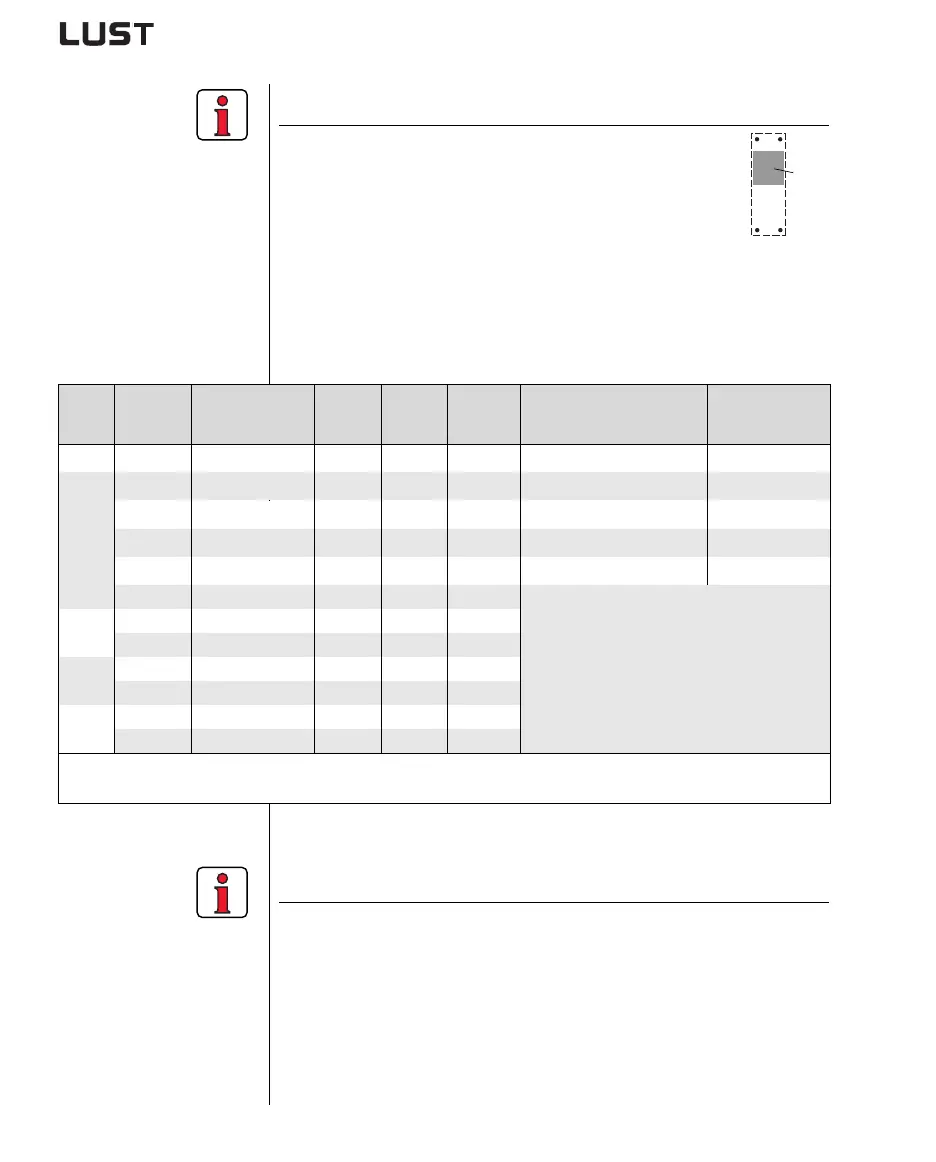

Size Power Inverter module

P

V

at

4 kHz

P

V

at

8/16 kHz

R

thK

3)

[K/W]

Backing plate (unvarnished

steel min. cooling surface

Ambient

temperature

BG1 0.75 kW CDA32.004,Cx.x 48 W 55 W 0.05 650x100mm = 0.065m²

45°C

1)

, 40°C

2)

BG2

1.1 kW CDA32.006,Cx.x 75 W 82 W 0.05 650x460mm = 0.3m²

45°C

1)

, 40°C

2)

1.5 kW CDA32.008,Cx.x 95 W 105 W 0.05 650x460mm = 0.3m²

45°C

1)

, 40°C

2)

0.75 kW CDA34.003,Cx.x 55 W 70 W 0.05 None

45°C

1)

, 40°C

2)

1.5 kW CDA34.005,Cx.x 80 W 112 W 0.05 650x460mm = 0.3m²

45°C

1)

, 40°C

2)

2.2 kW CDA34.006,Cx.x 106 W 148 W 0.05

An additional cooler is required to supply

adequate cooling.

Project planning notessee appendix A.4

If you have any further questions please

consult your project engineer.

BG3

3.0 kW CDA34.008,Cx.x 135 W 162 W 0.03

4.0 kW CDA34.010,Cx.x 172 W 207 W 0.03

BG4

5.5 kW CDA34.014,Cx.x 210 W 268 W 0.02

7.5 kW CDA34.017,Cx.x 255 W 325 W 0.02

BG5

11 kW CDA34.024,Cx.x 315 W 400 W 0.015

15 kW CDA34.032,Cx.x 400 W 510 W 0.015

1) At a power stage clock frequency of 4 kHz 2) At a power stage clock frequency of 8 kHz

3) Thermal resistance between active cooling surface and cooler

Table 2.4 Required cooling with cold plate

Note the following points:

• The backing plate must be grounded over a large area.

• For mounting in switch cabinets with convection (= heat loss is

discharged to the outside via the cabinet walls) an internal air

circulation fan must always be fitted.

• The best result for effective EMC installation is attained with a

chromated or galvanized backing plate. If backing plates are

varnished, the coating must be removed in the area of the contact

surface!

Loading...

Loading...