10

en

0698-401 MD1xL / MD2xL - 08/2020

4. Starting up

4.1 Compressed air connection

!

WARNING

Danger of injury due to uncontrolled restarting of the motor!

►Switchingothemotorbeforeconnectingthecompressedair.

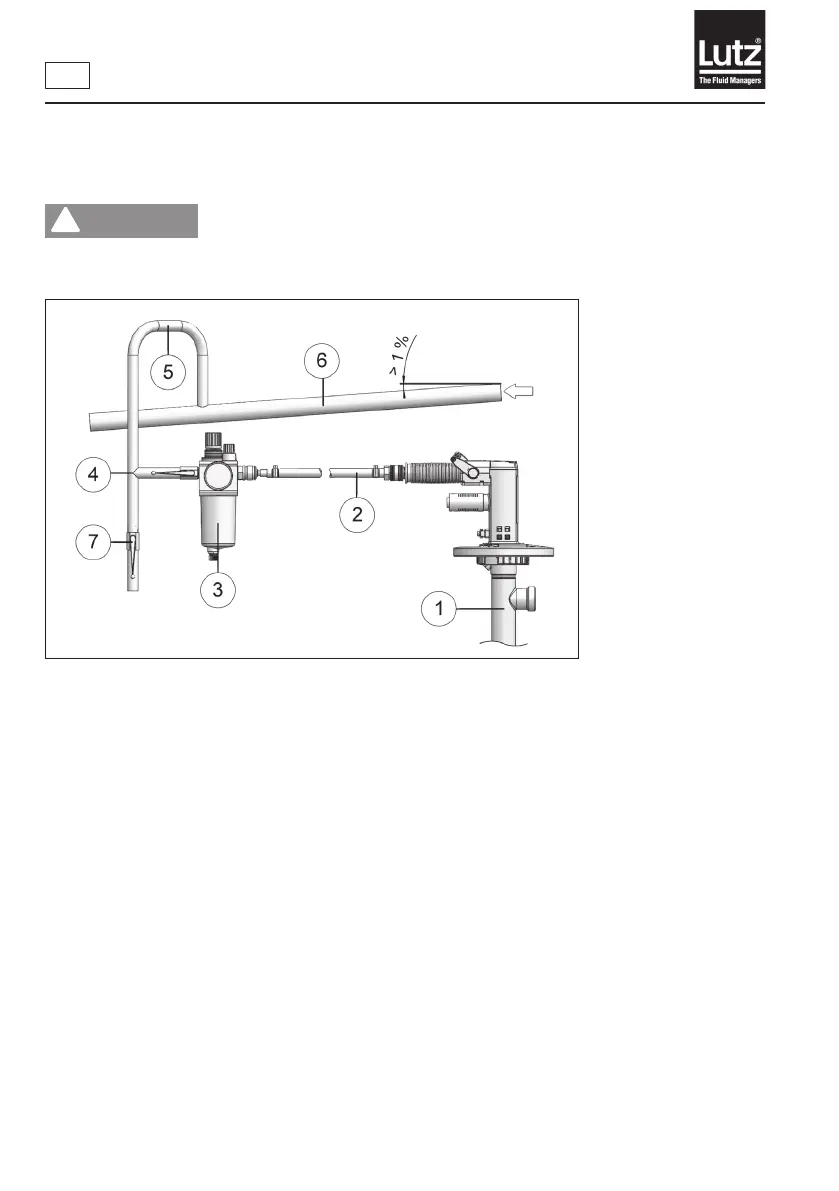

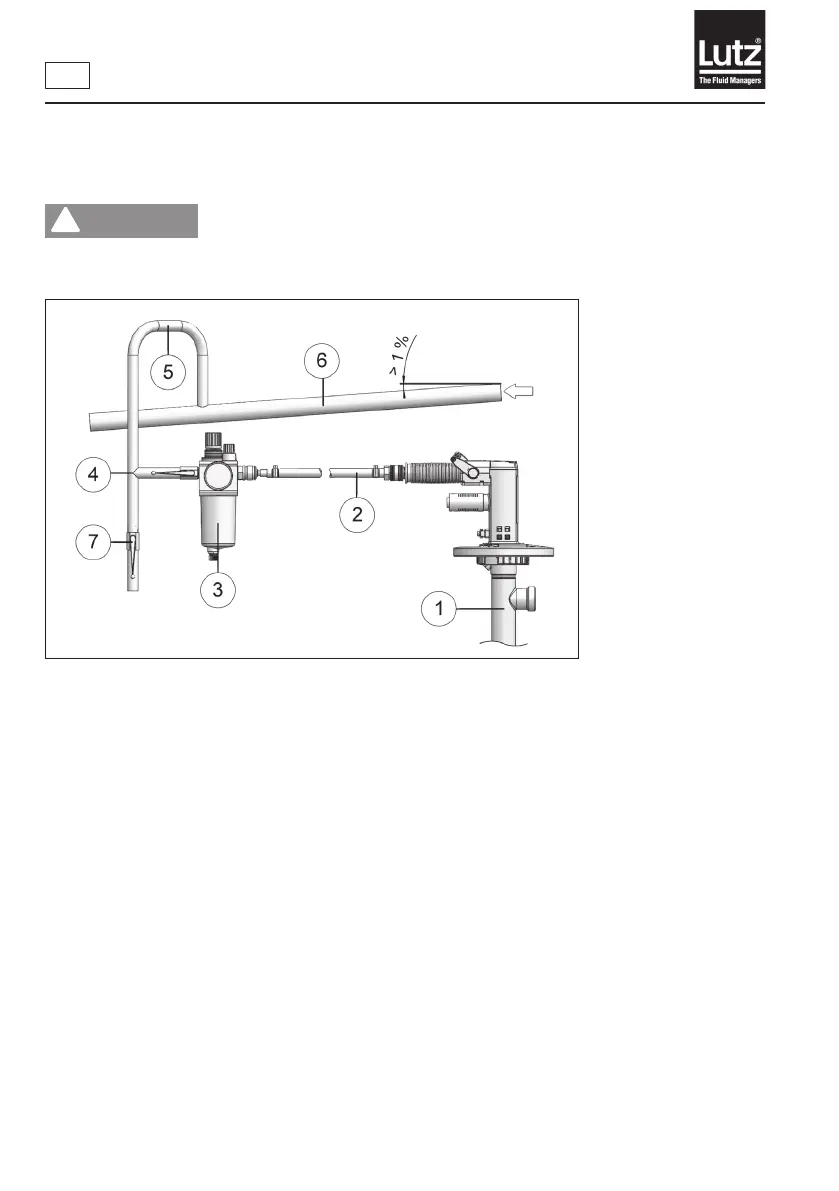

Fig. 1

Function and service life largely depend on the condition and pressure of the compressed air supplied.

Excessive moisture or dirt particles in the compressed air will destroy the motor. A high percentage of

condensateinthecompressedairwillcauseaslightrustdepositinthemotorandtheairoutletmuer

will get covered by ice during air expansion.

Therefore, when starting the compressed air motor, observe the following items (→Fig.1):

• Before connecting the motor to the compressed air supply, clean the compressed air line and the hose

by blowing out with low pressure to remove any dirt particles from the line. Wear safety goggles, hold

thelinetightanddonotstandintheareaoftheairow.

• Mainairlines(6)requireaslightinclinationofatleast1%inthedirectionofowsothatcondensation

watermaybedrainedthroughavalve(7)atthelowestpoint(manuallyorautomatically).

• Branchpipesshouldbeconnectedpointingupwards(5)inthecaseofahorizontalmainline(6)-and

inthecaseofaverticalmainline(4)notatthelowestpoint.Thus,anycondensationwatercollectedin

themainlinewillbepreventedfromowingintothebranch.

• Usemaintenanceunits(3)consistingofairlterandoiler.TheoilerisnotnecessaryformotorsMD1xL

andMD2xL,butisrecommendedforlongerservicelife.Themotorpoweris10-20%lowerwithnon

lubricated air than with lubricated air.

Loading...

Loading...