22

0698-050 B70V/B70V-SR - 04/19

en

The eccentric screw drum pumps type B70V are used

to pump from mobile vessels ammable liquids, which

belong to the explosion groups IIA and the temperature

classes T1 to T4.

The external part of the pump tubes between suction

orice and pressure joint corresponds to category 1.

The external part of the pump tubes between the pres-

sure joint and the connecting part for a drive motor and

the internal part of the pump tubes in MS variants (cov-

ered by the pumped liquid in case of intended delivery)

correspond to category 2.

When the drum pump is used, all additional compo-

nents tted to the connecting part (coupling, gear, drive

motor, etc.) have to be outside of the mobile container.

In this respect, the requirements of unit group II (sub-

class II A), category 2, temperature class T4 have to be

met.

It has to be ensured that only a stator made of PTFE is

built-in.

the 75.1 size must not be used to pump am-

mable uids.

The drive motor (electrical or with compressed air

drives) may not exceed an output of 1.0 kW and a speed

of 900 1/min.

The drum pump must not be employed for non-mobile

operation. The operation of the pump has to be moni-

tored during the pumping process so that dry running

and empty running phases are restricted to the abso-

lutely minimum.

Before starting up the pump, an equipotential bonding

must be established between the pump, the container

to be emptied and the container to be lled.

The potential between the pump and the container to

be emptied is equalized by connecting the equipotential

bonding cable (order no. 0204-994). Paint and dirt

should be removed from the connecting points in order

to improve the conductivity.

The conductive connection between the full and empty

containers is achieved by means of a conductive sub-

strate (e.g. conductive gratings).

The transition between container and earthing must

also be conductive.

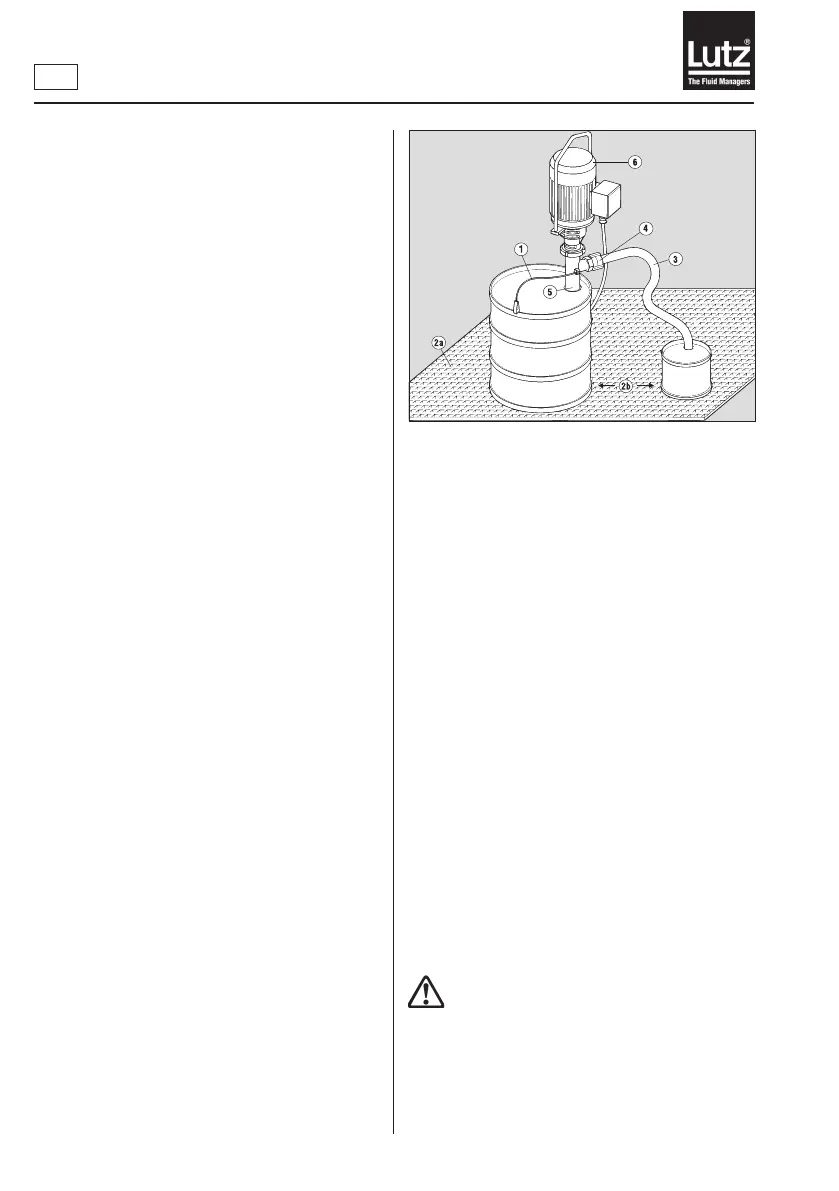

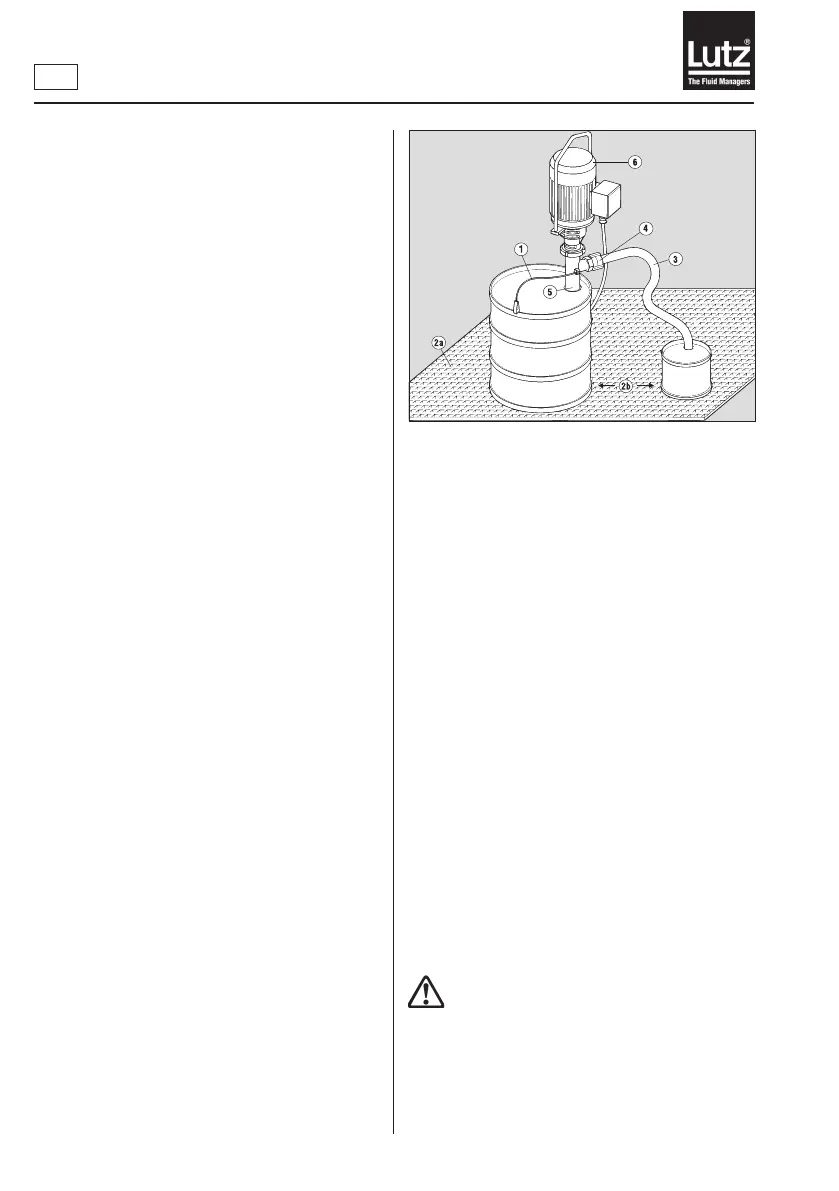

(1) Equipotential bonding cable, (2a) Conductive sub-

strate or connection of an equipotential bonding cable

to each of the two drums, (2b) Galvanic connection (low

contact resistance towards earth), (3) Conductive hose,

(4) Conductive connection between hose and hose con-

nector, (5) pump tube category 1/2, (6) explosion proof

motor

Anyway the hose connected to the pressure joint of the

drum pump must be suciently electrically conductive

– with respect to electrostatic charges.

The ohmic resistance between the ttings – in this

case between the pump tube and the nozzle – may not

exceed a limited value depending on the respective

hose type.

1. Identication of the hose with the symbol “M”

Limited value ≤ 10

2

Ω

2. Identication of the hose with the symbol „Ω“

Limited value ≤ 10

6

Ω

The hose connection must ensure a highly conductive

transition between hose and pump tube, as well as be-

tween hose and nozzle.

If this is not the case, all conducting parts (such as the

metal mouth piece at the end of the hose) shall have to

be earthed separately.

Connecting of conductive hoses with armatures

to the hose lines requires the identication and

examination to DIN EN 12 115.

Loading...

Loading...